Recovery treatment method for waste phosphoric acid

A technology of recycling and acid pretreatment, applied in chemical instruments and methods, phosphorus compounds, electrolytic components, etc., can solve the problems of poor applicability of phosphoric acid and the inability to use phosphoric acid directly, achieving low cost, realizing resource utilization, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

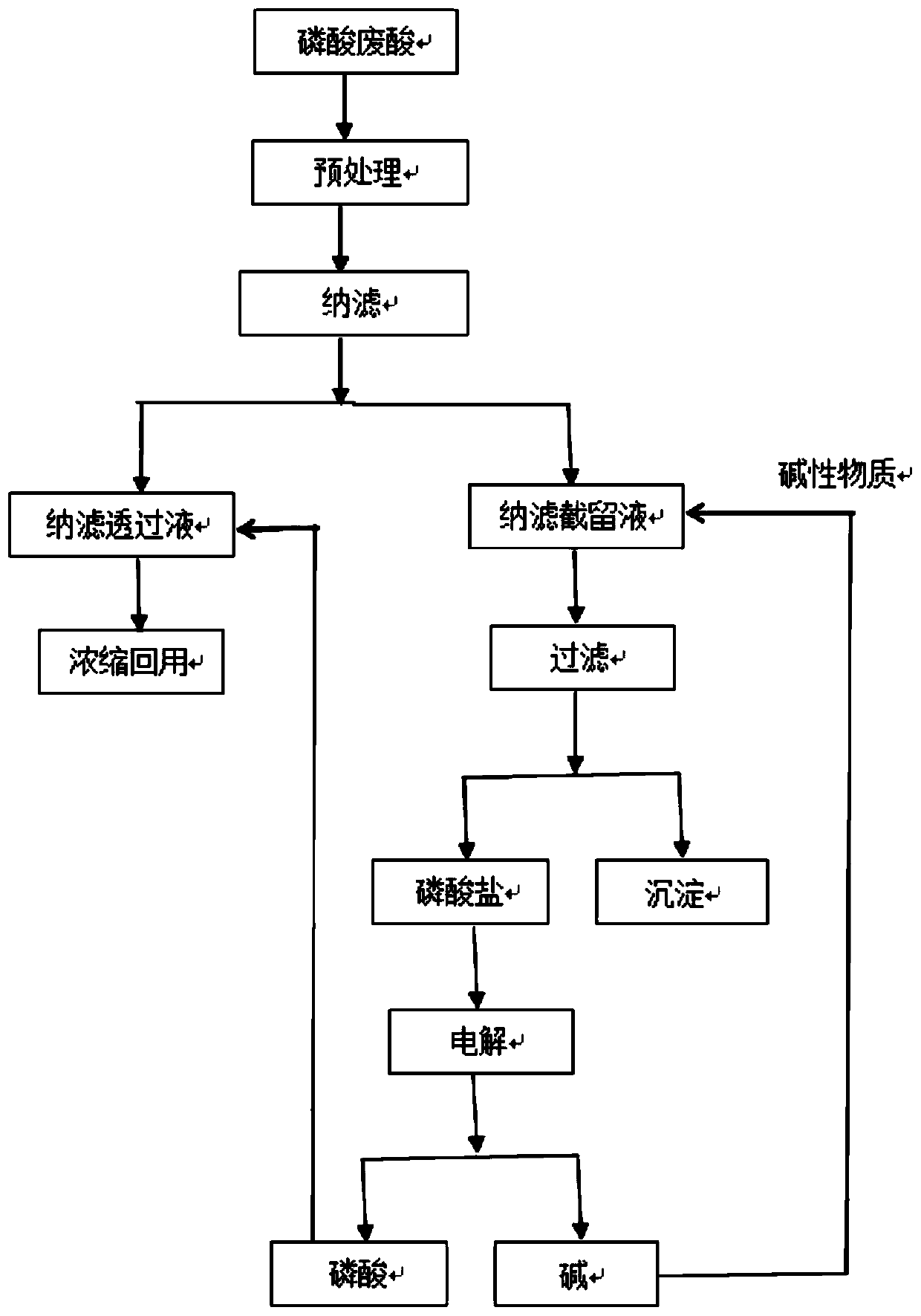

[0052] This embodiment provides a method for recycling waste phosphoric acid, the process flow chart of the method is as follows figure 1 shown, including the following steps:

[0053] (1) Phosphoric acid waste acid is first subjected to ultrafiltration pretreatment, and then nanofiltration treatment, the composition of phosphoric acid waste acid includes phosphoric acid and Al 3+ , Ca 2+ , Mg 2+ Inorganic metal ions, the mass fraction of phosphoric acid in phosphoric acid waste acid is 50wt%, the pressure of the nanofiltration treatment is 3.5MPa, and the temperature is 30°C to obtain the nanofiltration permeate and the nanofiltration retentate; the nanofiltration permeate The main composition of the liquid includes phosphoric acid, and the nanofiltration permeate is subjected to evaporation and concentration treatment until the concentration reaches 82wt%;

[0054] (2) adding sodium hydroxide to the nanofiltration retentate obtained in step (1) to remove impurities, the a...

Embodiment 2

[0058] This embodiment provides a method for recycling waste phosphoric acid, the method comprising the following steps:

[0059] (1) Phosphoric acid waste acid is first subjected to ultrafiltration pretreatment, and then nanofiltration treatment, the composition of phosphoric acid waste acid includes phosphoric acid and Al 3+ , Ca 2+ , Mg 2+ Inorganic metal ions, the mass fraction of phosphoric acid in phosphoric acid waste acid is 70wt%, the pressure of the nanofiltration treatment is 2MPa, and the temperature is 35°C to obtain the nanofiltration permeate and the nanofiltration retentate; the nanofiltration permeate The main components include phosphoric acid, and the nanofiltration permeate is subjected to evaporation and concentration treatment until the concentration reaches 85wt%;

[0060] (2) adding potassium hydroxide to the nanofiltration retentate obtained in step (1) for impurity removal, the addition of the potassium hydroxide is sufficient to adjust the pH value...

Embodiment 3

[0064] This embodiment provides a method for recycling waste phosphoric acid, the method comprising the following steps:

[0065] (1) Phosphoric acid waste acid is first subjected to ultrafiltration pretreatment, and then nanofiltration treatment, the composition of phosphoric acid waste acid includes phosphoric acid and Al 3+ , Ca 2+ , Mg 2+ Inorganic metal ions, the mass fraction of phosphoric acid in phosphoric acid waste acid is 20wt%, the pressure of the nanofiltration treatment is 5MPa, and the temperature is 25°C to obtain the nanofiltration permeate and the nanofiltration retentate; the nanofiltration permeate The main components include phosphoric acid, and the nanofiltration permeate is subjected to evaporation and concentration treatment until the concentration reaches 80wt%;

[0066] (2) adding sodium hydroxide to the nanofiltration retentate obtained in step (1) for impurity removal, the addition of the sodium hydroxide satisfies the adjustment pH value of 9, af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com