Printing and dyeing airing device

A technology of drying device and drying rod, which is applied in the direction of processing textile material equipment configuration, liquid/gas/steam removal by air jet method, and processing textile material carrier, etc., which can solve the problem that printing and dyeing and drying cannot be carried out at the same time, and the drying rack for printing and dyeing is inconvenient to adjust , Poor stability of drying racks, etc., to reduce the printing and dyeing procedures, increase optional types, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

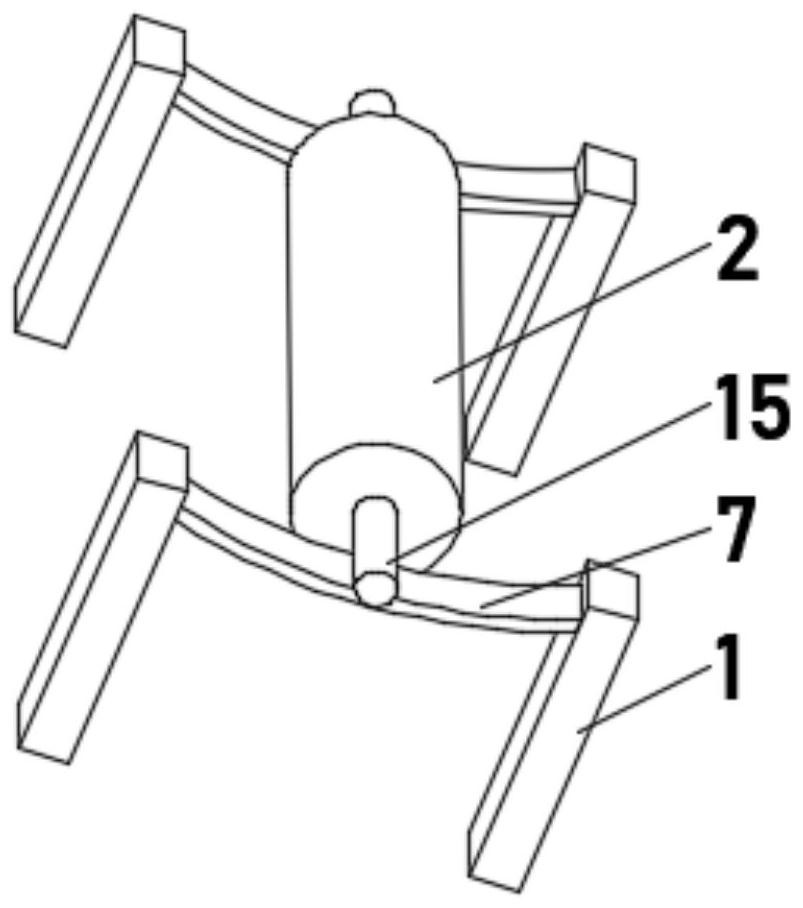

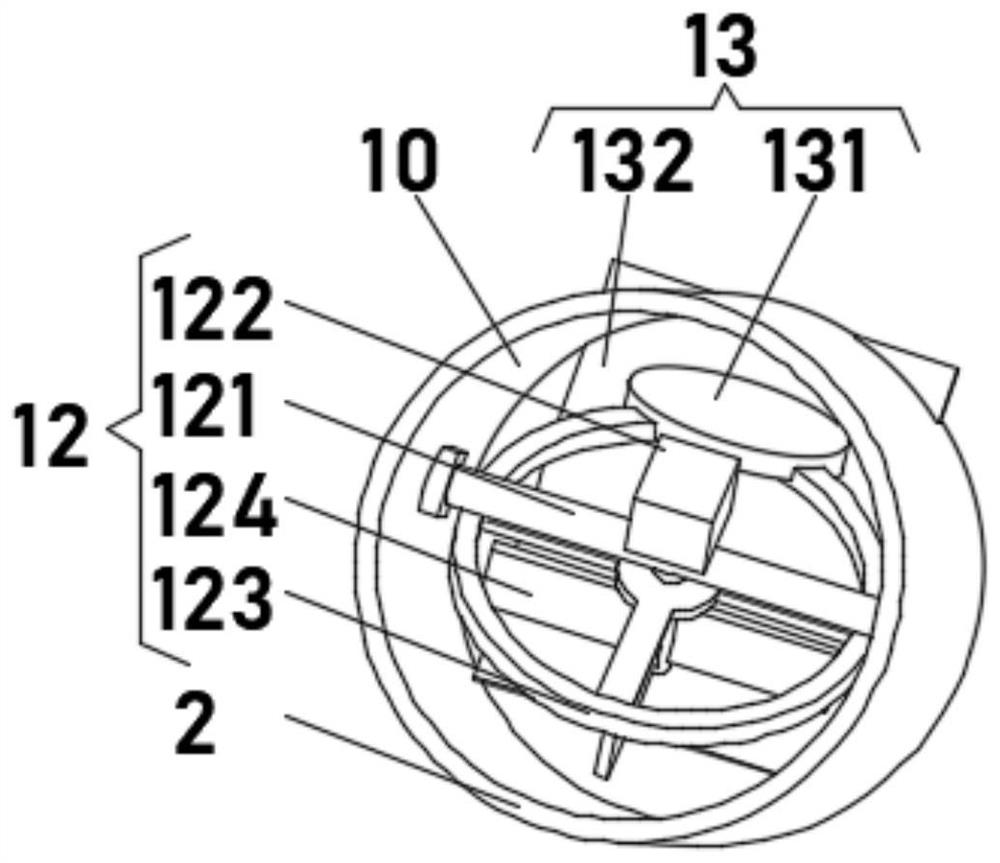

[0033] see Figure 1-3, the present invention provides a technical solution: a printing and dyeing drying device, including a mounting frame 1, characterized in that: the mounting frame 1 is symmetrically installed, a drying rod 2 is installed between the mounting frames 1, and the mounting frame 1 includes a fixed rod 3 and A The top of the type bar 4 and the A-type bar 4 is provided with a guide groove 5, and a guide roller 6 is rotatably connected between the two sides of the inner wall of the guide groove 5, and the side of the fixed bar 3 close to the A-type bar 4 is fixedly connected with a support bar 7, Support bar 7 is slidingly connected with guide roller 6, and one side of drying rod 2 is provided with drainage groove 10, and drainage groove 10 runs through drying rod 2, and the outer side of drying rod 2 is evenly provided with ventilating hole 11, and both ends of drainage groove 10 are installed Drainage device 12 is arranged.

[0034] The drainage device 12 inc...

Embodiment 2

[0039] see Figure 1-3 , the present invention provides a technical solution: on the basis of Embodiment 1, a thrust reverser 13 is installed inside the drainage tank 10 close to the drainage device 12, and the thrust reverser 13 includes a counterweight 131, and the counterweight 131 is installed On the top of the drainage frame 123 , the installation frame 121 is rotatably connected with the inner wall of the drainage groove 10 , and the tops of both ends of the drainage groove 10 are fixedly connected with inclined screen plates 132 .

[0040] During use, due to the gravitational effect of the counterweight 131, the drainage frame 123 and the drainage fan blade 124 are driven to rotate until the counterweight 131 and the drainage motor 122 are respectively located on both sides of the mounting frame 121, so that the drainage frame 123 and the drainage fan blade 124 are rotated again. Stable, the air moves upward to the mobile phase drainage fan blade 124, the flocs in the a...

Embodiment 3

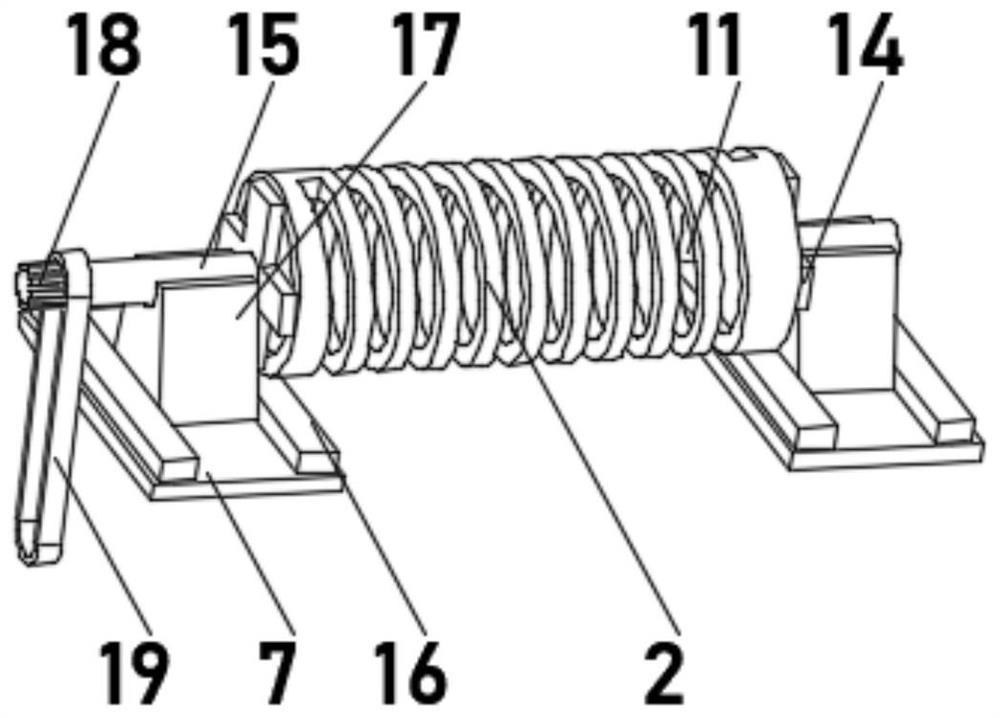

[0042] see Figure 1-5 , the present invention provides a technical solution: on the basis of Embodiment 1, a lifting motor 8 is installed on one side of the A-shaped bar 4, and the output end of the lifting motor 8 is connected to the support bar 7 through a connecting rope 9, and the support bar 7 The limit bar 16 is installed symmetrically on the top, the top of the support bar 7 is slidably connected with the guide frame 17 between the two sides of the limit bar 16, and the top of the rotating rod 15 is rotatably connected with the guide frame 17.

[0043] One end of the rotating rod 15 is fixedly connected with a gear rod 18 , and the outer side of the gear rod 18 is sheathed with a gear chain 19 , and the gear chain 19 meshes with the gear rod 18 .

[0044] During use, put the rotating rod 15 at both ends of the drying rod 2 on the support bar 7, start the lifting motor 8, and the lifting motor 8 pulls the support bar 7 through the connecting rope 9 to move in the direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com