A kind of preparation method of sandwich structure composite graphene oxide paper electrode material

A composite oxidation and electrode material technology, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., can solve the problems of reducing the utilization rate of active materials, increasing electrode resistance, and reducing the proportion of active materials, so as to promote electron transfer, Increase flexibility, good support effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

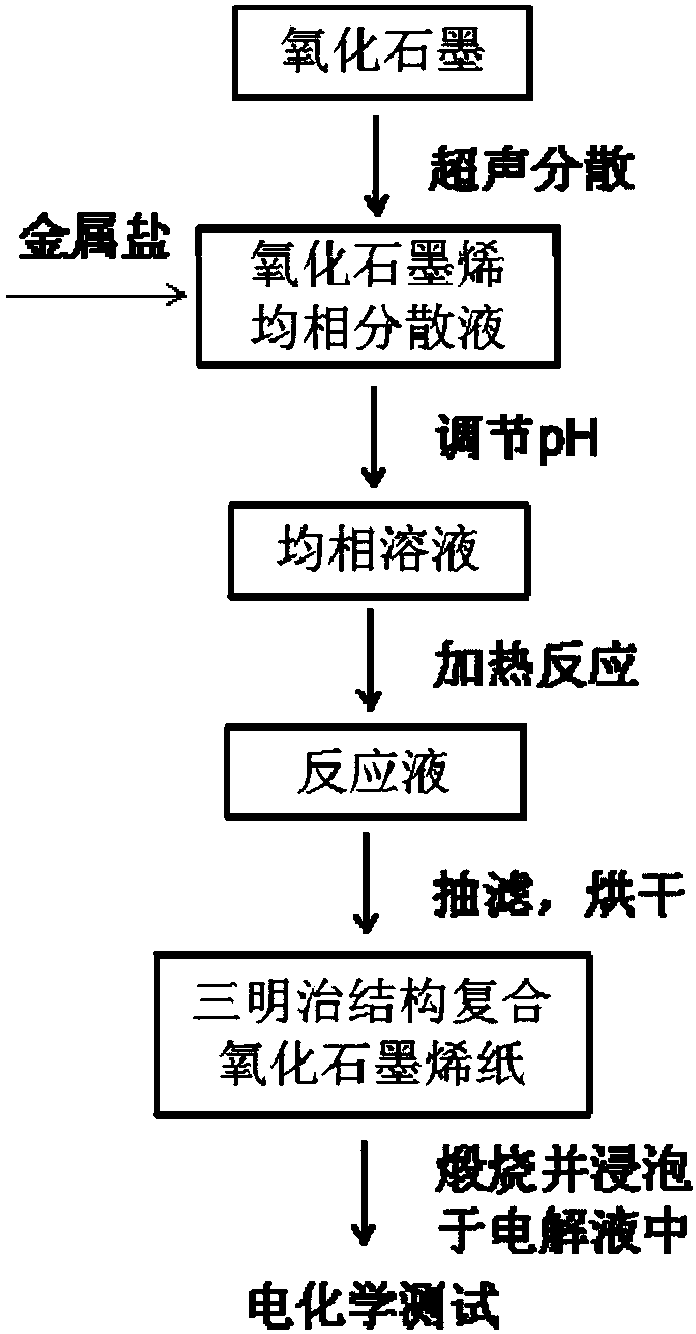

Method used

Image

Examples

Embodiment 1

[0019] (1) Weigh 0.0250g of graphite oxide (oxygen content 15%) in 50ml of ethanol to ultrasonically disperse it completely for 1h;

[0020] (2) take by weighing 1.0913g cobalt nitrate and stir to dissolve completely in graphene ethanol solution;

[0021] (3) adjusting the pH of the homogeneous solution in step (2) to 9, and reacting at 80° C. for 10 h;

[0022] (4) filtering the solution in step (3) through a microporous membrane to carry out layer-by-layer self-assembly, washing three times with deionized water and ethanol, and drying at low temperature to form a sandwich-structure composite graphene oxide paper electrode material;

[0023] (5) The electrode material obtained in step (4) was calcined at 150° C. for 1 h, and then soaked in the electrolyte to be tested for 12 h after calcination.

[0024] The sandwich structure composite graphene oxide paper prepared in Example 1 is used as the electrode material of supercapacitor, and a higher specific capacitance is obtaine...

Embodiment 2

[0026] (1) Weigh 0.1500g of graphite oxide (oxygen content 25%) in 50ml of ethylene glycol by ultrasonic for 2h to make it completely dispersed;

[0027] (2) take by weighing 12.474g nickel chloride and stir to dissolve completely in graphene ethylene glycol solution;

[0028] (3) adjusting the pH of the homogeneous solution in step (2) to 8, and reacting at 130° C. for 8h;

[0029] (4) filtering the solution in step (3) through a microporous membrane to carry out layer-by-layer self-assembly, washing three times with deionized water and ethanol, and drying at low temperature to form a sandwich-structure composite graphene oxide paper electrode material;

[0030] (5) The electrode material obtained in step (4) was calcined at 100° C. for 1 h, and then immersed in the electrolyte to be tested for 8 h after calcination.

[0031] The sandwich structure composite graphene oxide paper prepared in Example 2 is used as the electrode material for supercapacitors, and a higher specifi...

Embodiment 3

[0033] (1) Weigh 0.0750g of graphite oxide (oxygen content 40%) in 50ml ethylene glycol / water mixed solution by ultrasonic for 1h to disperse it completely;

[0034] (2) take by weighing 4.1813g manganese sulfate and stir to dissolve completely in graphene glycol / water mixed solution;

[0035] (3) adjusting the pH of the homogeneous solution in step (2) to 10, and reacting at 100° C. for 12 hours;

[0036] (4) filtering the solution in step (3) through a microporous membrane to carry out layer-by-layer self-assembly, washing three times with deionized water and ethanol, and drying at low temperature to form a sandwich-structure composite graphene oxide paper electrode material;

[0037] (5) The electrode material obtained in step (4) was calcined at 170° C. for 0.5 h, and then soaked in the electrolyte to be tested for 16 h after calcination.

[0038] The sandwich structure composite graphene oxide paper prepared in Example 3 was used as the electrode material for supercapaci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com