A kind of method for recovering scandium from scandium-containing nickel-cobalt hydroxide

A technology of nickel-cobalt hydroxide and zirconium hydroxide, which is applied in the field of scandium recovery, can solve the problems of resin adsorption, desorption, long regeneration cycle, and low processing efficiency, and achieve the effects of short cycle, high economic value, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

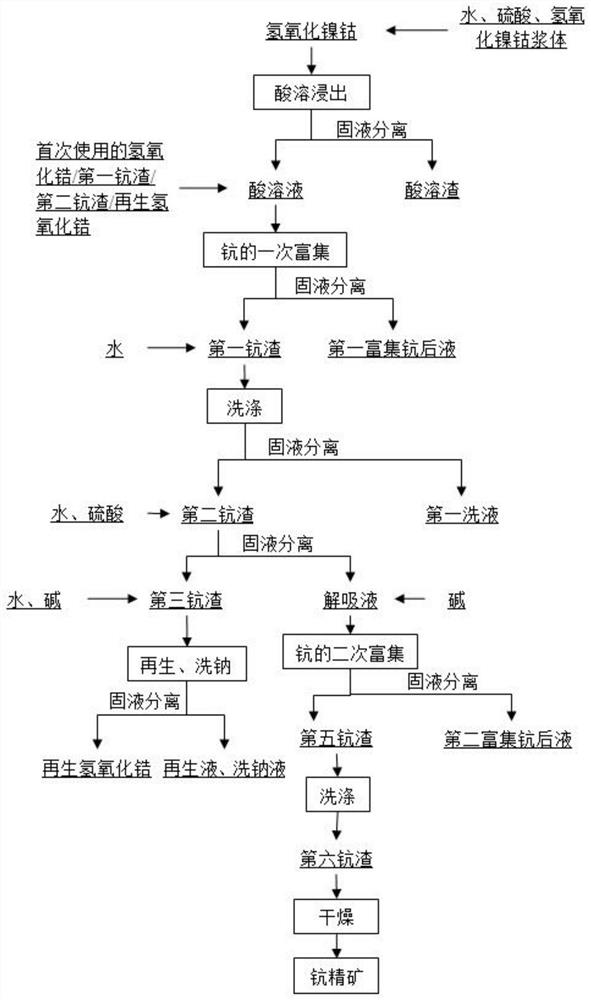

Method used

Image

Examples

Embodiment 1

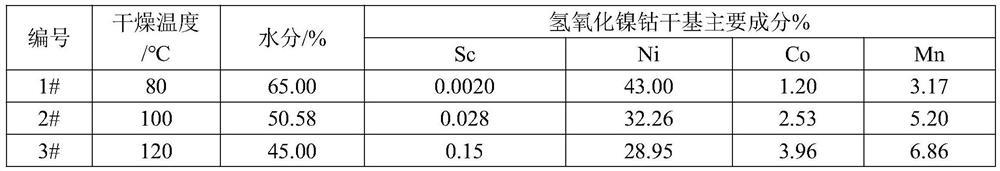

[0033] (1) Acid leaching

[0034] Take 1# nickel cobalt hydroxide (main components shown in Table 1) wet base 10kg, add water to make slurry according to the liquid-solid mass ratio of 0.5:1, heat the slurry in a water bath to 60 ° C, and add a mass fraction of 98% Sulfuric acid was acid-dissolved, and the pH of the acid-dissolving endpoint was controlled to be 1.5. After the constant temperature reaction for 0.5h, the nickel-cobalt hydroxide slurry with a liquid-solid mass ratio of 0.5:1 was added, the pH was adjusted back to 2.5, and the reaction was continued for 0.5h and then filtered to obtain 1 #acid-soluble residue and 1# acid solution, the leaching rate of scandium in liquid meter reaches 93.64%, and the main components of 1# acid solution are shown in Table 2.

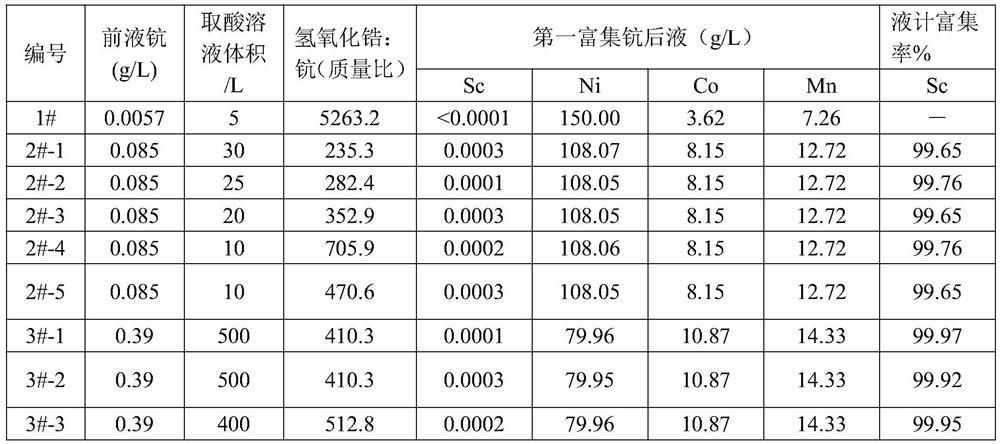

[0035] (2) One enrichment of scandium

[0036] Take 5L of 1# acid solution, slowly add 150g of wet base zirconium hydroxide (water content 40%) used for the first time to it at 20°C, the end point pH is const...

Embodiment 2

[0046] (1) Acid leaching

[0047] Take 2# nickel cobalt hydroxide (the main components are shown in Table 1) wet base 100kg, add water to make slurry according to the liquid-solid mass ratio of 1:1, heat the slurry to 75 ° C, add 98% sulfuric acid for acid dissolution , control the pH of the acid dissolution endpoint to be 1.0, continue to add nickel-cobalt hydroxide slurry with a liquid-solid mass ratio of 1:1 after constant temperature reaction for 0.5h, adjust the pH to 3.0, continue to react for 1.5h and then solid-liquid separation to obtain 2# acid Dissolved slag and 2# acid solution, in which the liquid meter leaching rate of scandium reaches 92.5%, and the main components of 2# acid solution are shown in Table 2.

[0048] (2) One enrichment of scandium

[0049] Take 30L of the 2# acid solution, slowly add 600g of dry base zirconium hydroxide used for the first time to it at 65°C, the end point pH is constant at 5.0 after the reaction for 1h, and the solid-liquid separ...

Embodiment 3

[0060] (1) Acid leaching

[0061] Take 3# nickel cobalt hydroxide (main components are shown in Table 1) wet base 1000kg, add water to make slurry according to the liquid-solid mass ratio of 1.5:1, heat the slurry to 90 ° C, add 98% sulfuric acid for acid dissolution , control the pH of the acid solution endpoint to be 1.3, continue to add nickel-cobalt hydroxide slurry with a liquid-solid ratio of 1.5:1 after the constant temperature reaction for 0.5h, adjust the pH to 3.5, continue to react for 3.5h and then solid-liquid separation to obtain 3# acid solution Slag and 3# acid solution, in which the liquid meter leaching rate of scandium reaches 92.18%, and the main components of 3# acid solution are shown in Table 2.

[0062] (2) One enrichment of scandium

[0063] Take 500L of 3# acid solution, slowly add 80kg of wet-base zirconium hydroxide (moisture 60%) used for the first time to it at 90°C, the end point pH is constant at 4.5 after the reaction for 2h, and the solid-liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com