Sandwich-structured composite graphene paper electrode material preparation method

A technology of composite graphite and electrode materials, applied in hybrid capacitor electrodes, hybrid/electric double-layer capacitor manufacturing, nanotechnology for materials and surface science, etc., can solve the problem of decreasing the proportion of active substances, increasing electrode resistance, and reducing active substances Utilization and other issues, to achieve good support, increase flexibility, and promote the effect of electron transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

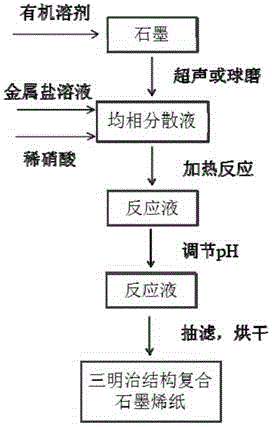

Method used

Image

Examples

Embodiment 1

[0021] (1) Add 30ml ethylene glycol in the cryptocrystalline graphite of 0.0210g, and carry out ball-milling stripping 8h to it, obtain stable homogeneous dispersion liquid;

[0022] (2) Take by weighing 1.0389g cobalt nitrate and be dissolved in 20ml ethanol;

[0023] (3) adding the metal salt solution in step (2) to (1), and adding 30ml of dilute nitric acid (25%);

[0024] (4) react the solution in step (3) at 120° C. for 6 h, adjust the pH to 9 after the reaction, and continue stirring for 2 h;

[0025] (5) The solution in step (4) is filtered through a microporous membrane to carry out layer-by-layer self-assembly, and after each washing with deionized water and ethanol for 3 times, it is dried at low temperature to form a sandwich structure composite graphene paper electrode material;

[0026] (6) Calcining the electrode material obtained in step (5) at 150° C. for 1 h, and then soaking it in the electrolyte solution to be tested for 12 h after calcining.

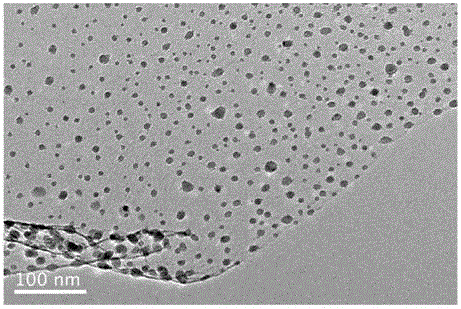

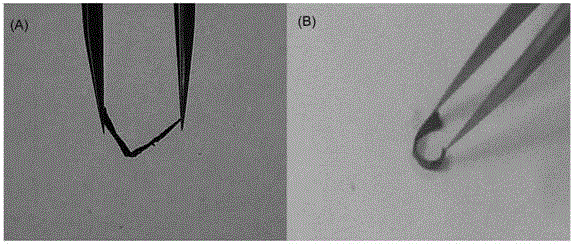

[0027] The ...

Embodiment 2

[0029] (1) Add 30ml of N-methylpyrrolidone to the flake graphite of 0.0300g, and carry out ball milling and peeling off for 8h to obtain a stable homogeneous dispersion;

[0030] (2) take by weighing 1.8320g nickel nitrate and be dissolved in the 20ml ethanol;

[0031] (3) adding the metal salt solution in step (2) to (1), and adding 25ml of dilute nitric acid (30%);

[0032] (4) react the solution in step (3) at 130° C. for 4 hours, adjust the pH to 9 after the reaction, and continue to stir for 2 hours;

[0033] (5) The solution in step (4) is filtered through a microporous membrane to carry out layer-by-layer self-assembly, and after each washing with deionized water and ethanol for 3 times, it is dried at low temperature to form a sandwich structure composite graphene paper electrode material;

[0034] (6) Calcining the electrode material obtained in step (5) at 100° C. for 1 h, and then soaking it in the electrolyte solution to be tested for 8 h after calcining.

[0035...

Embodiment 3

[0037] (1) Add 30ml of n-butanol to the dense crystalline graphite of 0.0450g, and carry out ball milling and peeling off for 8h to obtain a stable homogeneous dispersion;

[0038] (2) take by weighing 5.454g ferric nitrate and be dissolved in the 20ml n-butanol;

[0039] (3) adding the metal salt solution in step (2) to (1), and adding 40ml of dilute nitric acid (30%);

[0040] (4) react the solution in step (3) at 115° C. for 8 hours, adjust the pH to 8 after the reaction, and continue to stir for 2 hours;

[0041] (5) The solution in step (4) is filtered through a microporous membrane to carry out layer-by-layer self-assembly, and after each washing with deionized water and ethanol for 3 times, it is dried at low temperature to form a sandwich structure composite graphene paper electrode material;

[0042] (6) Calcining the electrode material obtained in step (5) at 170° C. for 0.5 h, and then immersing it in the electrolyte solution to be tested for 16 h after calcining. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Specific capacitance value | aaaaa | aaaaa |

| Specific capacitance value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com