Nanogold-loaded meso-porous silicon material catalyst for formaldehyde room temperature oxidation, preparation and activation method and application

An activation method and mesoporous silicon technology, applied in chemical instruments and methods, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problems of poor activity and stability at room temperature, and achieve the reduction of precious metal consumption, good repeatability, process and The effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Disperse 2.0g of MCM-41 carrier material into 200mL of ethanol, then add 10.0g of APTES to the solution, and stir and reflux at 80°C for 24h to obtain a white emulsion, which is filtered by ethanol, washed twice, and dried in an oven at 80°C for 6h , to obtain APTES-modified MCM-41 material, denoted as APTES@MCM-41.

Embodiment 2

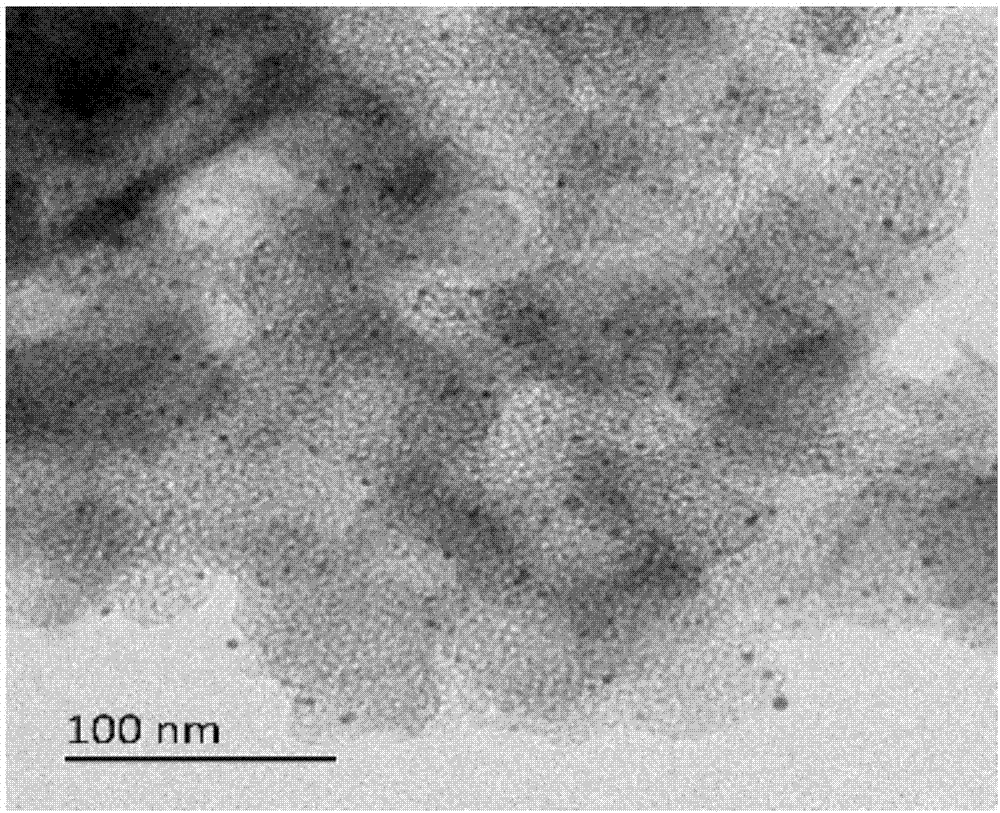

[0027] Weigh 1.0g of APTES@MCM-41 obtained in Example 1 and disperse it into 40mL of deionized water in turn, add 2.1mL of prepared HAuCl 4 solution, after stirring at room temperature for 30min, add 10mL of 0.2M NaBH 4 solution, the color of the solution quickly changed to reddish brown, and continued to stir at room temperature for 30 minutes, filtered and washed with water three times to obtain Au / APTES@MCM-41 with a mass fraction of 1%. The catalyst samples were dried in an oven at 80 °C. The obtained Au / APTES@MCM-41 catalyst was pressed into tablets and passed through a 20-40 mesh sieve to obtain a mesoporous silicon-supported nano-gold catalyst.

Embodiment 3

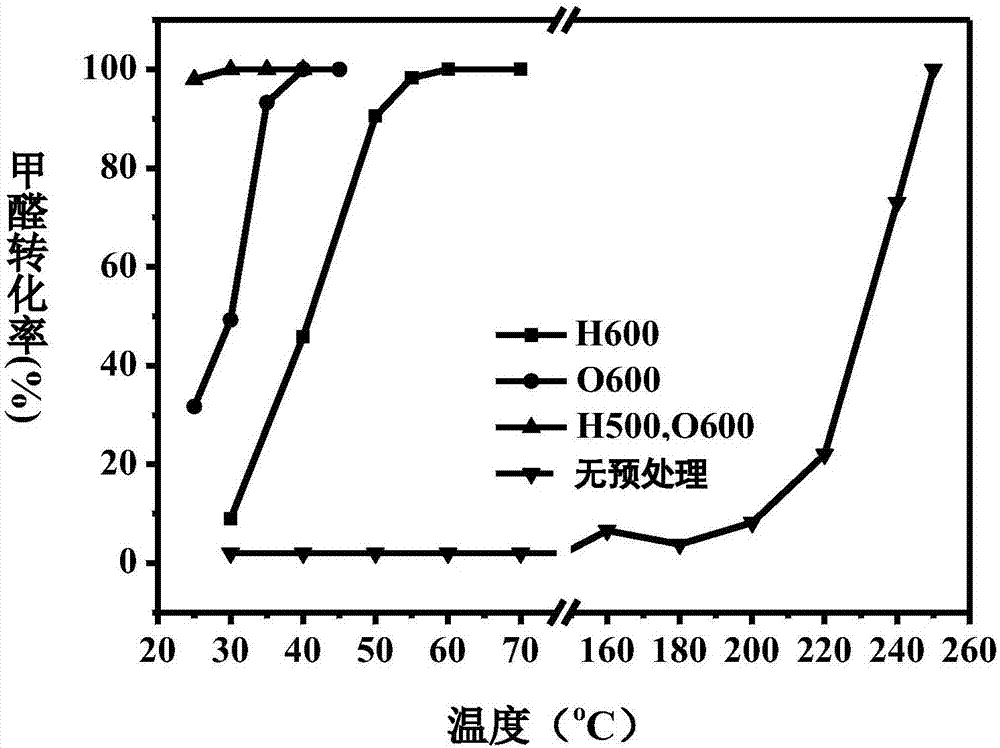

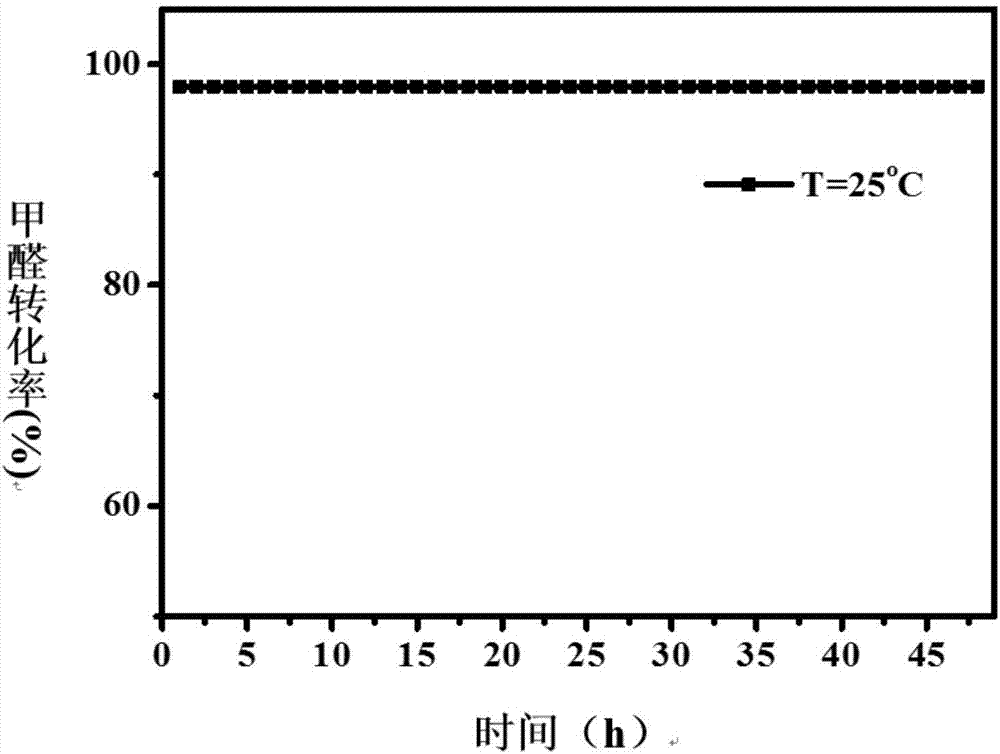

[0029] Weigh 0.2g of the catalyst and put it into a quartz reaction tube, inject Ar gas for 15 minutes to remove the air in the pipeline, and then inject H 2 (30ml / min), treated at 600°C for 1h, the heating rate was 10°C / min; Ar purged to cool down to room temperature. The initial concentration of formaldehyde is 120ppm, and the reaction temperature is 25°C, and the conversion rate of formaldehyde is 9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com