Preparation method of bentonite inorganic gel with photocatalysis activity

A technology of inorganic gel and bentonite, which is applied in chemical instruments and methods, catalysts for physical/chemical processes, treatment of dyed low-molecular-weight organic compounds, etc. Achieve the effect of overcoming easy reunion and expanding practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

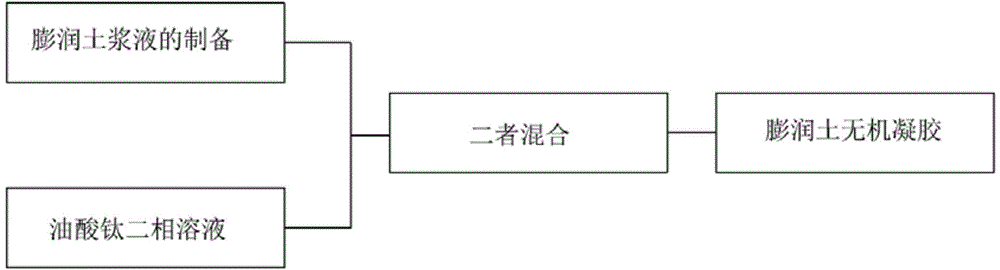

[0021] Example 1. The preparation method of bentonite inorganic gel with photocatalytic properties, the preparation method consists of the following steps: (1) Preparation of modified bentonite slurry: mix bentonite and surfactant in a mass ratio of 1:1, In the state of stirring, add petroleum ether or n-hexane and stir thoroughly for 20-60 minutes to make a modified bentonite slurry with a solid content of 5%;

[0022] (2) Preparation of two-phase precursor: use ethanol to prepare titanium tetrachloride into a solution with a concentration of 2%, then add sodium oleate and water, and the amount of sodium oleate added is 4 times the molar amount of titanium tetrachloride. The volume of water is 0.5 times the volume of ethanol, adjust the pH = 5 ~ 6.5, at 20 ~ 40 o The mixture is fully stirred for 0.5 to 3 hours at a temperature of C to obtain a two-phase precursor;

[0023] (3) Mix the modified bentonite slurry prepared in step (1) with the two-phase precursor prepared in ste...

Embodiment 2

[0024] Embodiment 2, the preparation method of bentonite inorganic gel with photocatalytic properties, the preparation method consists of the following steps: (1) preparation of modified bentonite slurry: mix bentonite and surfactant in a mass ratio of 1: 10, In the stirring state, add petroleum ether or n-hexane and stir thoroughly for 20-60 minutes to make a modified bentonite slurry with a solid content of 30%;

[0025] (2) Preparation of two-phase precursor: use ethanol to prepare titanium tetrachloride into a solution with a concentration of 10%, then add sodium oleate and water, and the amount of sodium oleate added is 4 times the molar amount of titanium tetrachloride, The volume of water is 0.5 times the volume of ethanol, adjust pH=5-6.5, at 20~40 o The mixture is fully stirred for 0.5 to 3 hours at a temperature of C to obtain a two-phase precursor;

[0026] (3) Mix the modified bentonite slurry prepared in step (1) with the two-phase precursor prepared in step (2) ...

Embodiment 3

[0027] Example 3, the preparation method of bentonite inorganic gel with photocatalytic properties, the preparation method consists of the following steps: (1) Preparation of modified bentonite slurry: mix bentonite and surfactant at a mass ratio of 1:5, In the stirring state, add petroleum ether or n-hexane and stir thoroughly for 20-60 minutes to make a modified bentonite slurry with a solid content of 25%;

[0028] (2) Preparation of two-phase precursor: use ethanol to prepare titanium tetrachloride into a solution with a concentration of 6%, then add sodium oleate and water, and the amount of sodium oleate added is 4 times the molar amount of titanium tetrachloride. The volume of water is 0.5 times the volume of ethanol, adjust the pH = 5 ~ 6.5, at 20 ~ 40 o The mixture is fully stirred for 0.5 to 3 hours at a temperature of C to obtain a two-phase precursor;

[0029] (3) Mix the modified bentonite slurry prepared in step (1) with the two-phase precursor prepared in step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com