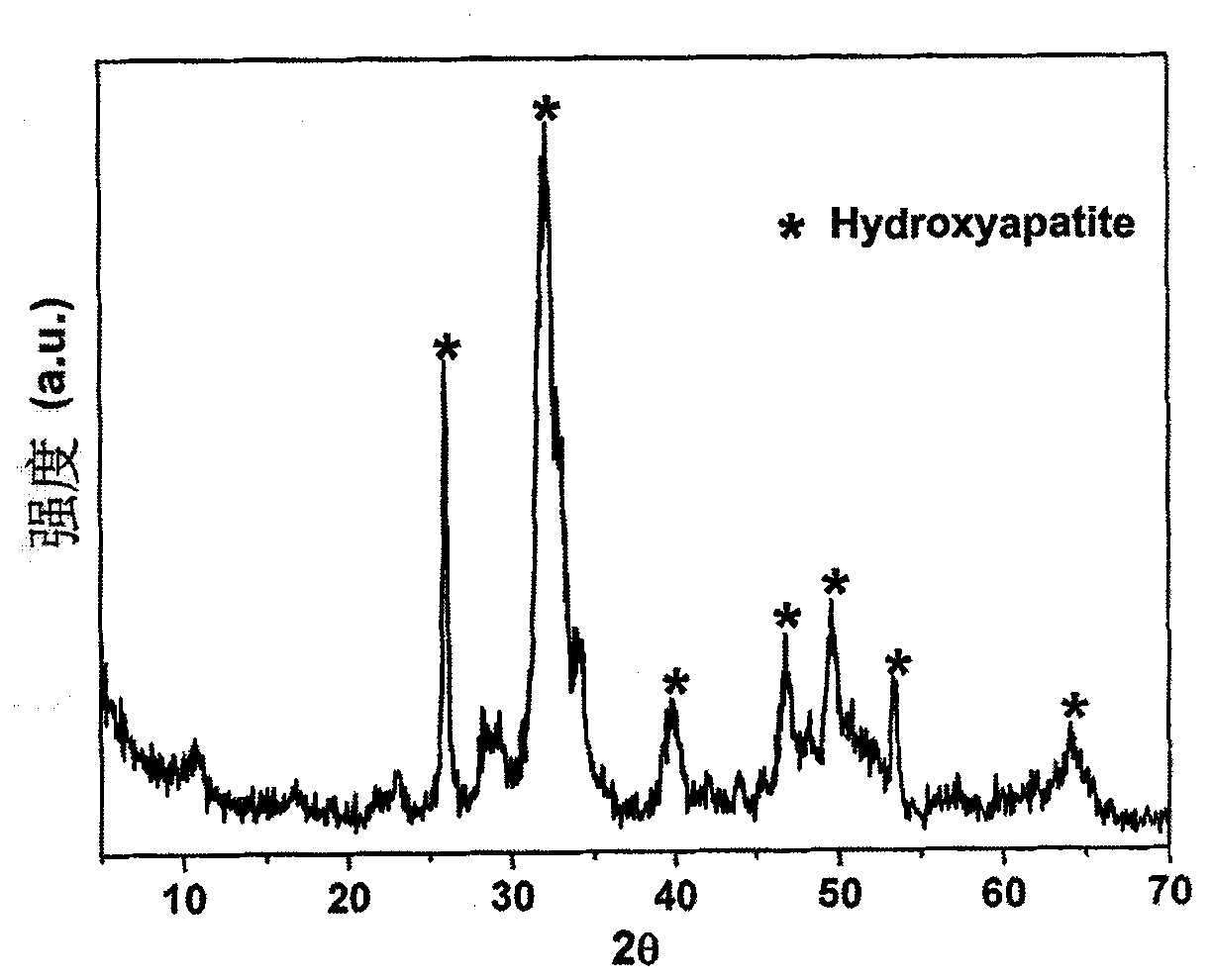

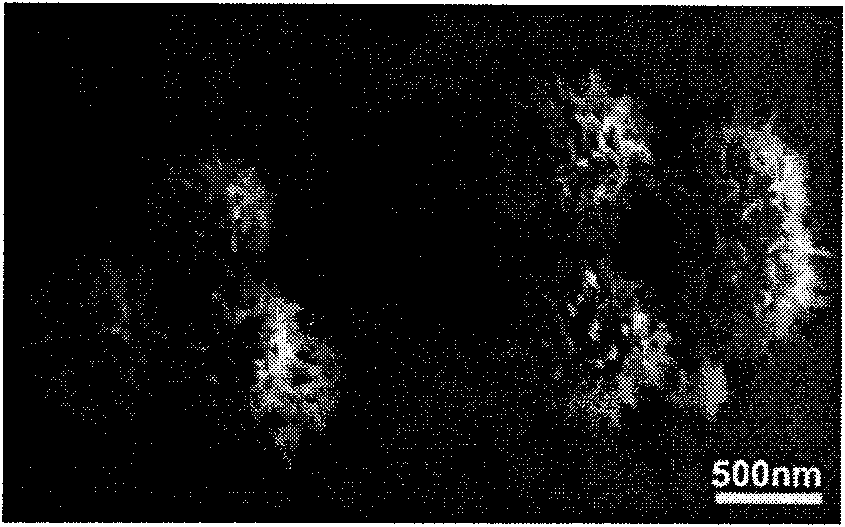

Hydroxyapatite hybridized nanometer crystal assembly, preparation method and application thereof

A technology of hydroxyapatite and nanocrystals, applied in nanostructure manufacturing, chemical instruments and methods, nanotechnology, etc., can solve problems such as uneven size distribution, easy agglomeration of particles, poor stability and dispersion of water phase, etc., to overcome size The effect of uneven distribution, uniform size dispersion, and obvious increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] In this example, the process steps for preparing the hydroxyapatite hybrid nanocrystal assembly are as follows:

[0045] (1) Preparation of hyaluronic acid solution

[0046] Add 0.6kg of hyaluronic acid with a molecular weight of 2.2 million to a reaction vessel filled with 60L of deionized water at normal pressure and room temperature, and dissolve the hyaluronic acid completely under stirring;

[0047] (2) ion slow release diffusion

[0048] Under stirring, it is the Na of 0.36mol / L that the hydrogen phosphate concentration is added in the hyaluronic acid aqueous solution prepared in step (1). 2 HPO 4 2H 2 O aqueous solution 20L to form hyaluronic acid-Na 2 HPO 4 2H 2 O mixed liquor, adjust the pH value of described mixed liquor with the ammoniacal liquor of concentration 0.5mol / L and the HCl of concentration 0.5mol / L, make the pH value of mixed liquor stabilize at 10;

[0049] CaCl with a calcium ion concentration of 0.5 mol / L 2 Put 20L of aqueous solution in...

Embodiment 2

[0054] In this example, the process steps for preparing the hydroxyapatite hybrid nanocrystal assembly are as follows:

[0055] (1) Preparation of Hyaluronic Sodium Hyaluronate Solution

[0056] Add 0.6g of sodium hyaluronate with a molecular weight of 1.8 million to a reaction vessel filled with 60mL of deionized water at normal pressure and room temperature, and completely dissolve the sodium hyaluronate under stirring;

[0057] (2) ion slow release diffusion

[0058] Under stirring, add calcium ion concentration to the sodium hyaluronate aqueous solution prepared in step (1) and be the CaCl of 0.39mol / L 2 Aqueous solution 20mL to form sodium hyaluronate-CaCl 2 For the mixed solution, adjust the pH value of the mixed solution with ammonia water with a concentration of 0.2 mol / L and HCl with a concentration of 0.2 mol / L, so that the pH value of the mixed solution is stabilized at 10;

[0059] The hydrogen phosphate concentration is 0.3mol / L (NH 4 ) 2 HPO 4 2H 2 O aqueo...

Embodiment 3

[0064] In this example, the process steps for preparing the hydroxyapatite hybrid nanocrystal assembly are as follows:

[0065] (1) Preparation of hyaluronic acid solution

[0066] Add 0.06g of hyaluronic acid with a molecular weight of 6 million to a reaction vessel containing 20mL of deionized water at normal pressure and room temperature, and dissolve the hyaluronic acid completely under stirring;

[0067] (2) ion slow release diffusion

[0068] Under stirring, add CaCl with a calcium ion concentration of 1mol / L to the hyaluronic acid solution prepared in step (1). 2 Aqueous solution and K with a hydrogen phosphate concentration of 0.83 mol / L 2 HPO 4 ·3H 2 O aqueous solution 10mL each to form hyaluronic acid-CaCl 2 -K 2HPO 4 ·3H 2 O mixed liquor, adjust the pH value of described mixed liquor with the ammoniacal liquor of concentration 0.5mol / L and the HCl of concentration 0.5mol / L, make the pH value of mixed liquor stabilize at 10;

[0069] The hyaluronic acid-CaCl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com