Micron-scale zirconium hydroxide, preparation method and applications thereof

A micron-sized, zirconium hydroxide technology, applied in the chemical field, can solve the problems of uneven distribution of adsorption particles, less particle hole formation, and low adsorption capacity, and achieve simple preparation process, lower dialysis pressure, and good adsorption effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

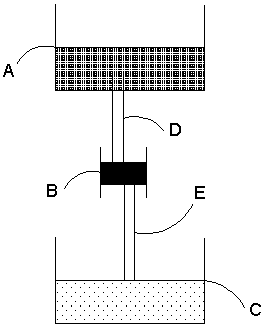

Method used

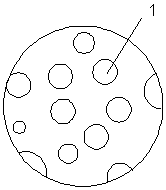

Image

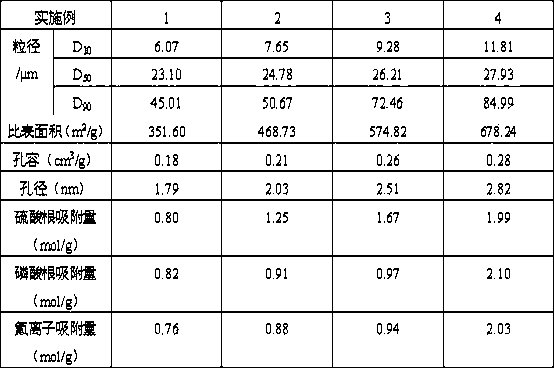

Examples

Embodiment 1

[0029] Preparation concentration is the alkali solution of the sodium hydroxide of 0.6mol / L; o Add 5g zirconium chloride under heating condition, stir for 0.5 hour, control pH value to be 8, then in 80 o C for 18 hours, then at 80 o Suction filtration under C obtains filter residue, and filter residue uses 80 o The water of C is washed 2 times; Add water and stir in the obtained filter residue, the weight ratio of filter residue and water is 1:3, then drip the acetic acid that concentration is 0.8mol / L, control pH value to be 4, leave standstill for 3 hours, then Suction filtration obtains solid, uses 50 o Wash the solid twice with water of C; at 100 o C, heat preservation for 30 minutes under vacuum degree of 0.6atm to obtain micron-sized zirconium hydroxide.

Embodiment 2

[0031] Preparation concentration is the alkali solution of the sodium hydroxide of 0.7mol / L; o Add 6g zirconium chloride under heating condition, stir for 0.5 hour, control pH value to be 9, then in 90 o C for 18 hours, then at 90 o Suction filtration under C obtains filter residue, and filter residue uses 90 o The water of C is washed 1 time; Add water and stir in the obtained filter residue, the weight ratio of filter residue and water is 1:3, then drip the acetic acid that concentration is 2.5mol / L, control pH value to be 5, stand for 3 hours, then Suction filtration obtains solid, uses 60 o The solid was washed twice with water of C; at 120 o C, heat preservation for 35 minutes under vacuum degree of 0.6atm to obtain micron-sized zirconium hydroxide.

Embodiment 3

[0033] Preparation concentration is the alkali solution of the sodium hydroxide of 0.8mol / L; o Add 7g zirconium chloride under heating condition, stir for 0.5 hour, control pH value to be 11, then in 100 o C for 18 hours, then at 100 o Suction filtration under C obtains filter residue, and filter residue uses 90 o The water of C is washed 2 times; Add water and stir in the obtained filter residue, the weight ratio of filter residue and water is 1:3, then drip the acetic acid that concentration is 4.2mol / L, control pH value to be 4, stand for 3 hours, then Suction filtration obtains solid, uses 60 o Wash the solid once with water of C; at 135 o C, heat preservation for 40 minutes under vacuum degree of 0.65 atm to obtain micron-sized zirconium hydroxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com