Acidic Mesoporous Zirconium Phosphate Pillared Activated Clay Deolefination Catalyst

A technology of mesoporous zirconium phosphate and mesoporous phosphoric acid, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as short production cycle, loss of aromatic and other oil bodies, and many operations. To achieve the effect of dense structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

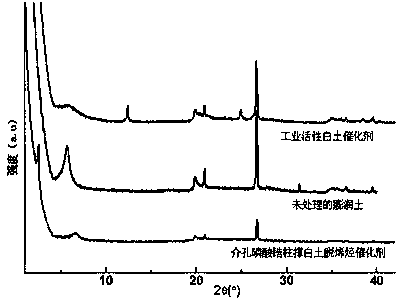

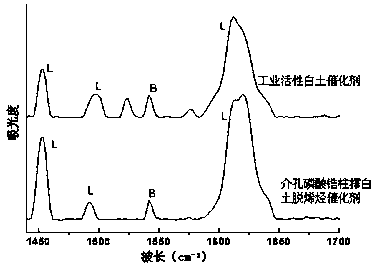

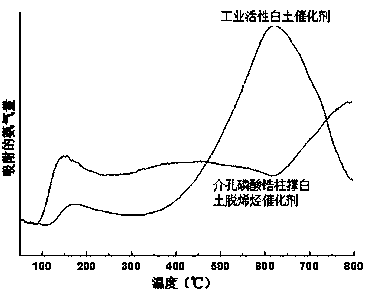

[0025] This embodiment provides an acidic mesoporous zirconium phosphate pillared activated clay deolefination catalyst, which is composed of mesoporous zirconium phosphate and activated bentonite. 12.5%wt, its preparation method is as follows:

[0026] Bentonite pre-treatment:

[0027] Grind and sieve bentonite (Bentonite) raw soil to obtain bentonite powder of about 200 mesh, add deionized water according to the ratio of bentonite powder to deionized water (1:50), fully swell for 7 days, and centrifuge at low speed to remove impurities such as large particles of quartz Then dry to obtain activated bentonite for future use.

[0028] Preparation of mesoporous zirconium phosphate pillared active clay deolefin catalyst:

[0029] Add 15ml of sulfuric acid solution (molar concentration: 0.87mol / L) to 3.2g of zirconium hydroxide, then add 2.5g of CTAB aqueous solution and 2.5g of activated bentonite, stir for 2 hours and then transfer to a stainless steel with Teflon lining for r...

Embodiment approach 2

[0042] This embodiment provides an acidic mesoporous zirconium phosphate pillared activated clay deolefination catalyst, which is composed of mesoporous zirconium phosphate and activated bentonite. 19%wt, its preparation method is as follows:

[0043] Bentonite pre-treatment:

[0044] Grind and sieve bentonite (Bentonite) raw soil to obtain bentonite powder of about 250 mesh, add deionized water according to the ratio of bentonite powder to deionized water (1:75), fully swell for 7 days, and centrifuge at low speed to remove impurities such as large particles of quartz Then dry to obtain activated bentonite for future use.

[0045] Preparation of mesoporous zirconium phosphate pillared active clay deolefin catalyst:

[0046] Add 15ml of sulfuric acid solution (molar concentration: 0.87mol / L) to 3.2g of zirconium hydroxide, then add 3.75g of CTAB aqueous solution and 3.75g of activated bentonite, stir for 2.5h and then transfer to a stainless steel with polytetrafluoroethylen...

Embodiment approach 3

[0048] This embodiment provides an acidic mesoporous zirconium phosphate pillared activated clay deolefination catalyst, which is composed of mesoporous zirconium phosphate and activated bentonite. 25%wt, its preparation method is as follows:

[0049] Bentonite pre-treatment:

[0050] Grind and sieve bentonite raw soil to obtain bentonite powder of about 150 mesh, add deionized water according to the ratio of bentonite powder to deionized water at 1:100, fully swell for 7 days, and centrifuge at low speed to remove impurities such as large particles of quartz Then dry to obtain activated bentonite for future use.

[0051] Preparation of mesoporous zirconium phosphate pillared active clay deolefin catalyst:

[0052] Add 11.5ml of sulfuric acid solution (molar concentration: 0.87mol / L) to 2.4g of zirconium hydroxide, then add 3.75g of CTAB aqueous solution and 3.75g of activated bentonite, stir and react for 1.5h, then transfer to stainless steel with polytetrafluoroethylene l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com