Arrangement method for anode unit for electrolysis

A layout method and anode technology, applied in electrolysis components, electrodes, electrolysis process, etc., can solve the problems of unsatisfactory, small feed rate of milling ear, increase of production cost, etc., so as to reduce production cost, prolong the life of milling cutter, reduce Effect of small milling forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

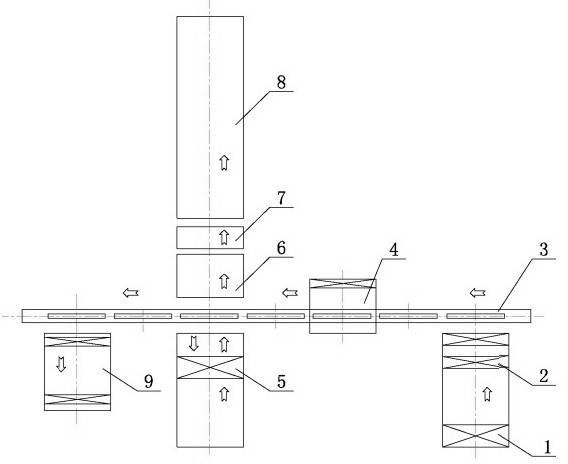

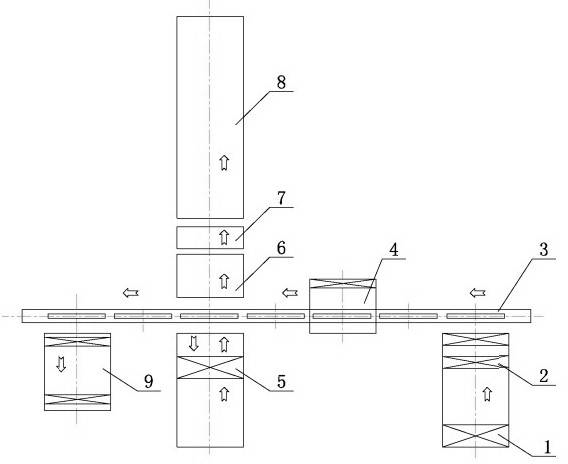

[0011] A method for arranging an anode unit for electrolysis, the equipment of the method includes a plate receiving device 1 capable of receiving anodes, a plate receiving chain transport machine and slices, vertical straightening ears, a weighing mechanism 2, a traverse device 3, and a plate surface Shaping press and thickness measuring device 4, side milling ear device 5, bottom milling ear device 6, inclined lifting device 7, plate chain conveyor and plate rack 8 and waste plate removal equipment 9; the traverse device 3 The side milling lug device 5 is arranged on one side of the head, and the bottom milling lug device 6 is arranged on the other side; in this way, the anode plate without the side milling lug is directly sent to the Enter the bottom milling ear position for bottom milling ear; the anode plate that needs side milling ear is sent to the side milling ear position for side milling ear, after the side milling ear is completed, it is sent to the bottom milling ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com