Method for removing magnesium via cycle of ethanol in electrolytic manganese machining process

A processing technology, electrolytic manganese technology, applied in photography technology, electrolysis process, electrolysis components, etc., can solve problems such as ion diffusion hindrance, conductivity drop, complex process, etc., achieve simple and easy electrolysis operation, improve product quality, improve The effect of the electrolytic environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

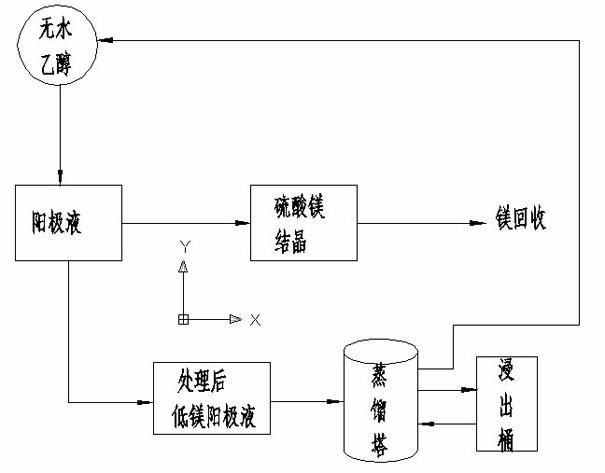

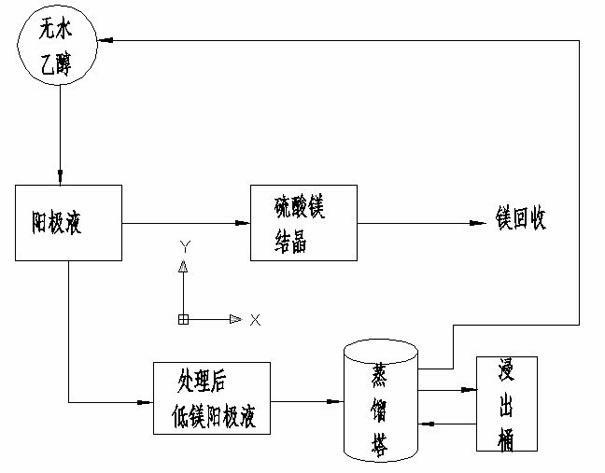

[0015] like figure 1 Among them, in the electrolytic manganese processing technology of the present invention, the ethanol circulation method for removing magnesium is to introduce absolute ethanol in the existing electrolytic manganese process flow, and its addition is 80-125g / l: that is, add anhydrous ethanol to the anolyte of electrolytic manganese Ethanol, stir or fully stir to make it evenly mixed, and adjust the temperature at about 35-55°C, the optimum temperature is at about 45°C, so that a large amount of magnesium sulfate in the anolyte can be salted out and precipitated; then filter the anolyte to remove impurities, that is Remove the magnesium sulfate precipitate in the anolyte, and the removal rate of magnesium sulfate can reach more than 75%; then the filtered solution is distilled and separated from the ethanol, so as to realize the recovery and recycling of the separated ethanol, and at the same time, it is not sent to the anode Other substances are added to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com