Preparation method for heavy metal negative ion-removed porous nanometer composite fiber membrane

A technology of nanocomposite fibers and nanofiber membranes, applied in the fields of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc. Easy to reunite, difficult to recycle and other problems, to meet the requirements of emergency treatment, high adsorption capacity, easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

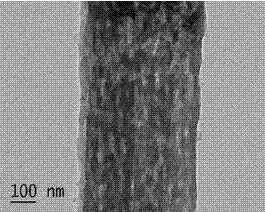

[0039] A porous nanocomposite fiber membrane X1 for removing heavy metal anions is prepared by the following method:

[0040]1) Weigh 0.9g of polyacrylonitrile and 4.5g of polyethylene glycol into 10mL of N,N-dimethylformamide, stir well, transfer to a glass syringe, and set the spinning voltage of the spinning equipment to 13kv , the flow rate is 0.8mL / h, the collection distance is 15cm, the nanofiber membrane matrix is prepared by high-voltage electrospinning technology, soaked in ultrapure water ultrasonically, washed to remove the residual porogen, and then dried to prepare a porous nanofiber membrane matrix , this matrix is marked as X10;

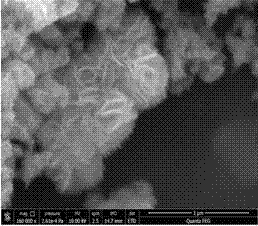

[0041] 2) Weigh 1g of ammonium molybdate, 1g of thioacetylammonium and 0.25g of silicotungstic acid, put them in a mixed solvent (volume ratio of 1:1) prepared by 50mL of ethanol and water, ultrasonically dissolve and mix well, and seal the solution. And put it in a constant temperature drying oven, raise the temperature to 180°C,...

Embodiment 2

[0045] A porous nanocomposite fiber membrane X2 for removing heavy metal anions is prepared by the following method:

[0046] 1) Weigh 1.5g of polyacrylonitrile and 3.75g of polyethylene glycol into 10mL N,N-dimethylformamide, stir evenly, transfer to a glass syringe, set the spinning voltage to 18kV, the spinning liquid The flow rate is 1.6mL / h, and the collection distance is 20cm. The nanofiber membrane matrix is prepared by high-voltage electrospinning technology, soaked in ultra-pure water ultrasonically, washed to remove the residual porogen, and then dried to prepare a porous nanofiber membrane matrix;

[0047] 2) Weigh 2g of ammonium molybdate, 2g of thioacetylammonium and 0.5g of silicotungstic acid, put them in a mixed solvent (volume ratio of 1:1) prepared by 50mL of ethanol and water, ultrasonically dissolve and mix well, and seal the solution. And put it in a constant temperature drying oven, raise the temperature to 200°C, perform a hydrothermal reaction for 12 ...

Embodiment 3

[0051] A porous nanocomposite fiber membrane X3 for removing heavy metal anions is prepared by the following method:

[0052] 1) Weigh 2g of polyacrylonitrile, add 1g of polyethylene glycol into 10mL N,N-dimethylformamide, stir evenly, transfer to a glass syringe, set the spinning voltage to 25kV, and the flow rate of the spinning liquid to 2.5mL / h, the collection distance is 25cm, the nanofiber membrane matrix is prepared by high-voltage electrospinning technology, soaked in ultrapure water ultrasonically, washed to remove the residual porogen, and then dried to prepare a porous nanofiber membrane matrix;

[0053] 2) Weigh 3g of ammonium molybdate, 3g of thioacetamide ammonium and 1g of silicotungstic acid, put them in 50mL of ethanol and water mixed solvent (1:1 volume ratio), ultrasonically dissolve and mix well, seal the solution, and Place in a constant temperature drying oven, heat up to 240°C, perform hydrothermal reaction for 24 hours, cool to room temperature, wash ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com