Self-cleaning super-hydrophilic thin film and preparation method thereof

A super-hydrophilic, self-cleaning technology, applied in chemical instruments and methods, other chemical processes, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of large loss of active components, difficulties in practical processes, and difficulty in sedimentation and other problems, to achieve the effect of low equipment requirements, low production costs, and difficult recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

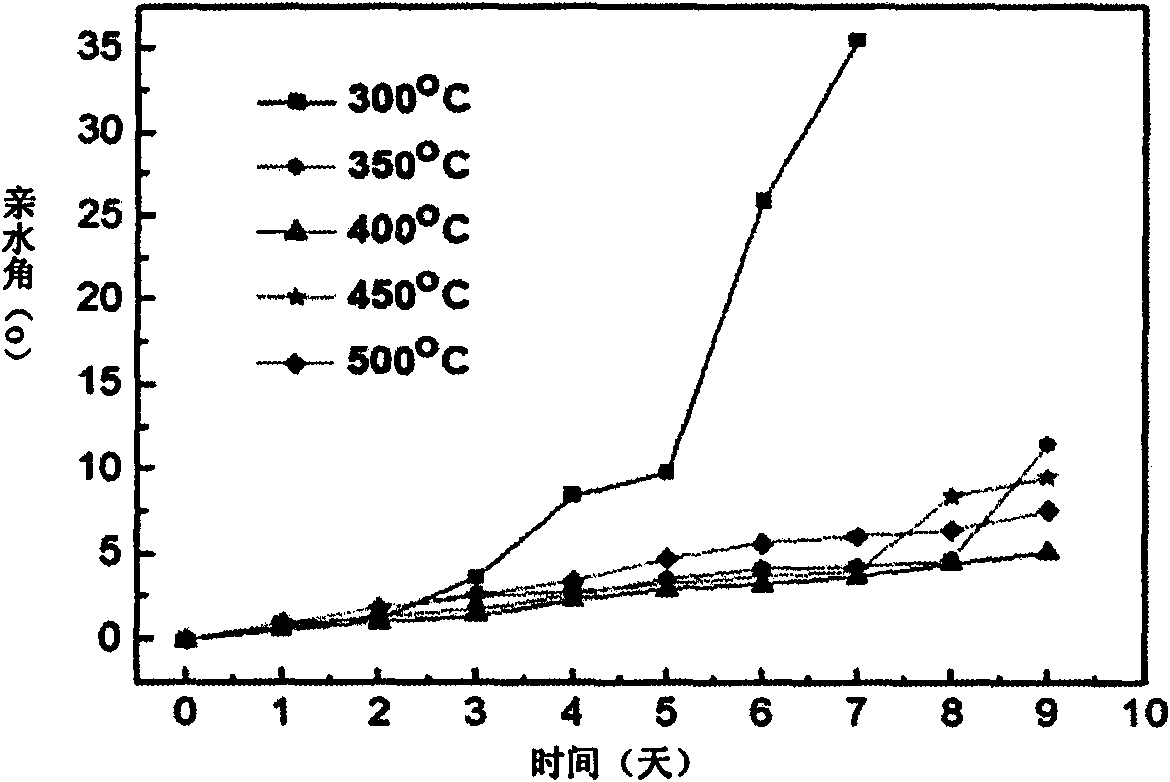

[0022] Measure 10ml of tetrabutyl titanate, add 300ml of absolute ethanol to make a solution, drop 3-4 drops of glacial acetic acid at a stirring speed of 150r / min, and magnetically stir for 30min at room temperature to fully mix the solution to obtain A solution. At the same time, another 1ml of distilled water and 200ml of absolute ethanol were added, and the mass ratio of tetrabutyl titanate was 0.5% La(NO 3 ) 3 ·6H 2 O, magnetically stirred for 30min to obtain B solution. Slowly add the obtained B solution to A solution, add hydrochloric acid to adjust the pH to 3, and stir for 30 minutes to obtain stable, uniform, clear and transparent TiO 2 Sol. Preparation of Rare Earth Doped Nano TiO by Impregnation-Pull Method Using Self-made Film Pulling Machine 2 film. Dip the pretreated substrate into the prepared sol, and pull the coating after the glass sheet and the liquid level are stable. After coating a layer of film, dry at 50-100°C for 5-10min and cool at room temper...

Embodiment 2

[0024] Measure 20ml of tetrabutyl titanate, add 300ml of absolute ethanol to make a solution, drop 3-4 drops of glacial acetic acid at a stirring speed of 150r / min, and magnetically stir for 30min at room temperature to fully mix the solution to obtain A solution. At the same time, another 1ml of distilled water and 200ml of absolute ethanol were added, and the mass ratio of tetrabutyl titanate was 0.5% La(NO 3 ) 3 ·6H 2 O and 0.05% Fe(NO 3 ) 3 9H 2 O, magnetically stirred for 30min to obtain B solution. Slowly add the obtained B solution into A solution, add hydrochloric acid to adjust the pH to 4, and stir for 30 minutes to obtain stable, uniform, clear and transparent TiO 2 Sol. Preparation of Rare Earth Doped Nano TiO by Impregnation-Pull Method Using Self-made Film Pulling Machine 2 film. Dip the pretreated substrate into the prepared sol, and pull the coating film at a certain speed after the glass sheet and the liquid level are stable. After coating a layer of...

Embodiment 3

[0026] Measure 10ml of tetrabutyl titanate, add 300ml of absolute ethanol to make a solution, drop 3-4 drops of glacial acetic acid at a stirring speed of 150r / min, and magnetically stir for 30min at room temperature to fully mix the solution to obtain A solution. At the same time, another 1ml of distilled water and 200ml of absolute ethanol were taken, and the mass ratio of tetrabutyl titanate was 0.1-1.0% Ce(NO 3 ) 3 ·6H 2 O, magnetically stirred for 30min to obtain B solution. Slowly add the obtained B solution into A solution, add hydrochloric acid to adjust the pH to 5, and stir for 30 minutes to obtain stable, uniform, clear and transparent TiO 2 Sol. Preparation of Rare Earth Doped Nano TiO by Impregnation-Pull Method Using Self-made Film Pulling Machine 2 film. Dip the pretreated substrate into the prepared sol, and pull the coating after the glass sheet and the liquid level are stable. After coating a layer of film, dry at 50-100°C for 5-10min and cool at room ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com