High-strength splicing fireproof exhaust gas flue

A high-strength, flue gas duct technology, used in fire prevention, vertical pipes, building components, etc., can solve the problems of inconvenient handling and installation, lax closing, easy to cause fire, etc., to facilitate transportation and installation, and reduce oil pollution. , Solve the effect of smoke backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The structure of the present invention is described in detail below in conjunction with accompanying drawing:

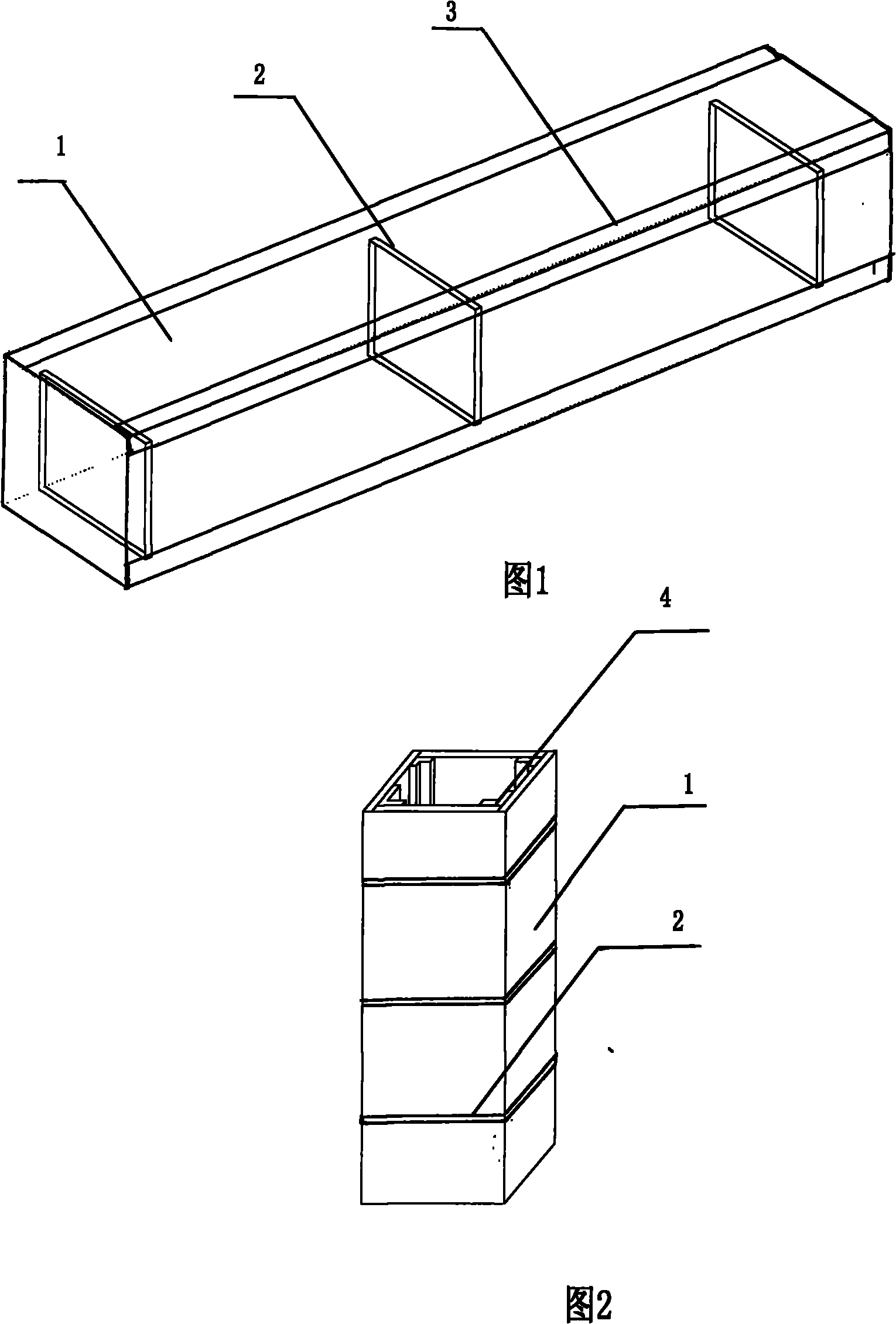

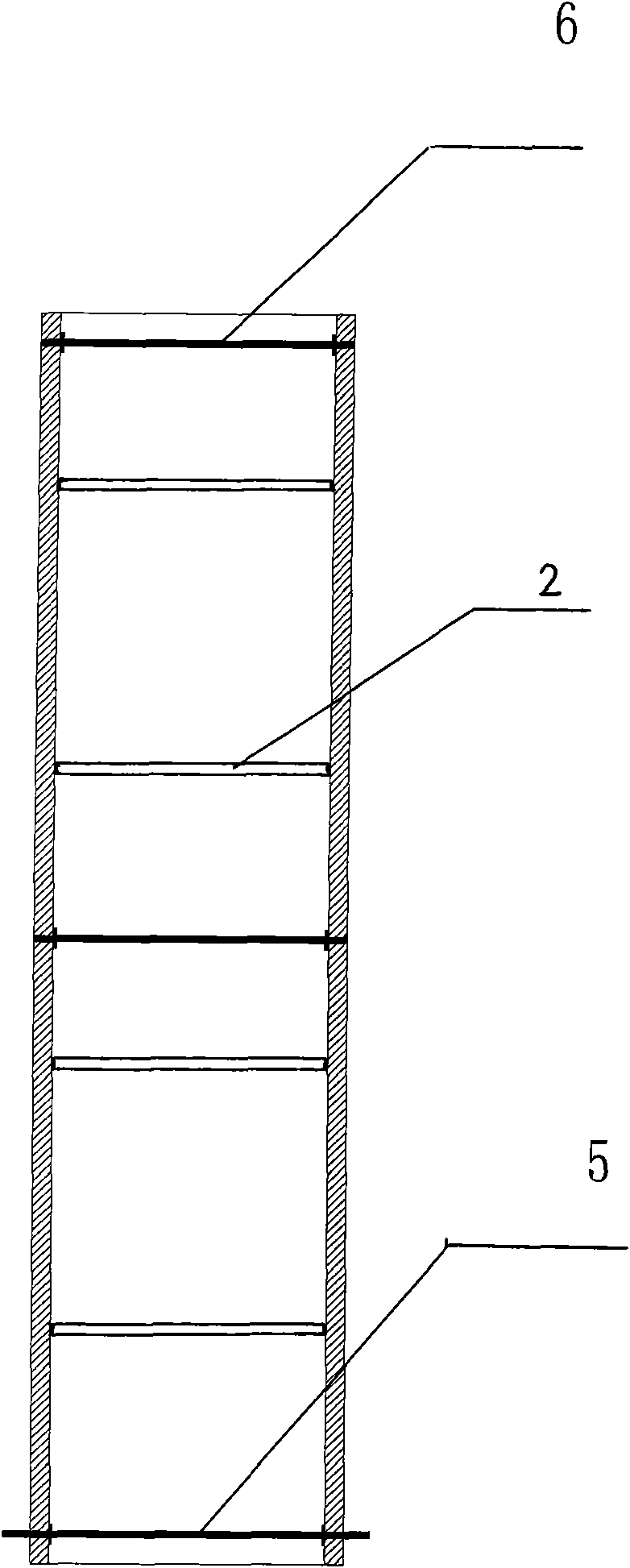

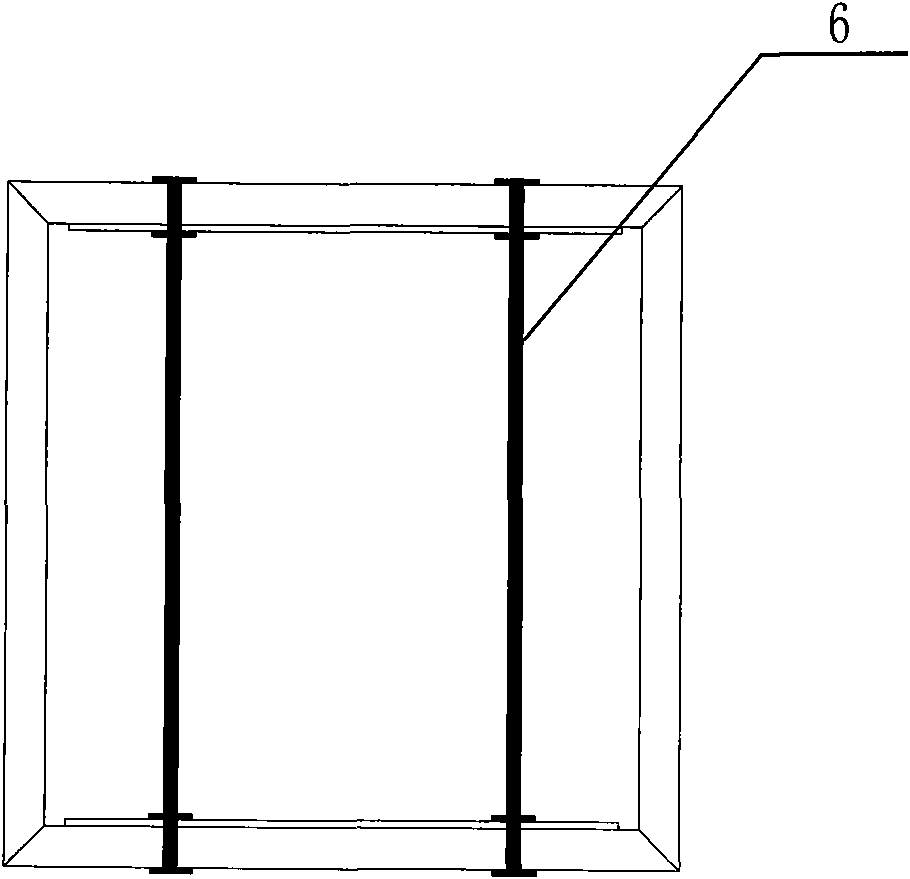

[0030] see figure 1 , the high-strength assembled fireproof smoke exhaust duct adopts high-strength fireproof boards 1 to connect and assemble to form a square channel structure (also can be rectangular or other special shapes). Inside the flue duct (such as figure 2 It can also be on the outside, or both inside and outside) from top to bottom at a distance from top to bottom and fixed with support ring 2 along the cross-sectional direction. An L-shaped reinforcing bar 3 is respectively fixed on the outside of each corner of the smoke exhaust duct, wrapping each corner respectively, and the reinforcing bar is fixed as a whole on each corner from the top to the bottom, or from the top to the bottom Multiple strips are fixed intermittently at the ends.

[0031] see figure 2 , a reinforcing rib 4 can also be set in the exhaust gas duct, and the reinforcing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com