Modified aluminium-magnesium alloy fuel cell

A fuel cell and magnesium alloy technology, applied in battery electrodes, fuel cell half-cells, primary battery half-cells, circuits, etc., can solve battery voltage, efficiency battery output power loss, fuel cell practical application limitations, Hydrogen fuel use safety hazards and other issues, to achieve the effect of long power supply time, easy acquisition, and improved conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following examples are further explanations and illustrations of the present invention, and do not constitute any limitation to the present invention.

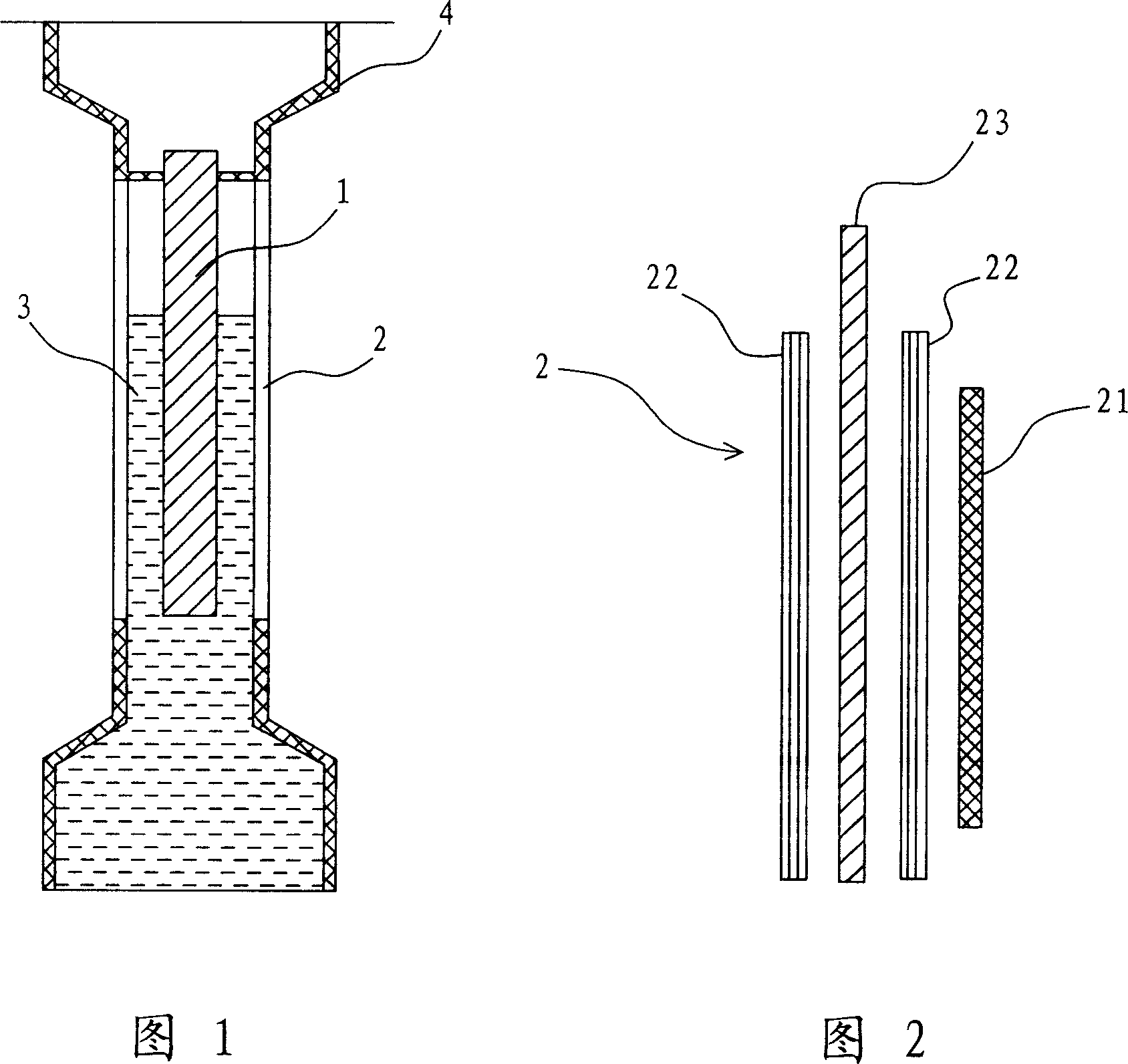

[0026] Referring to Fig. 1, modified aluminum of the present invention, magnesium alloy fuel cell have an airtight rectangular plastic case 4, and metal anode 1, negative electrode 2 and electrolytic solution 3 are housed in case 4, and described metal anode 1 is modified The modified aluminum and magnesium alloy anode contains no less than 60% magnesium. The modified magnesium metal electrode has active chemical properties and can release a large amount of electrons stably and continuously. The negative electrode 2 is an air electrode, and the air electrode 2 is made of an anode catalytic electrode 21, a waterproof gas-permeable membrane 22 and a silver-plated conductive copper wire mesh 23, wherein the anode catalytic electrode 21 is made of activated carbon, manganese dioxide, graphite , silicon oxide mixture, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com