Surface fluorine-doped polymer fiber and preparation method thereof

A polymer and surface doping technology, applied in the field of fiber materials, can solve problems such as increased complexity, and achieve the effects of universality, strong applicability, and novel and simple technical solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

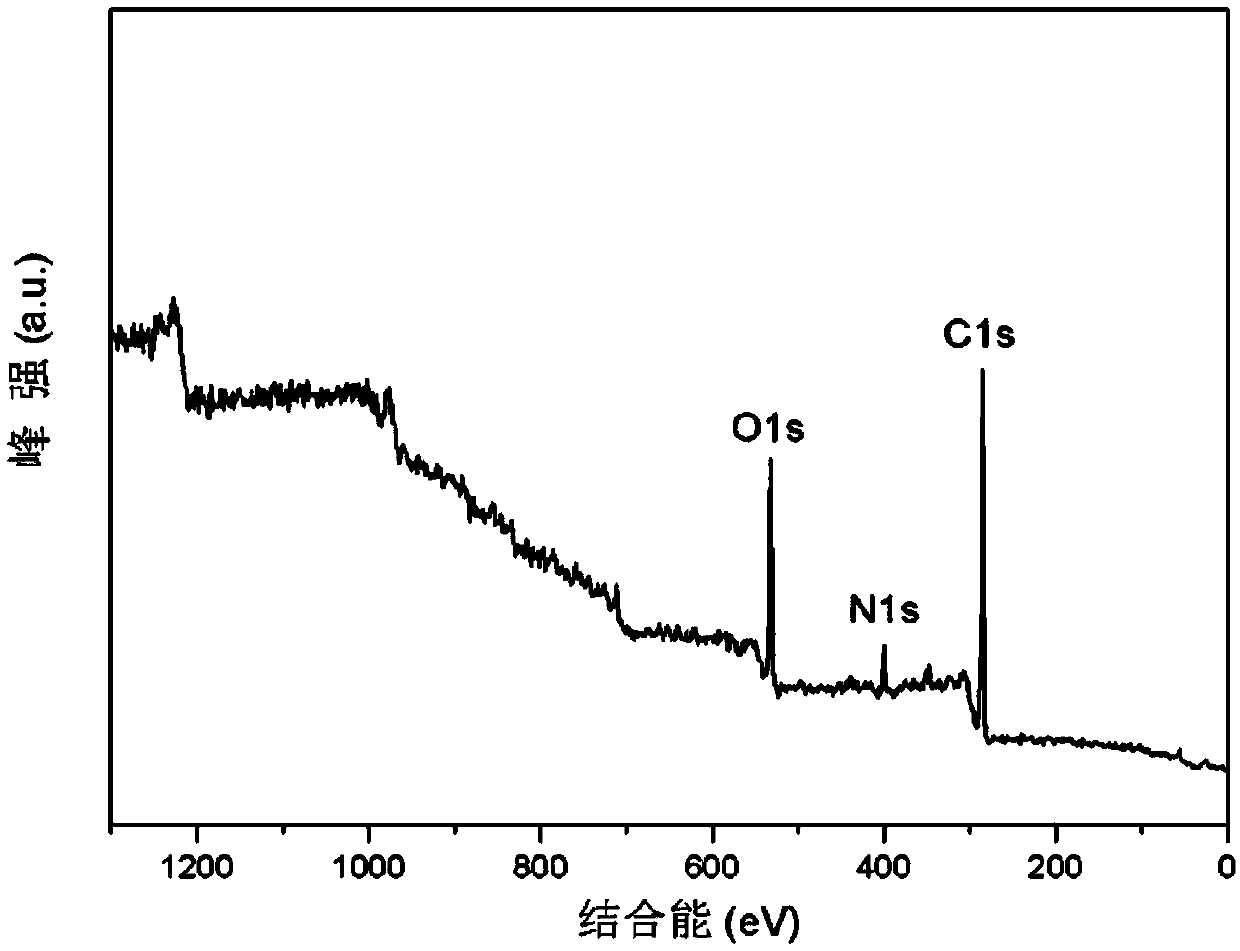

[0034] Using polyacrylonitrile as the raw material and N,N-dimethylformamide (DMF) as the solvent, the spinning stock solution was prepared according to the conventional ratio, and electrospinning was carried out, and a flat-woven 35-mesh stainless steel metal mesh was used as the receiving device to obtain Bulk polyacrylonitrile nanofibers.

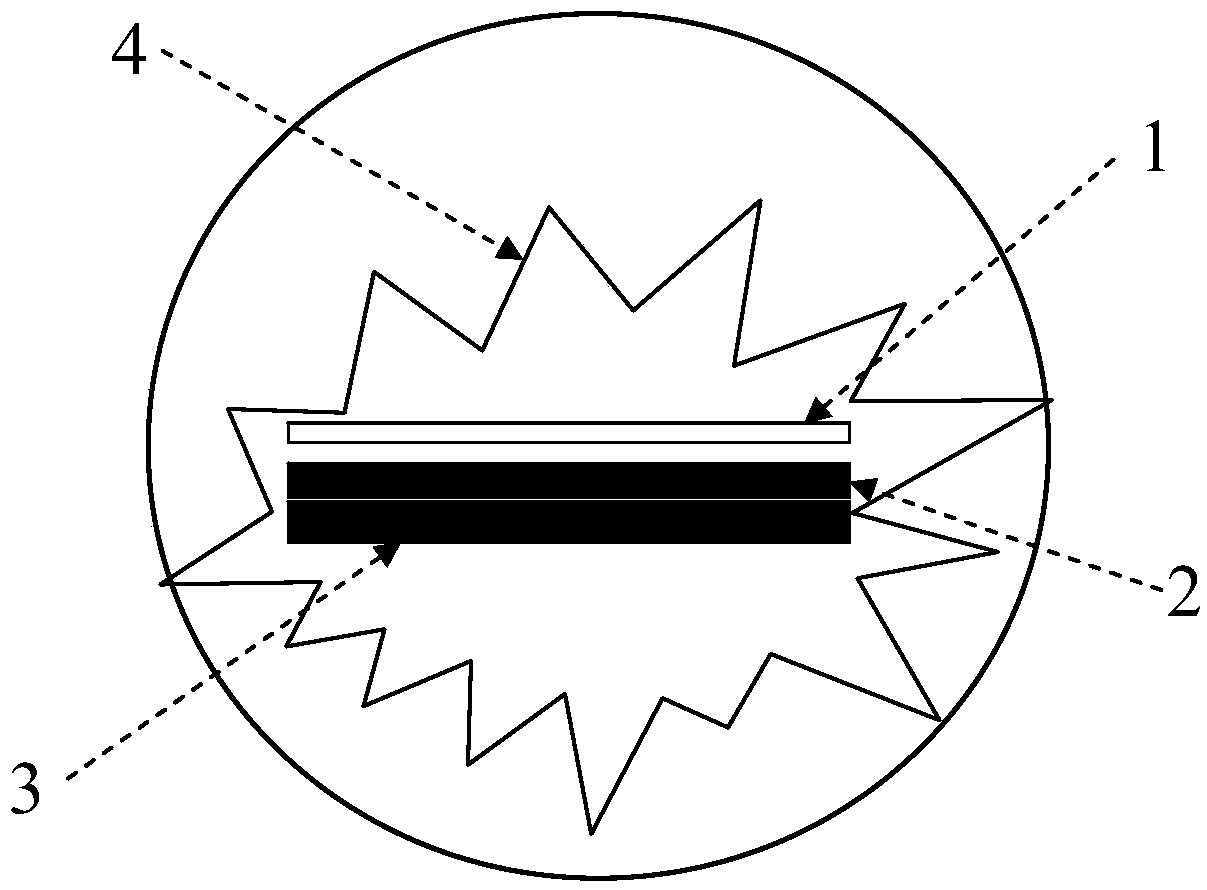

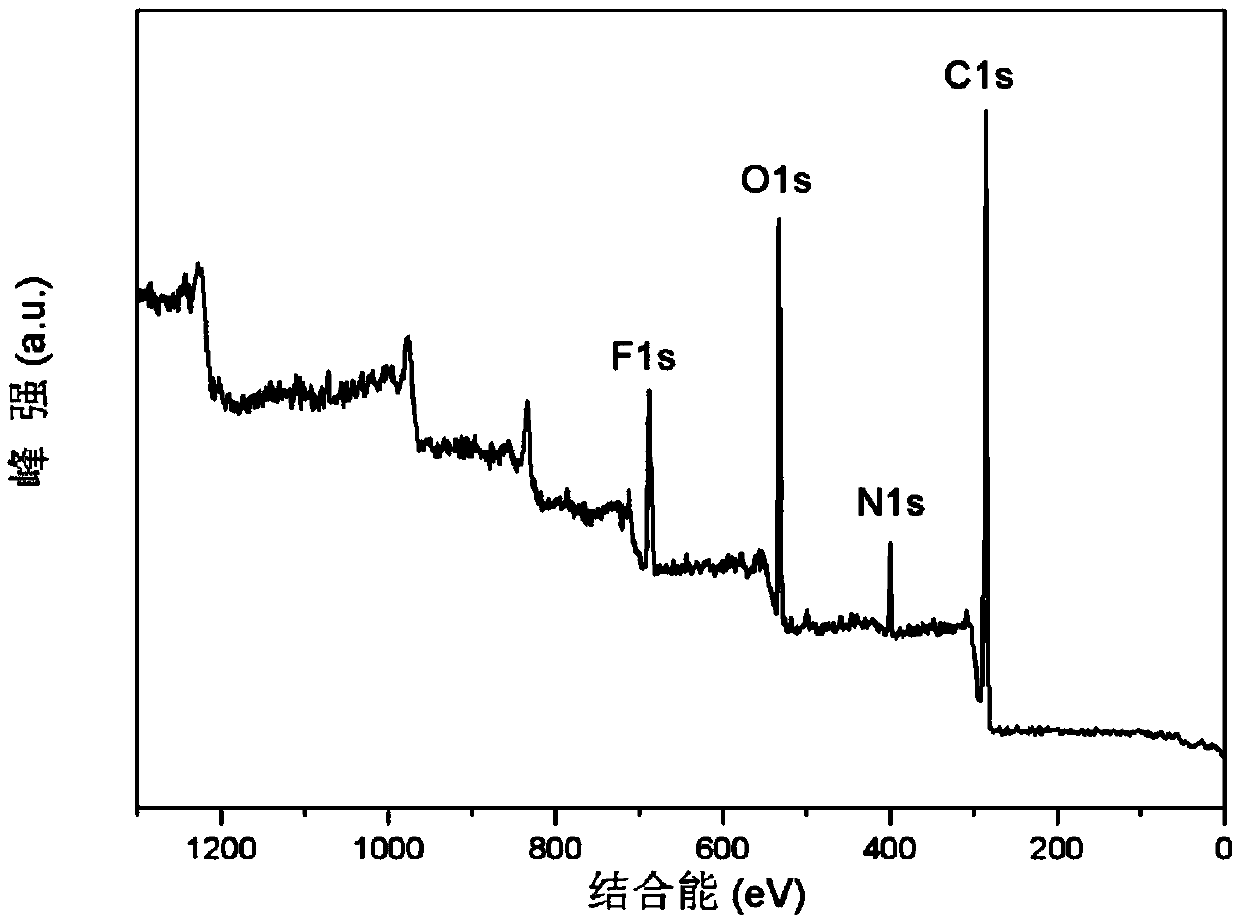

[0035] see figure 1, place the metal mesh 1 loaded with nanofibers on the top of a polytetrafluoroethylene film 2 of the same size and a thickness of 1 mm, keep the distance between the two at 0.5 mm, and place the polytetrafluoroethylene film in a plasma generator on electrode 3. Subsequently, the AC power was turned on, and under the condition of 10Pa, argon was used as the discharge gas to uniformly glow discharge to generate glow plasma 4, and the treatment was performed at a power of 50W for 60s to prepare polyacrylonitrile nanofibers doped with fluorine on the surface. The invention utilizes the metal mesh and the plasma generati...

Embodiment 2

[0038] Using polyvinylpyrrolidone as the raw material and deionized water as the solvent, the spinning stock solution was prepared according to the conventional ratio, and electrospinning was performed, and the flat-woven 50-mesh nickel metal mesh was used as the receiving device to obtain bulk polyvinylpyrrolidone nanofibers. Place the metal mesh loaded with bulk nanofibers on top of a polytetrafluoroethylene film of the same size and thickness of 2.5 mm, keep the distance between the two at 0.3 mm, and place it on the plasma generating electrode. Then, turn on the radio frequency power supply, under the condition of 30Pa, use helium as the discharge gas to generate a uniform glow discharge, and treat it under the power of 20W for 300s, that is, the polymer nanofibers doped with fluorine on the surface are prepared. After calculation and analysis, the proportion of fluorine element to the total elements is 35%.

Embodiment 3

[0040] Using polyamide as the raw material and formic acid as the solvent, the spinning stock solution was prepared according to the conventional ratio, and electrospinning was carried out, and the plain-woven 20-mesh copper metal mesh was used as the receiving device to obtain bulk polyamide nanofibers. The metal mesh loaded with bulk nanofibers was placed on a polytetrafluoroethylene film of the same size and a thickness of 2 mm, keeping the distance between the two at 1 mm, and placed on the plasma generating electrode. Subsequently, the DC power supply was turned on, and under the condition of 100Pa, nitrogen gas was used as the discharge gas to generate a uniform glow discharge, and the treatment was performed at a power of 80W for 180s, and the polymer nanofibers doped with fluorine on the surface were prepared. After calculation and analysis, the proportion of fluorine element to the total elements is 12%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com