Copper electrolyte extracting and purifying process technology

A purification process and copper electrolyte technology, applied in the field of smelting, can solve the problems of no better copper electrolyte purification method, affecting the quality of electrolytic copper and current efficiency, etc., and achieve the effect of good quality, reasonable configuration and high current efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

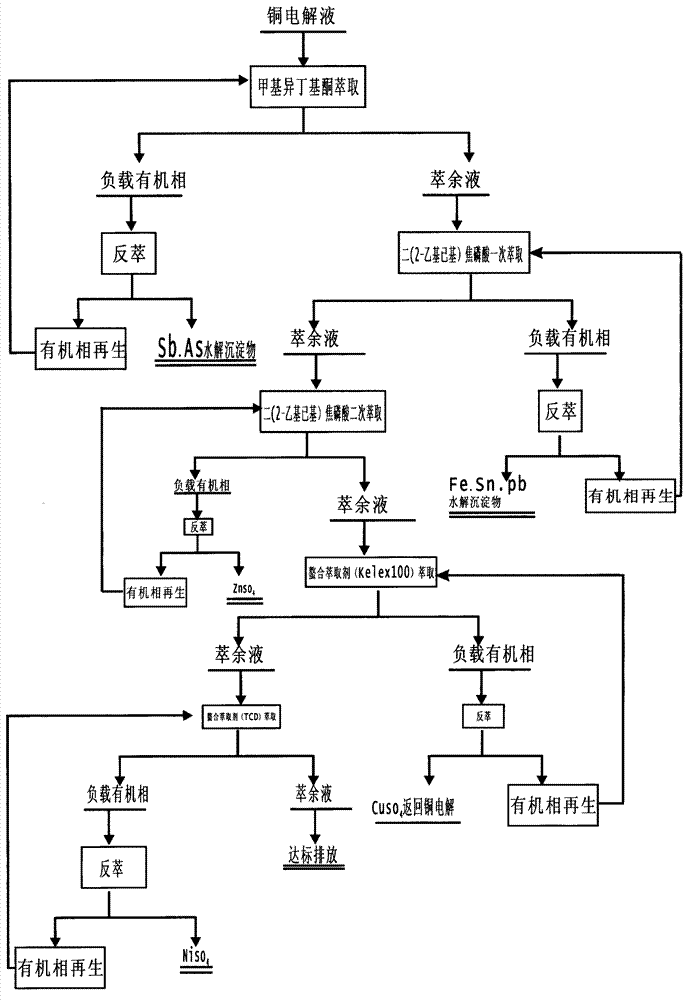

Image

Examples

Embodiment 1

[0020] Example 1: The copper electrolyte is directly extracted with methyl isobutyl ketone without any treatment, and the obtained loaded organic phase is back-extracted with water to obtain the hydrolysis precipitate of antimony and arsenic, and the organic phase is returned to methyl isobutyl ketone after regeneration extraction. The raffinate obtained by methyl isobutyl ketone extraction is once extracted with two (2-ethylhexyl) pyrophosphoric acid, and the loaded organic phase is back-extracted with water to obtain the hydrolysis precipitate of iron, tin and lead, and the organic phase is regenerated and returned to two ( 2-Ethylhexyl)pyrophosphoric acid once extracted, bis(2-ethylhexyl)pyrophosphoric acid extracted once, and the raffinate was adjusted to pH between 2.5 and 4.0, and bis(2-ethylhexyl)pyrophosphoric acid was extracted twice , the obtained loaded organic phase is back-extracted with water to obtain a zinc sulfate solution, and the organic phase is regenerated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com