Self-humidification membrane electrode for proton exchange membrane fuel cell and preparation method thereof

A proton exchange membrane, fuel cell technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of inability to achieve high-performance self-humidification/non-humidification, low temperature adaptation range, and achieve excellent self-humidification performance , Improve moisturizing performance, increase the effect of anti-diffusion power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

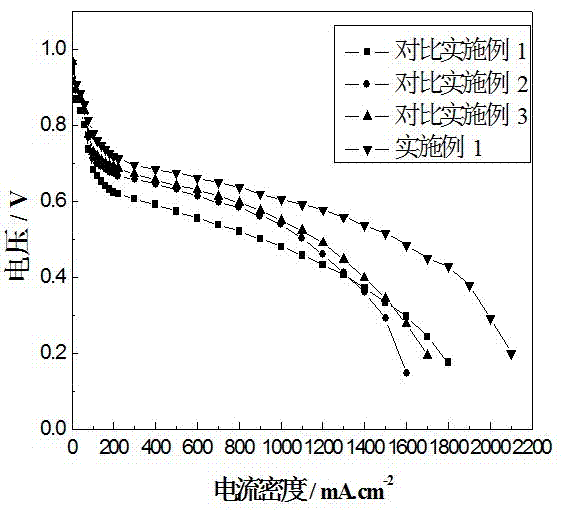

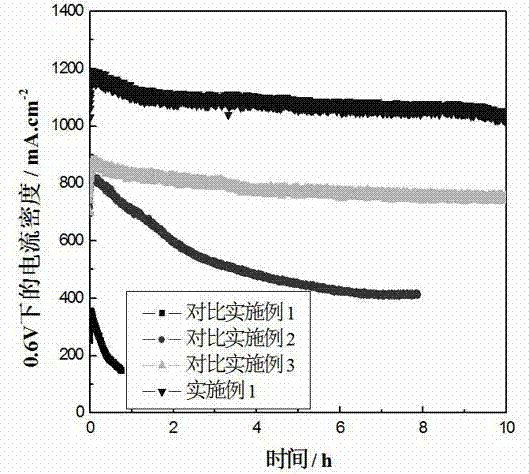

Embodiment 1

[0041] The first step is to take 4cm × 4cm NAFION212 proton exchange membrane. First place it in 80 ° C for 1 hour in the hydrogen percentage of 5%percentage concentration. After distilled water washing, at 0.5 mol.l, -1 Treat it at 80 ° C in the sulfate solution for 1 hour, and then wash it with distilled water.The processed proton exchange membrane is placed on the fixed framework of the preparation film electrode, and the size of the active area is 5cm 2 To prevent the membrane from shrinking and deformation during the process of spraying catalyst slurry;

[0042] In the second step, take 1g of polyvinyl alcohol (PVA) to dissolve into 99g of ionic water, and the water solution with a PVA with a mass of 1%is made;

[0043] The third step takes 1g of gas phase silica to scattered in 1L ofopenol, and the quality concentration is 1g.L. -1 The isopropanol suspension liquid of the silicon dioxide;

[0044] Step 4 Press 10: 4: 0.1: 0.1: 500 The mass ratio is called a PT / C catalyst (Hi...

Embodiment 2

[0068] In addition to changing the NAFION 212 film to Nafion 117 membrane, a polyethylene alcohol solution with a mass of 1%to 1%to a beeflytic acid solution with a shell polycan with a mass of 1 ‰, 1g.L -1 The alcohol suspension of the gas phase silicon dioxide was changed to 1g.L -1 The alcohol of titanium pink is divided into turbidity liquid, and the PT / C catalyst (Hispec 4100, Johnson Matthey) with a PT content of 40%in the fourth step is changed to a PT / C catalyst with a PT content of 20%(E-TEKCompany) Outside, and press 10: 2.5: 0.1: 0.1: 300 ratios, which are called PT / C catalysts with a 6.2mg content of 20%, 31.3mg general fluorine sulfonic acid resin solution (5WT% NaFion, Dupont), 78.9mg No. 1The quality percentage concentration in the two -step preparation is the acetic acid solution of the shell with 1 ‰, the titanium pink isopropyl amoid alcohol suspension in the third step of 28 μl, and the 0.2 g ofopenol.The preparation method of membrane electrode is the same as E...

Embodiment 3

[0072] In addition to changing a polyethylene alcohol solution with a mass of 1%to a polyethylene pyrirol (PVP) solution with a mass percentage concentration of 1 ‰, 1 G.L will be 1g.L -1 The alcohol suspension of the gas phase silicon dioxide was changed to 1g.L -1 Jiekou SIO 2 (MCM-41) The isopropanol suspension solution, the PT / C catalyst (Hispec 4100, Johnson Matthey) with a PT content of 40%in the fourth step is to 1: 1: 1: PTRU atomic ratio with a total PTRU content of 40%is 1:1 PTRU / C catalysts, as well as 10: 3: 0.1: 0.1: 500 ratio, respectively, which are called PT / C catalysts (E-TEK) with a 3.1mg content of 20%, respectively5WT%NaFion, Dupont), 41mg of ethanol solution with PVP with a mass of 1 ‰, and 1g.L of 25 μL -1 The alcohol suspension and 0.2 g ofopenol of the silicon dioxide, the remaining steps are the same as the embodiment 1, the preparation method of the membrane electrode is the same as the embodiment 1.

[0073] Except for the mass ratio of 10: 4: 0.1: 500, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com