Novel method for loading silver phosphate photocatalyst on surface of cotton fabric

A surface-loaded, cotton fabric technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve the problem of not avoiding silver phosphate dust pollution, silver phosphate water dispersion Liquid instability, difficult to adapt to industrial production and other problems, to achieve the effects of excellent photocatalytic oxidation activity and reusability, easy modification of cost, strong bonding and shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

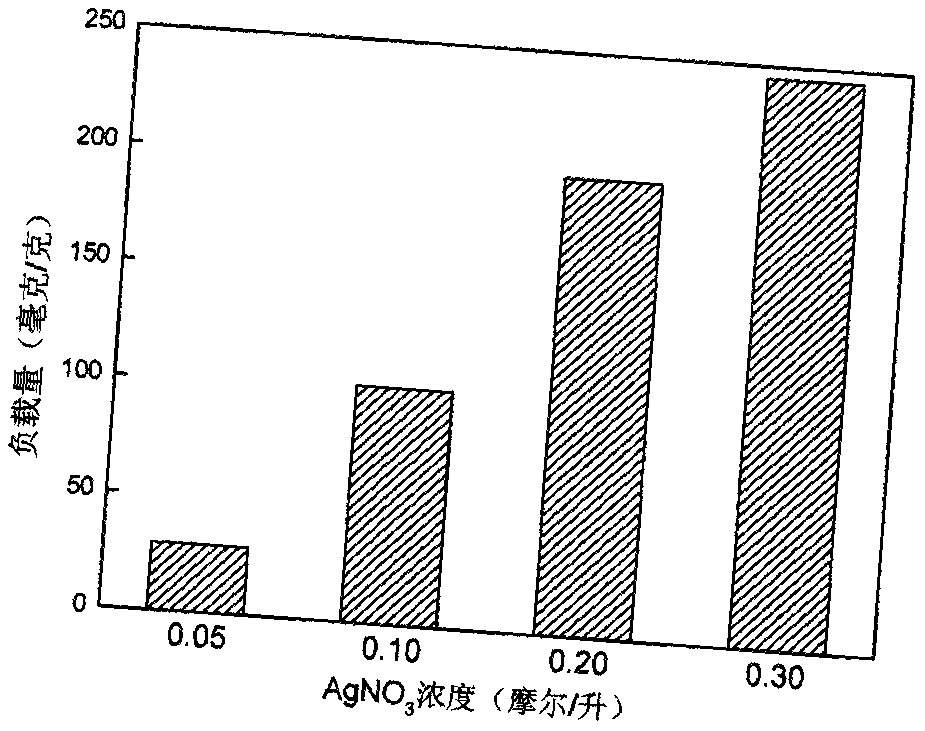

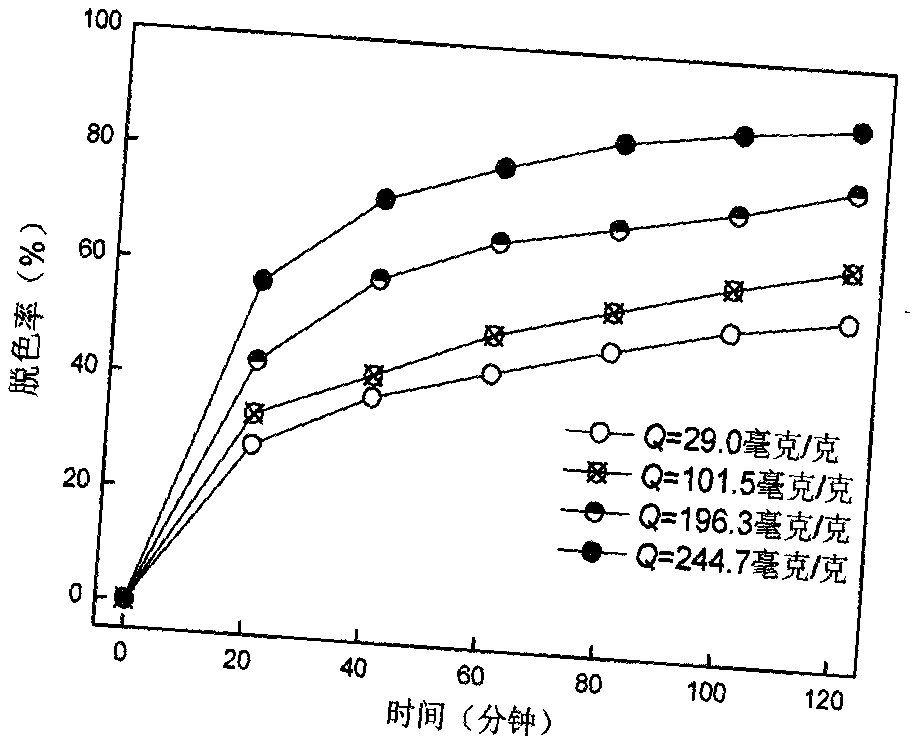

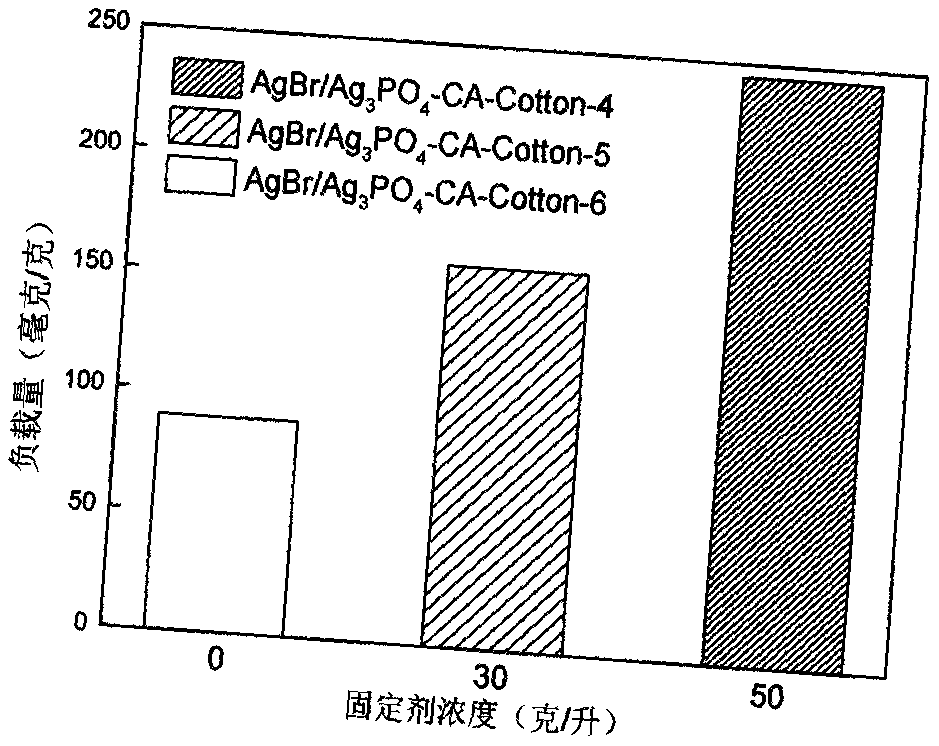

[0022]1. Loading of silver phosphate: Weigh 1.5 grams of cotton fabric and modify it with citric acid to obtain surface carboxylated cotton fabric. The obtained modified cotton fabric was immersed in an aqueous solution of silver nitrate with a concentration of 0.05 mol / liter for 15 minutes at room temperature, and the soaked fabric was dehydrated by using a uniform paddle car. Then the fabric after dehydration is immersed in the disodium hydrogen phosphate aqueous solution with concentration of 0.2 mol / liter for 15 minutes, and then the impregnated fabric is dehydrated using a uniform paddle car. The above-mentioned padding process was repeated three times, and finally the obtained fabric was dried at 60° C. to obtain a silver phosphate-loaded modified cotton fabric, and the silver phosphate load on its surface was 29.0 mg / g;

[0023] 2. Surface modification of silver bromide: Weigh 75% potassium bromide relative to the mass of silver phosphate loaded on the surface of the mo...

Embodiment 2

[0026] 1. Silver nitrate concentration is set as 0.10 mol / liter, all the other steps are with the step 1 in the embodiment 1, and the silver phosphate load on the surface of silver phosphate loaded modified cotton fabric is 101.5 mg / gram.

[0027] 2. The process is the same as step 2 in Example 1.

[0028] 3. process is identical with step 3 in embodiment 1, gained fabric is recorded as AgBr / Ag 3 PO 4 -CA-Cotton-2.

Embodiment 3

[0030] 1. silver nitrate concentration is set as 0.20 mol / liter, and all the other steps are with the step 1 in the embodiment 1, the silver phosphate load on the surface of silver phosphate load modified cotton fabric is 196.3 mg / gram.

[0031] 2. The process is the same as step 2 in Example 1.

[0032] 3. process is identical with step 3 in embodiment 1, gained fabric is recorded as AgBr / Ag 3 PO 4 -CA-Cotton-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com