Mesoporous iron-based compound oxide catalyst, preparation method and use thereof to ammonia selective catalytic reduction of nitric oxide

A composite oxide and catalyst technology, which is applied in the field of environmental catalytic purification, can solve problems such as narrow temperature window, poor stability, and insufficient low-temperature activity, and achieve low cost, good thermal stability and sulfur resistance, and excellent medium and low temperature activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Preparation of the mixed template: Add 0.18g of PVP to 200ml of deionized water, stir in a water bath at 30°C, wait until the PVP is completely dissolved and form a transparent solution, add 0.12g of CTAB to the solution, and continue stirring for 3 hours to form a uniform template solution.

Embodiment 2

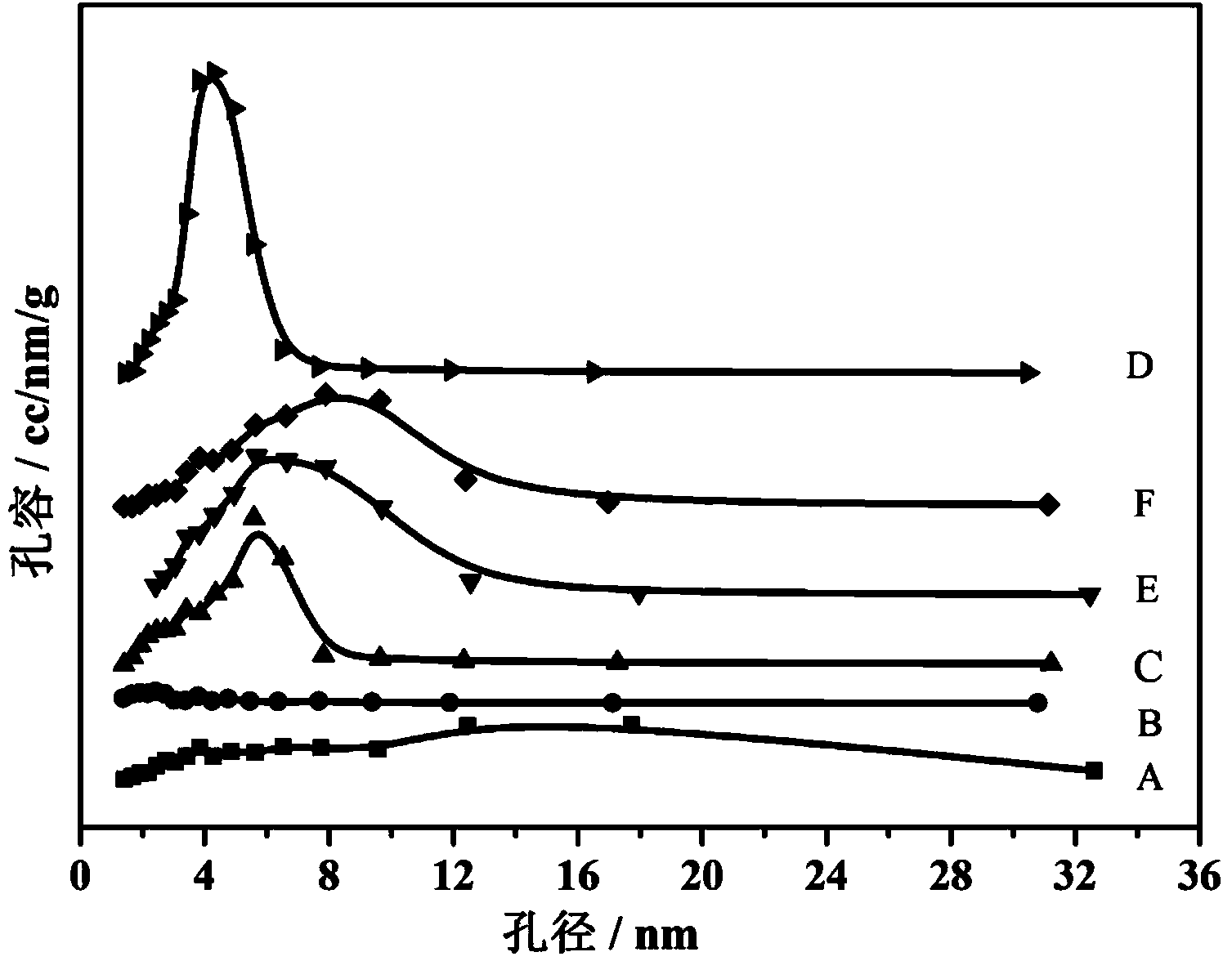

[0021] Preparation of pure oxide catalyst: Weigh 4.04g of ferric nitrate, add it to the template solution prepared above, stir for 3 hours, after the solution is mixed evenly, adjust pH=10 with 0.5mol / L NaOH solution, and keep stirring at 90°C 24h; the obtained precipitate was washed and centrifuged with water and alcohol, dried in an oven at 100°C for 12h, and finally the dried sample precursor was roasted in a muffle furnace at 500°C for 4h to obtain powder catalyst A. Other conditions remained unchanged, and 1.87g of copper nitrate was used instead of ferric nitrate to prepare catalyst B. Other conditions remained unchanged, and 4.34 g of cerium nitrate was used instead of ferric nitrate to prepare catalyst C.

Embodiment 3

[0023] According to the mixed template preparation method of the present invention in Example 1, prepare a composite oxide catalyst: weigh 4.04g of ferric nitrate and 0.73g of copper nitrate, add them to the template solution prepared above, stir for 3h, and wait until the solution is evenly mixed, Use 0.5mol / L NaOH solution to adjust pH=10, and keep stirring at 90°C for 24h; wash and centrifuge the obtained precipitate with water and alcohol, dry it in an oven at 100°C for 12h, and finally place the dried sample precursor in a muffle furnace at 500 Calcined at ℃ for 4h to obtain powder catalyst D.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com