Method for preparing organic-inorganic nano-composite membranes by using layered inorganic nano particles

An inorganic nano and composite membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of easy reassembly or agglomeration of nanosheets, achieve convenient operation, simple equipment, and overcome easy agglomeration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

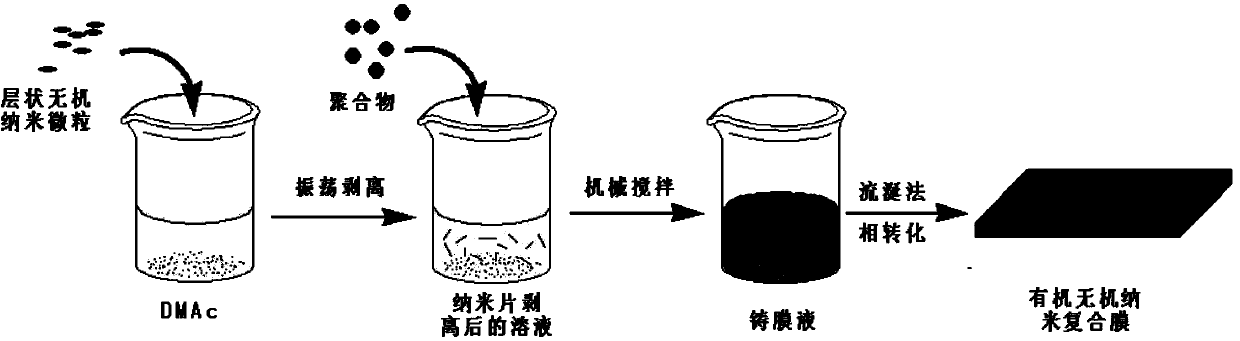

[0029] Step 1: Preparation and in situ exfoliation of highly crystalline Zn / Al carbonate hydrotalcite

[0030] 0.20 mol of ZnSO 4 ·7H 2 O, 0.05 mol of Al 2 (SO 4 ) 3 18H 2 Add O into 135mL deionized water and stir well to dissolve to form a salt solution. Another weighed 20.90 g NaOH and 17.20 g NaOH 2 CO 3 Dissolve in 135 mL deionized water to form an alkaline solution. Mix the above two solutions well and slowly add them dropwise into 108 mL of deionized water, adjust the pH to 10, then reflux for 8 h for crystallization, filter with suction after the reaction, fully dry at 60°C, and grind into a powder for future use. use.

[0031] Disperse 0.5 g of the prepared Zn / Al hydrotalcite in 0.75 mol NaNO 3 and 0.0025 mol HNO 3 500 mL of aqueous solution, in N 2 Protect the reaction at room temperature with magnetic stirring (or shaking) for one day. After the reaction, centrifuge to remove the supernatant, wash with deionized water several times, and dry in vacuum.

...

Embodiment 2

[0037] The first step: the preparation of high crystallinity Zn / Al carbonate hydrotalcite and the steps and methods of ion intercalation exchange are as in Example 1.

[0038] 0.022 g NO 3 - The exchanged Zn / Al hydrotalcite was dispersed in 77 g DMAc, in N 2 Shake the reaction (170 rpm) for 1 day under protection, and centrifuge to remove the unexfoliated hydrotalcite to obtain a DMAc colloidal solution of Zn / Al hydrotalcite nanosheets.

[0039] Step 2: Preparation of exfoliated Zn / Al hydrotalcite nanosheets / polyethersulfone nanofiltration membrane

[0040] The formulation of the casting solution is: 22g of PES (polyethersulfone); 1g of PVP (polyvinylpyrrolidone, Mn=24000); 77g of DMAc colloidal solution of Zn / Al hydrotalcite nanosheets.

[0041] Add PVP and PES respectively to the DMAc colloidal solution of Zn / Al hydrotalcite nanosheets under constant mechanical stirring, stir well for 12 hours to fully dissolve them, and form a uniform and transparent casting solution. Fil...

Embodiment 3

[0043] The first step: the preparation of high crystallinity Zn / Al carbonate hydrotalcite and the steps and methods of ion intercalation exchange are as in Example 1.

[0044] 0.044 g NO 3 - The exchanged Zn / Al hydrotalcite was dispersed in 77 g DMAc, in N 2 Shake the reaction (170 rpm) for 1 day under protection, and centrifuge to remove the unexfoliated hydrotalcite to obtain a DMAc colloidal solution of Zn / Al hydrotalcite nanosheets.

[0045] Step 2: Preparation of exfoliated Zn / Al hydrotalcite nanosheets / polyethersulfone nanofiltration membrane

[0046] Steps and methods are as in Example 2.

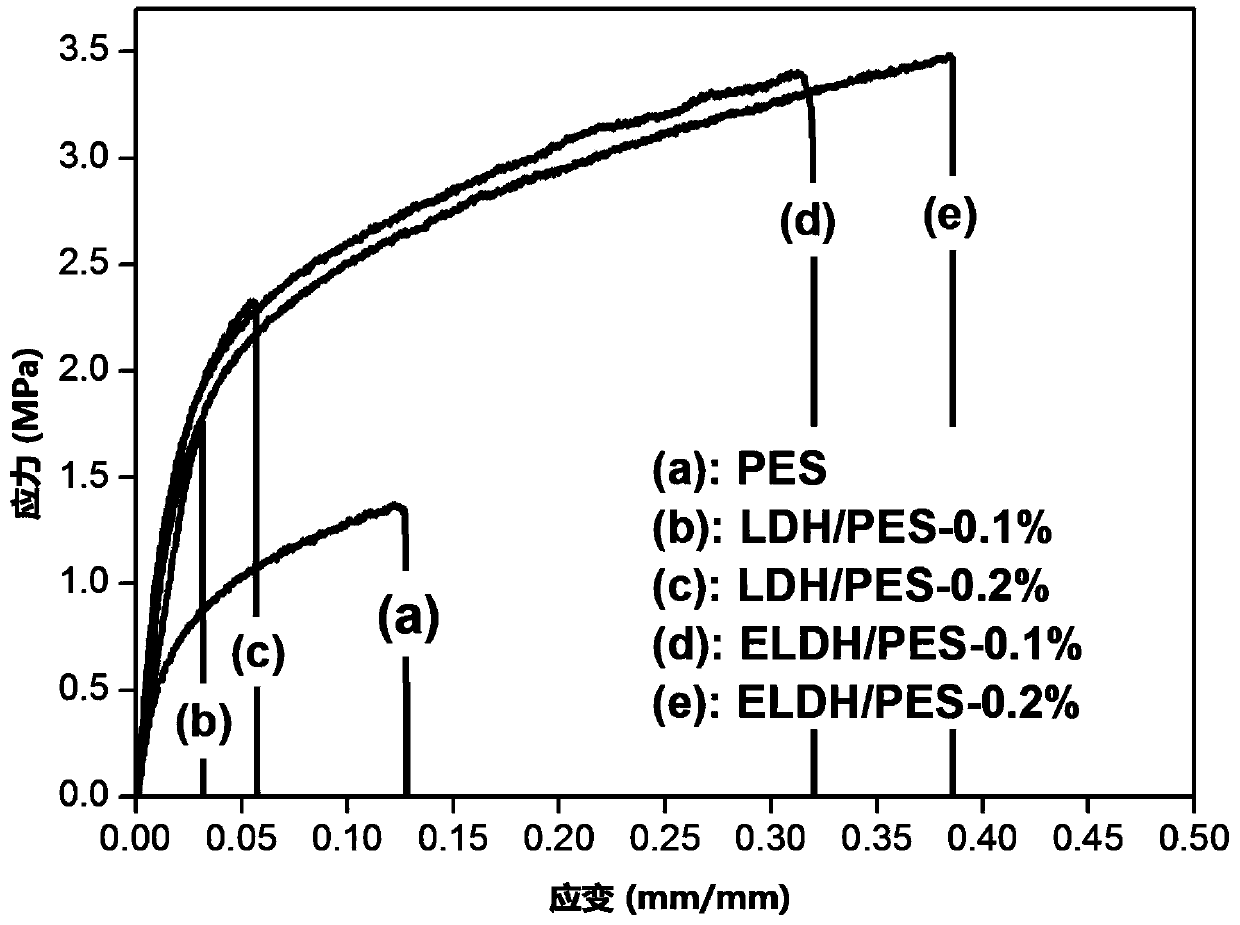

[0047] Mechanical properties of the obtained Zn / Al hydrotalcite nanosheets / polyethersulfone hybrid nanofiltration membrane:

[0048] The mechanical properties of the hybrid film were tested by UTM2203 electronic universal tester (Jinan Huike Testing Equipment Co., Ltd.). The stretching rate is 5mm / min, and the stretching sensor is 100N.

[0049] In order to illustrate the super...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com