Method for preparing nano-Pd or Pd platinum alloy electrocatalyst for fuel cell

A technology of electrocatalyst and fuel cell, which is applied in the direction of catalyst activation/preparation, battery electrodes, chemical instruments and methods, etc. It can solve the problems of poor performance of oxygen electrodes and achieve the effects of easy operation, good application prospects and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

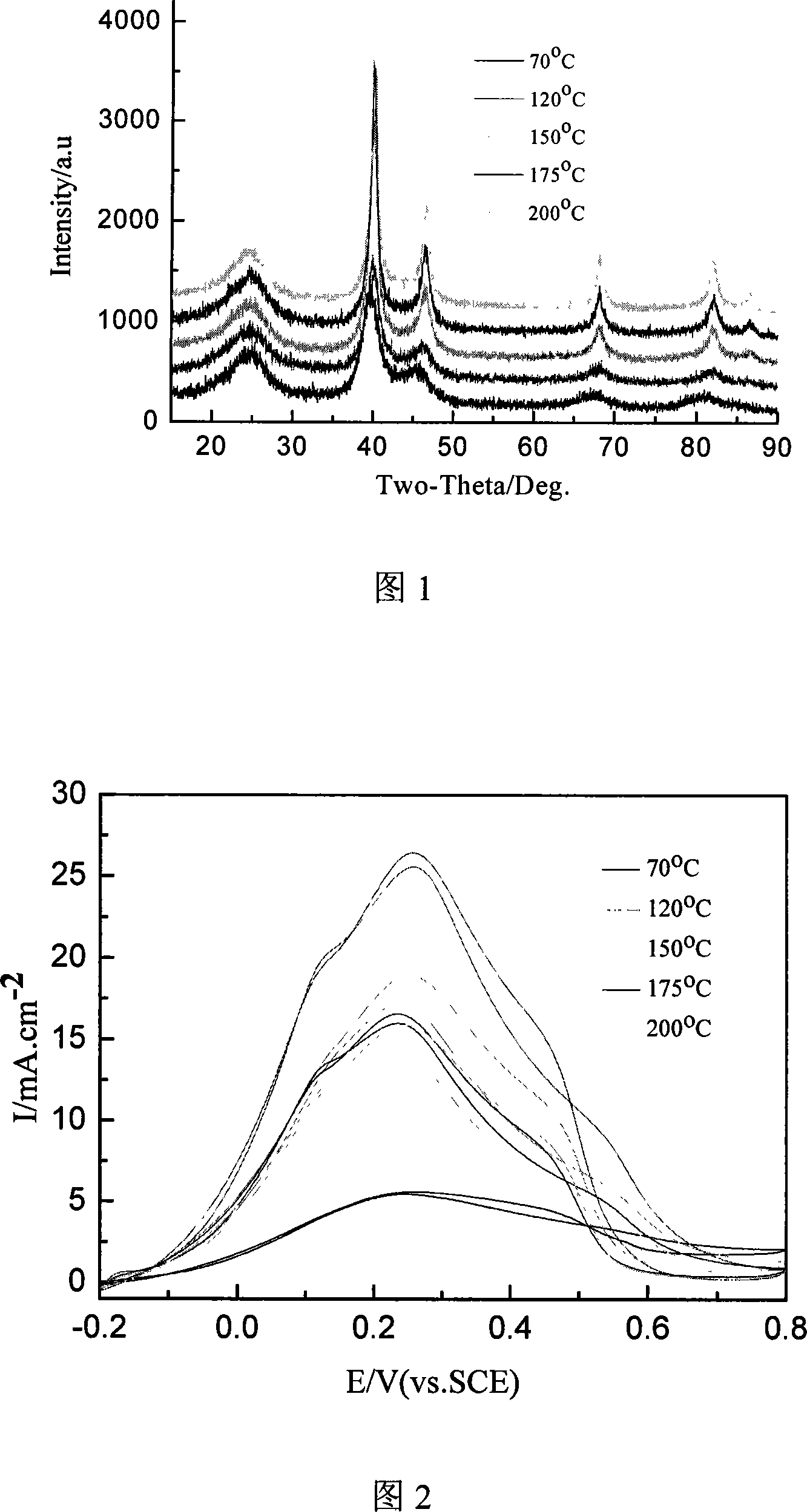

[0020] The preparation of embodiment 1, Pd / C (20wt.%) catalyst

[0021] 1. Weigh 50mg of PdCl 2 (metal palladium content 59.98%), it is dissolved in the water of 13ml and stirs to dissolve, and the amount of adding the same substance is 2.8ml concentration and is the EDTA solution of 0.1mol / L, is warming up to 60 ℃ and constant temperature stirring 40min, and the solution changes from brown to Bright yellow, then continue to stir and cool to room temperature (component A).

[0022] 2. Add NaOH solution with a concentration of 1.0mol / L dropwise to the cooled solution, adjust the pH to 9~10, add 120mg of XC-72 carbon, ultrasonicate for 30min, and stir for 1.5h to disperse evenly (component B).

[0023] 3. Slowly add 8ml of NaBH with a concentration of 4.5mg / ml dropwise under the condition of stirring 4 Solution, and continue to stir for 1h, then filter, wash with deionized water and ultrapure water in turn, until no chloride ion can be detected by silver nitrate. Then, the ca...

Embodiment 2

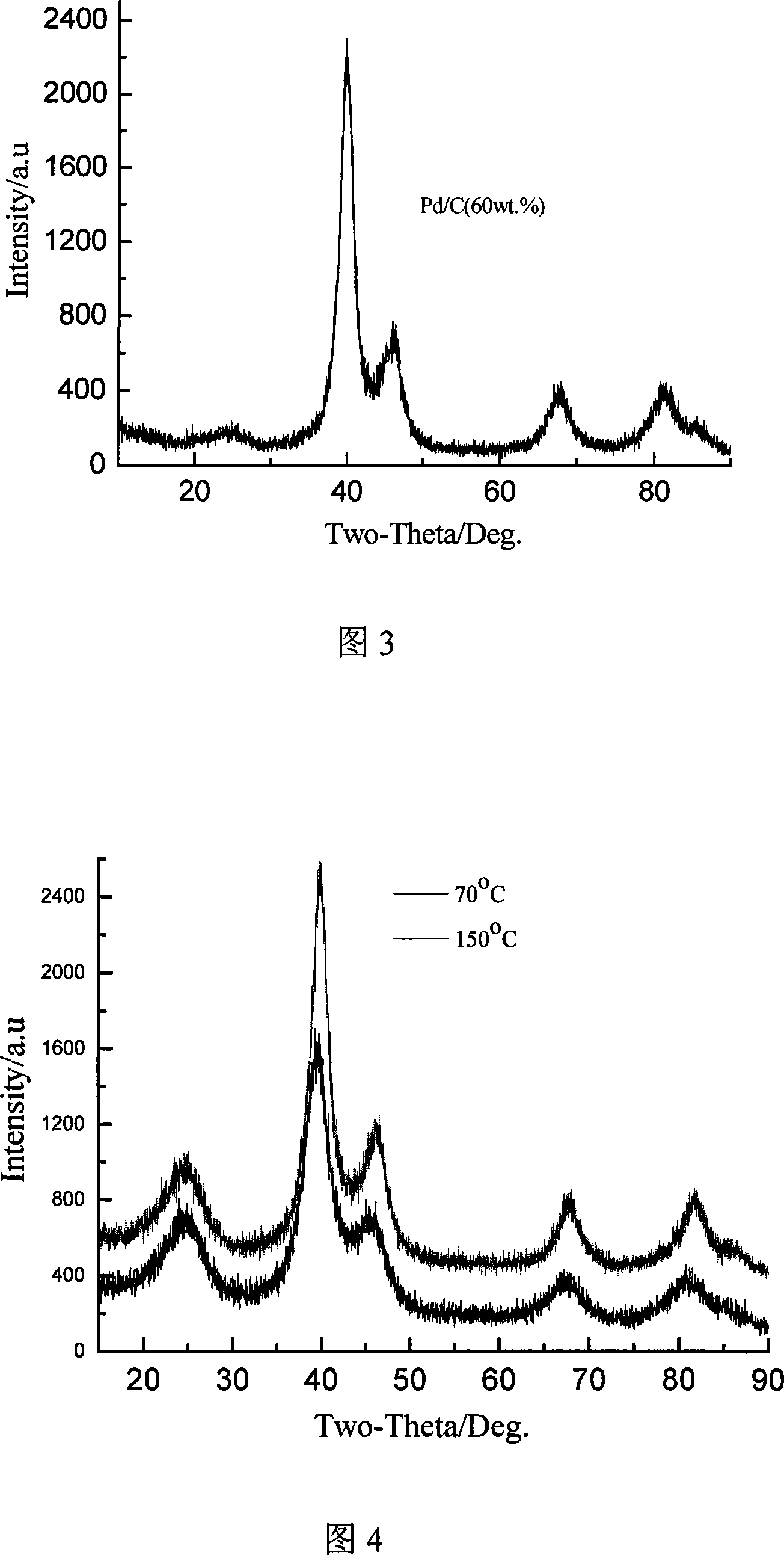

[0026] The preparation of embodiment 2, Pd / C (60wt.%) catalyst

[0027] 1. Weigh 90mg of PdCl 2 (metal palladium content 59.98%), it is dissolved in the water of 10ml and stirs to dissolve, and adding 1.1ml concentration is the DTPA solution of 0.5mol / L, is warming up to 60 ℃ and constant temperature stirring 40min, and solution turns bright yellow by brown, then continues Stir and cool to room temperature (Component A).

[0028] 2. Add NaOH solution with a concentration of 1.0mol / L dropwise to the cooled solution, adjust the pH to 9-10, add 36mg of XC-72 carbon, ultrasonicate for 30min, and stir for 1.5h to disperse evenly (component B).

[0029] 3. Slowly add 10ml of NaBH with a concentration of 5.0mg / ml dropwise under the condition of stirring 4 solution (reducing agent required in theory is 9.6mg, get 5 times the amount), and continue to stir for 1h, then filter, wash with deionized water until there is no chloride ion, during which the aqueous solution of silver nitrate...

Embodiment 3

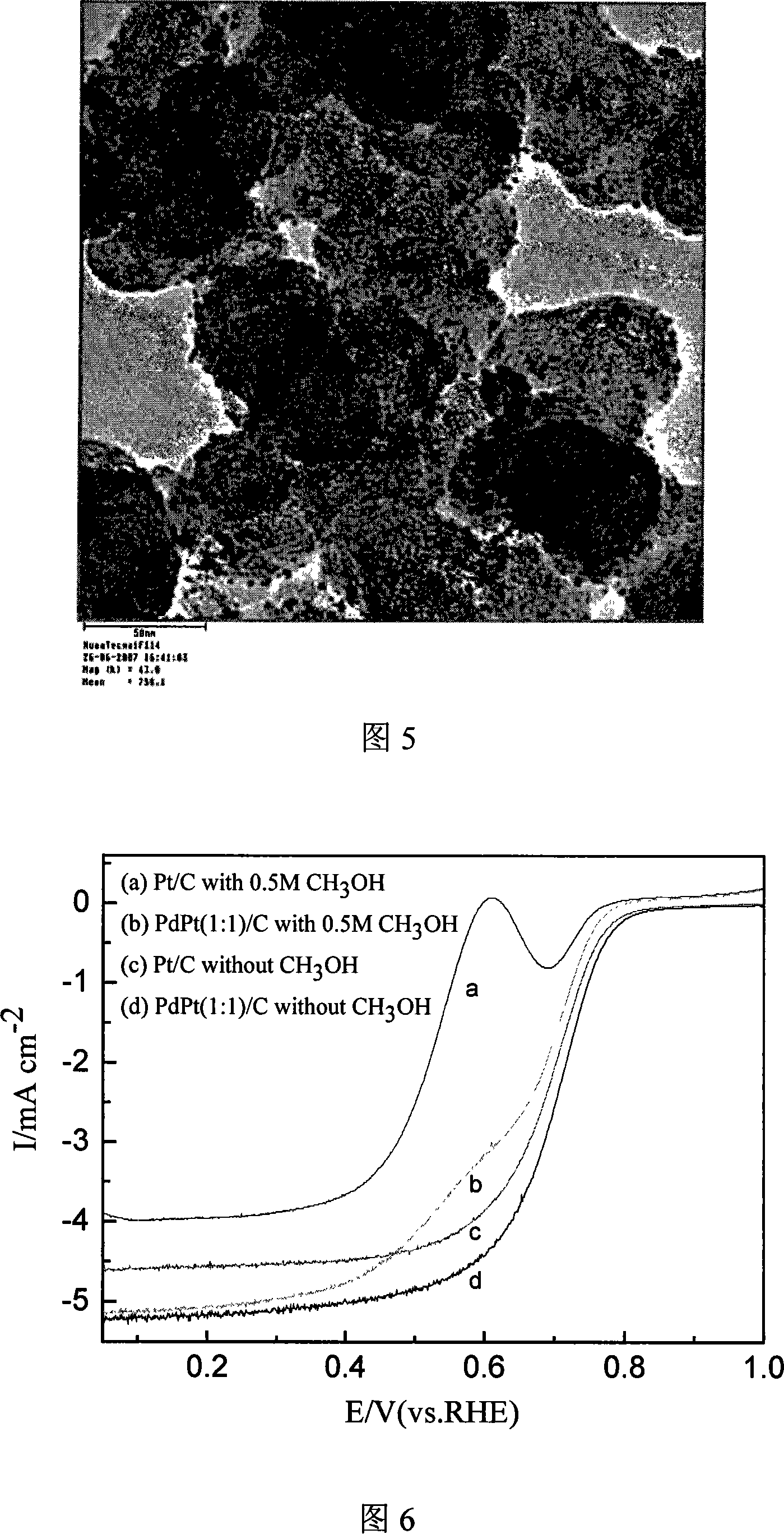

[0032] Embodiment 3, the preparation of PdPt (1: 1, 20wt.%) / C catalyst

[0033] 1. Weigh 25mg of PdCl 2 (metal palladium content 59.98%), it is dissolved in the water of 5ml and stirs to dissolve, and the Na of 79.2mg is weighed in addition 2 PtCl 6 ·6H 2 O was dissolved in 5ml of water, then the two solutions were mixed and stirred, 5.6ml of EDTA solution with a concentration of 0.05mol / L was added, the temperature was raised to 60°C and stirred at constant temperature for 40min, and then continued to stir and cooled to room temperature (component A).

[0034] 2. Add dropwise NaOH solution with a concentration of 1.0mol / L to the cooled solution, adjust the pH to 9~10, add 171.7mg of XC-72 carbon, ultrasonicate for 30min, and then stir for 1.5h to disperse evenly (component B) .

[0035] 3. Slowly add 12ml of NaBH with a concentration of 4.67mg / ml dropwise under the condition of stirring 4 solution, and continue to stir for 1h, then filter, wash with deionized water until...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com