Foamed aluminum material of Kagome honeycomb core structure as well as preparing method and application thereof

A honeycomb sandwich structure and honeycomb structure technology, which is applied in the field of aluminum foam Kagome honeycomb sandwich structure material and its preparation, can solve the problems of poor overall heat dissipation and achieve good application prospects, good energy absorption and heat dissipation, and weight reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention also includes the preparation method of above-mentioned aluminum foam Kagome honeycomb sandwich structure material, and described preparation method comprises the following steps:

[0043] S1. After heating and melting the alloy aluminum into a melt, add a tackifier and a foaming agent under stirring;

[0044] S2, cooling and solidifying the melt treated in step S1 before the foaming agent foams, and then grinding the solid into powder;

[0045] S3. Add the powder obtained in the step S2 into the prefabricated Kagome honeycomb structure mold, heat and melt, heat-preserve and foam, and cool to obtain the aluminum foam Kagome honeycomb sandwich structure material.

[0046]As can be seen from the above description, the beneficial effects of the present invention are: the present invention skillfully combines the advantages of foamed aluminum and honeycomb, and the foamed aluminum Kagome honeycomb sandwich structure material of the present invention no...

Embodiment 1

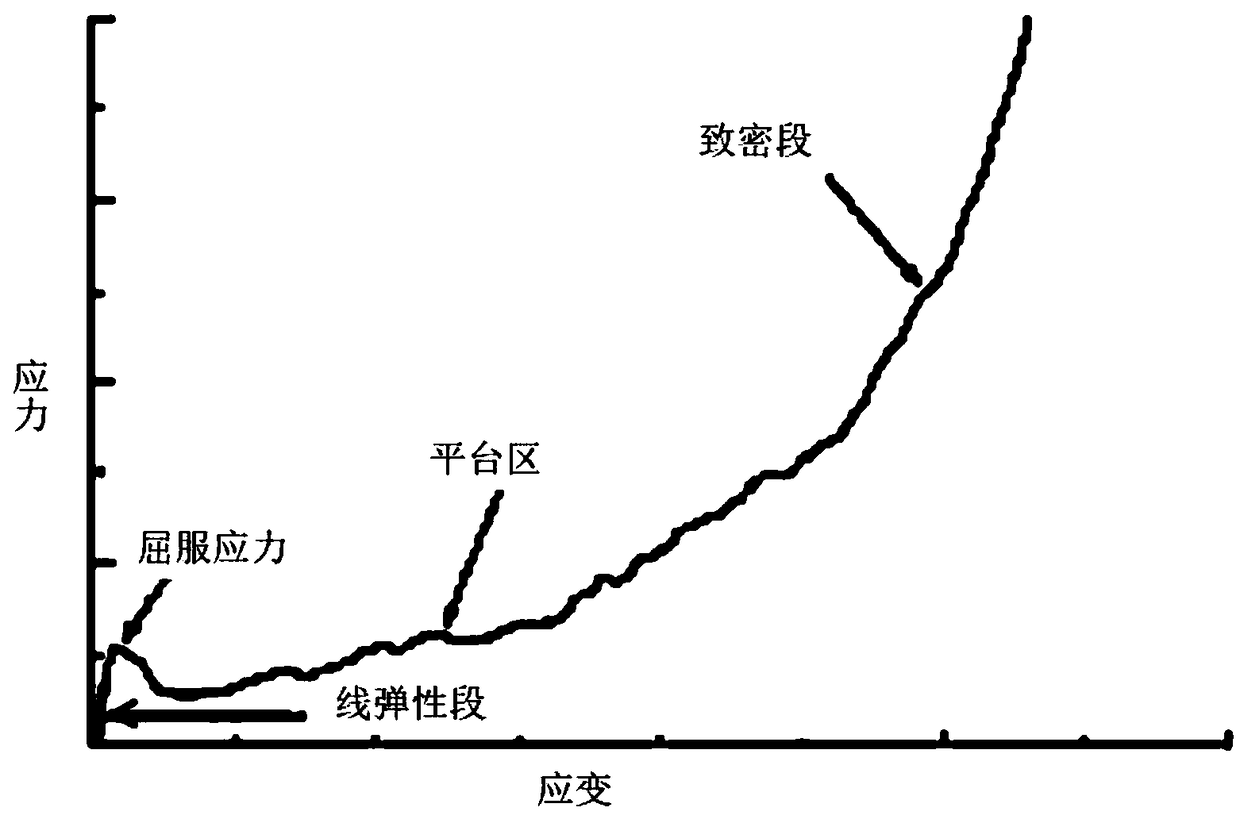

[0085] Embodiment 1 (relative density is 0.31) and 2 (relative density is 0.16) the relationship between the stress-strain and the relative density of the aluminum foam Kagome honeycomb sandwich structure material that makes, as Figure 5 shown by Figure 5 It can be seen that as the relative density increases, the yield stress of the material also increases relatively, but the maximum strain in the compressed to dense section decreases, and the greater the relative density, the greater the strength of the material.

[0086]b) Dynamic compression performance and its influencing factors test experiment:

[0087] As an impact protection material, its application often needs to withstand high-speed deformation, and the impact load has a short time and high impact strength. Therefore, the compression performance under dynamic load is obviously different from that of quasi-static conditions. Take Examples 1-4 Conduct dynamic compression performance test experiments.

[0088] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com