Scrap copper refining process

A waste miscellaneous copper and process technology, which is applied in the direction of photographic process, photographic auxiliary process, process efficiency improvement, etc., can solve the problems of polluted air, recycled copper with low purity waste gas, etc., to reduce pollution, improve purity, and increase reuse rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

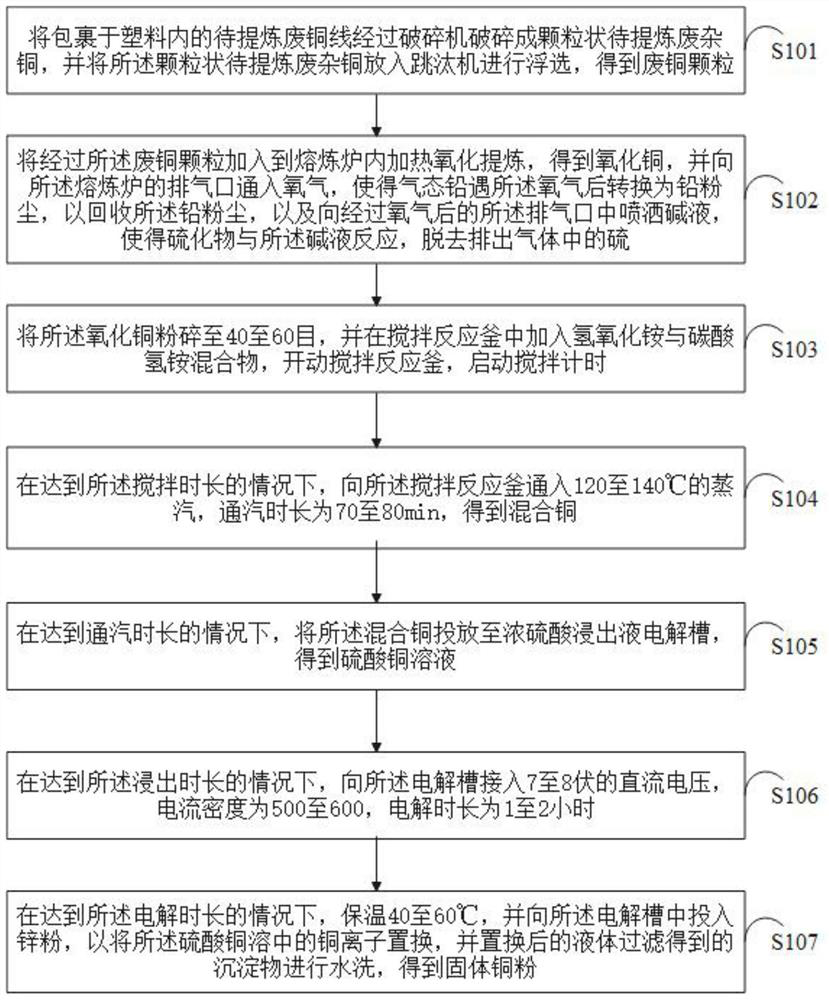

[0046] The scrap copper wire wrapped in plastic is crushed into granular scrap copper to be refined through a crusher.

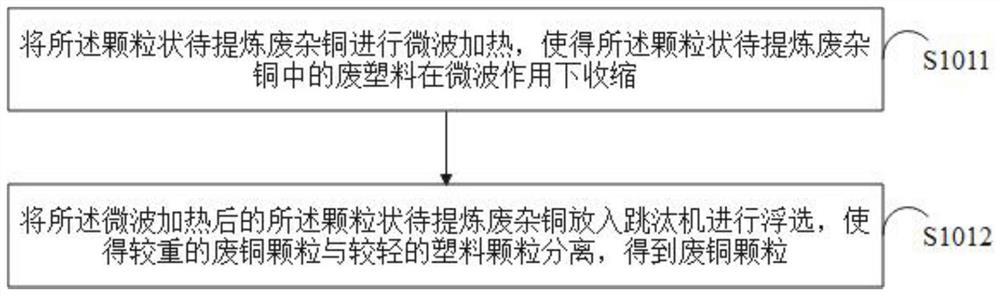

[0047] Microwave heating is performed on the granular waste copper to be refined, so that the waste plastic in the granular waste copper to be refined shrinks under the action of microwaves, wherein the heating time of the microwave heating is 50 minutes, and the microwave heating The heating temperature is 450 degrees Celsius;

[0048] Put the granular scrap copper to be refined after the microwave heating into a jig for flotation, so that the heavier scrap copper particles are separated from the lighter plastic particles to obtain scrap copper particles. The jig Install a filter screen with a filter hole diameter less than or equal to 30mm in order to obtain granular copper with a particle diameter less than or equal to 30mm;

[0049] Put the scrap copper particles into the smelting furnace to heat and oxidize and refine to obtain copper oxide, and introd...

Embodiment 2

[0056] The scrap copper wire wrapped in plastic is crushed into granular scrap copper to be refined through a crusher.

[0057] Microwave heating is performed on the granular waste copper to be refined, so that the waste plastic in the granular waste copper to be refined shrinks under the action of microwaves, wherein the heating time of the microwave heating is 60 minutes, and the microwave heating The heating temperature is 600 degrees Celsius;

[0058] Put the granular scrap copper to be refined after the microwave heating into a jig for flotation, so that the heavier scrap copper particles are separated from the lighter plastic particles to obtain scrap copper particles. The jig Install a filter screen with a filter hole diameter less than or equal to 30mm in order to obtain granular copper with a particle diameter less than or equal to 30mm;

[0059] Put the scrap copper particles into the smelting furnace to heat and oxidize and refine to obtain copper oxide, and introd...

Embodiment 3

[0066] The scrap copper wire wrapped in plastic is crushed into granular scrap copper to be refined through a crusher.

[0067] Microwave heating is carried out on the granular waste miscellaneous copper to be refined, so that the waste plastic in the granular waste miscellaneous copper to be refined shrinks under the action of microwaves, wherein, the heating time of the microwave heating is 50 minutes, and the microwave heating The heating temperature is 500 degrees Celsius;

[0068] Put the granular scrap copper to be refined after the microwave heating into a jig for flotation, so that the heavier scrap copper particles are separated from the lighter plastic particles to obtain scrap copper particles. The jig Install a filter screen with a filter hole diameter less than or equal to 30mm in order to obtain granular copper with a particle diameter less than or equal to 30mm;

[0069] Put the scrap copper particles into the smelting furnace to heat and oxidize and refine to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com