Electrolytic additive formula for improving zinc sulfate solution electrolyzed zinc quality and production environment and application method

A technology of zinc sulfate solution and production environment, which is applied in the direction of electrolysis process, electrolysis components, process efficiency improvement, etc. It can solve the problems of high lead and iron content, poor quality of electrolytic zinc in zinc sulfate solution, and low recovery rate of ingots. Achieve the effects of reducing lead content, improving the quality and production environment of electrolytic zinc in zinc sulfate solution, and improving the electrolytic environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

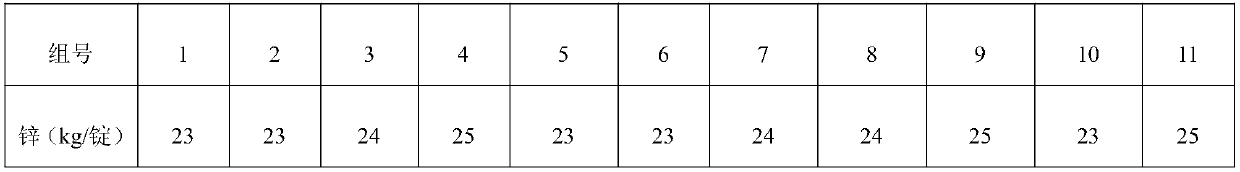

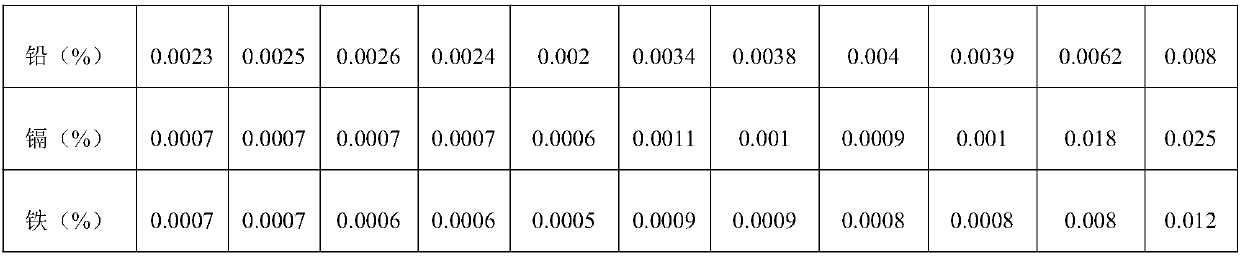

Embodiment 1

[0028] This embodiment provides a method for improving the quality of electrolytic zinc in zinc sulfate solution and the use of electrolytic additives in the production environment, including:

[0029] Adopt zinc sulfate solution as electrolyte, wherein, electrolyte comprises new liquid and waste liquid; Wherein, the acid concentration of new liquid is 165g / L, the zinc concentration of new liquid is 52g / L; The acid concentration of waste liquid is 168g / L , the zinc concentration of the waste liquid is 50g / L; the lead-silver alloy plate is used as the anode plate, the rolled aluminum plate is used as the cathode plate, and the current density during electrolysis is controlled to be 380A / m 2 , the temperature during electrolysis is controlled to be 36°C;

[0030]When the density of zinc on the rolled aluminum plate decreases, add bone glue solution 2kg / cycle to the electrolyte; prepare polyacrylamide solution with polyacrylamide, polyethylene glycol, and sodium methylene dinapht...

Embodiment 2

[0032] This embodiment provides a method for improving the quality of electrolytic zinc in zinc sulfate solution and the use of electrolytic additives in the production environment, including:

[0033] Adopt zinc sulfate solution as electrolyte, wherein, electrolyte comprises new liquid and waste liquid; Wherein, the acid concentration of new liquid is 165g / L, the zinc concentration of new liquid is 52g / L; The acid concentration of waste liquid is 168g / L , the zinc concentration of the waste liquid is 50g / L; the lead-silver alloy plate is used as the anode plate, the rolled aluminum plate is used as the cathode plate, and the current density during electrolysis is controlled to be 380A / m 2 , the temperature during electrolysis is controlled to be 36°C;

[0034] When the density of zinc on the rolled aluminum plate decreases, add bone glue solution 3kg / cycle to the electrolyte; prepare polyacrylamide solution with polyacrylamide, polyethylene glycol, and sodium methylene dinaph...

Embodiment 3

[0036] This embodiment provides a method for improving the quality of electrolytic zinc in zinc sulfate solution and the use of electrolytic additives in the production environment, including:

[0037] Adopt zinc sulfate solution as electrolyte, wherein, electrolyte comprises new liquid and waste liquid; Wherein, the acid concentration of new liquid is 165g / L, the zinc concentration of new liquid is 52g / L; The acid concentration of waste liquid is 168g / L , the zinc concentration of the waste liquid is 50g / L; the lead-silver alloy plate is used as the anode plate, the rolled aluminum plate is used as the cathode plate, and the current density during electrolysis is controlled to be 380A / m 2 , the temperature during electrolysis is controlled to be 36°C;

[0038] When the density of zinc on the rolled aluminum plate decreases, add bone glue solution 2.5kg / cycle to the electrolyte; polyacrylamide, polyethylene glycol, and sodium methylene dinaphthalene sulfonate are formulated in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com