Epoxy foamed sandwich composite material and preparation method thereof

A technology of epoxy foam and composite materials, which is applied in the field of foam sandwich composite materials and polymer sandwich materials, and can solve the problems that do not involve sound insulation, heat insulation, damping, vibration reduction, and noise reduction epoxy foam sandwich composite materials. and other problems to achieve the effect of reducing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

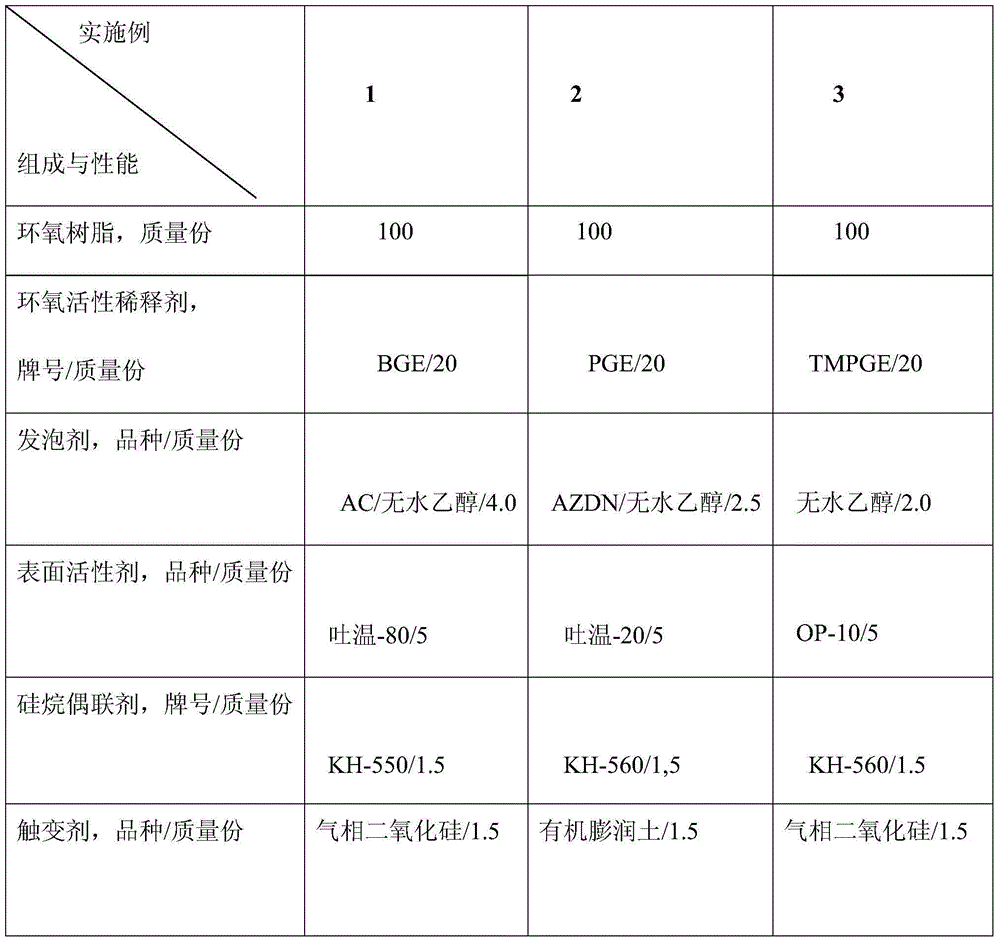

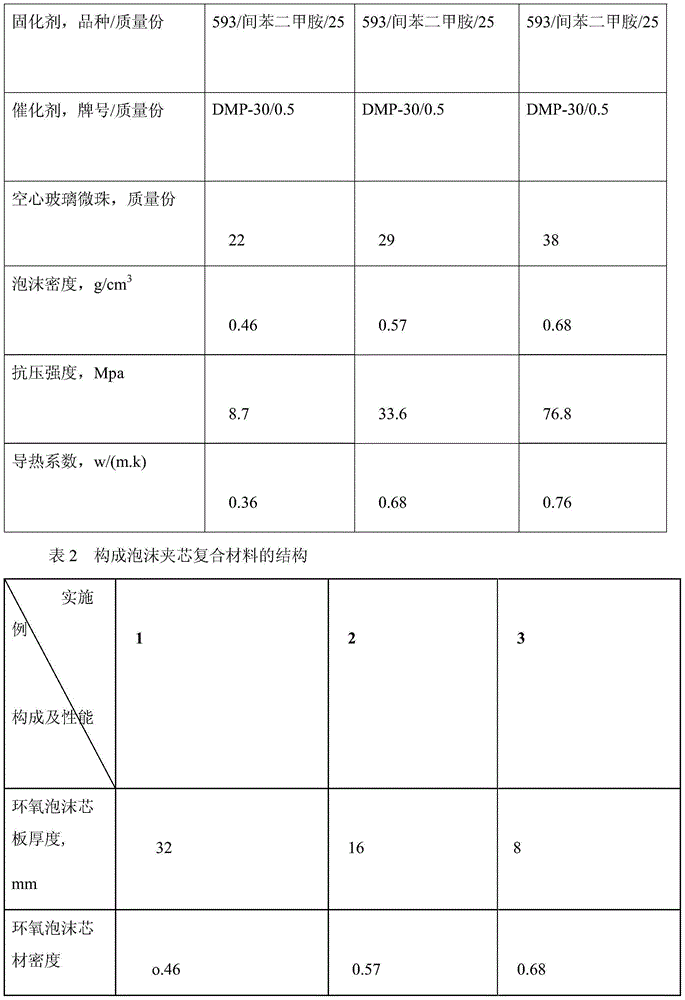

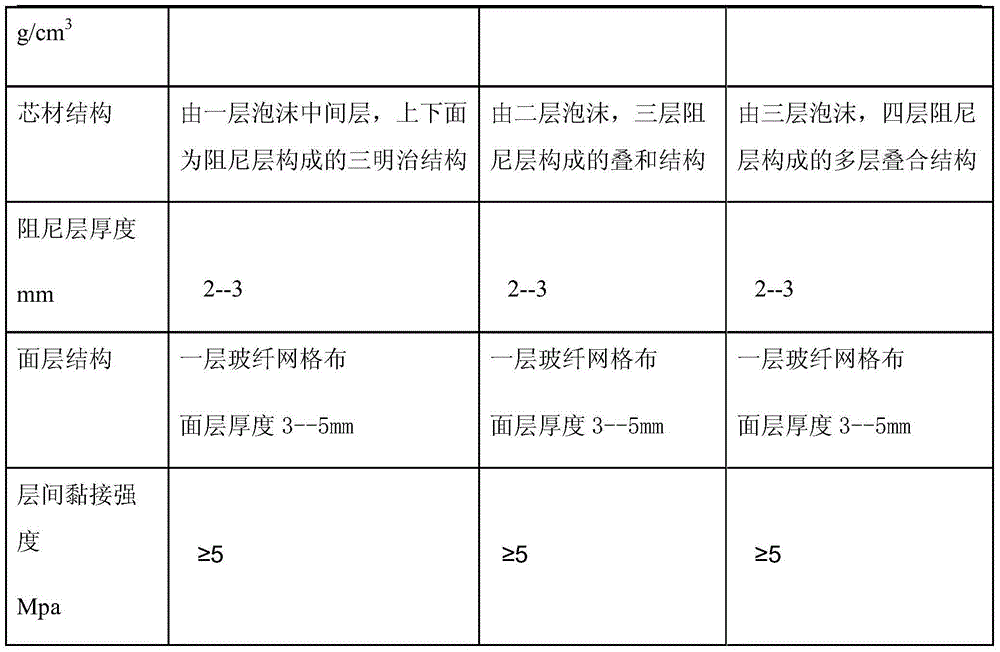

[0066] Examples 1-3 The composition and performance of the epoxy foam core material and the structure of the foam sandwich composite material are listed in Table 1 and Table 2.

[0067] Table 1 Composition and properties of epoxy foam core material

[0068]

[0069]

[0070]

[0071] Example 1 foam sandwich composite material in the table, with azodicarbonamide (AC, main foaming agent) and dehydrated alcohol (auxiliary foaming) as foaming agent, polyoxyethylene sorbitan monooleate (Tween 80) surfactant, hollow glass microsphere mass fraction 22, foam density 0.46g / cm 3 The thickness of the foam core board is 32mm. The core structure is a layer of foam middle layer, the upper and lower layers are damping layers, forming a sandwich structure, and the surface layer is glass fiber mesh reinforced epoxy glass steel with a thickness of 3-5mm. Interlayer bond strength ≥ 5Mpa.

[0072] Example 2 foam sandwich composite material in the table, with azobisisobutylcyanide (AZDN...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com