Solid superacid, preparation method of solid superacid, glycerinum cyclohexanone ketal and preparation method of glycerinum cyclohexanone ketal

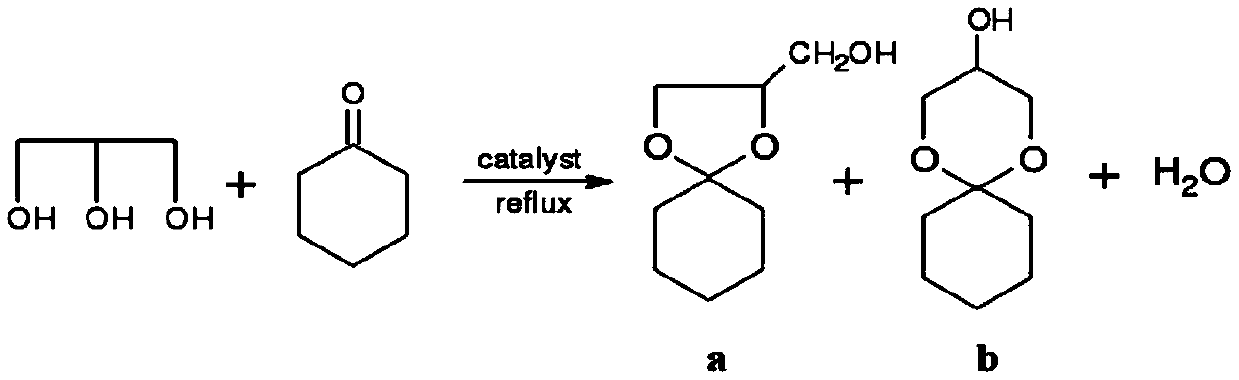

A cyclohexanone ketal, solid super acid technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems such as poor catalytic activity of solid super acid catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

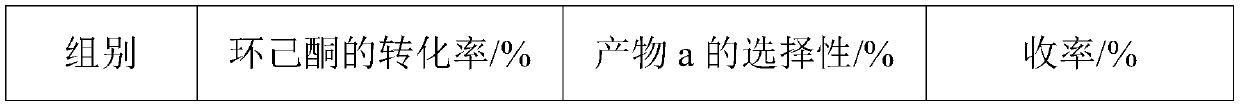

Examples

preparation example Construction

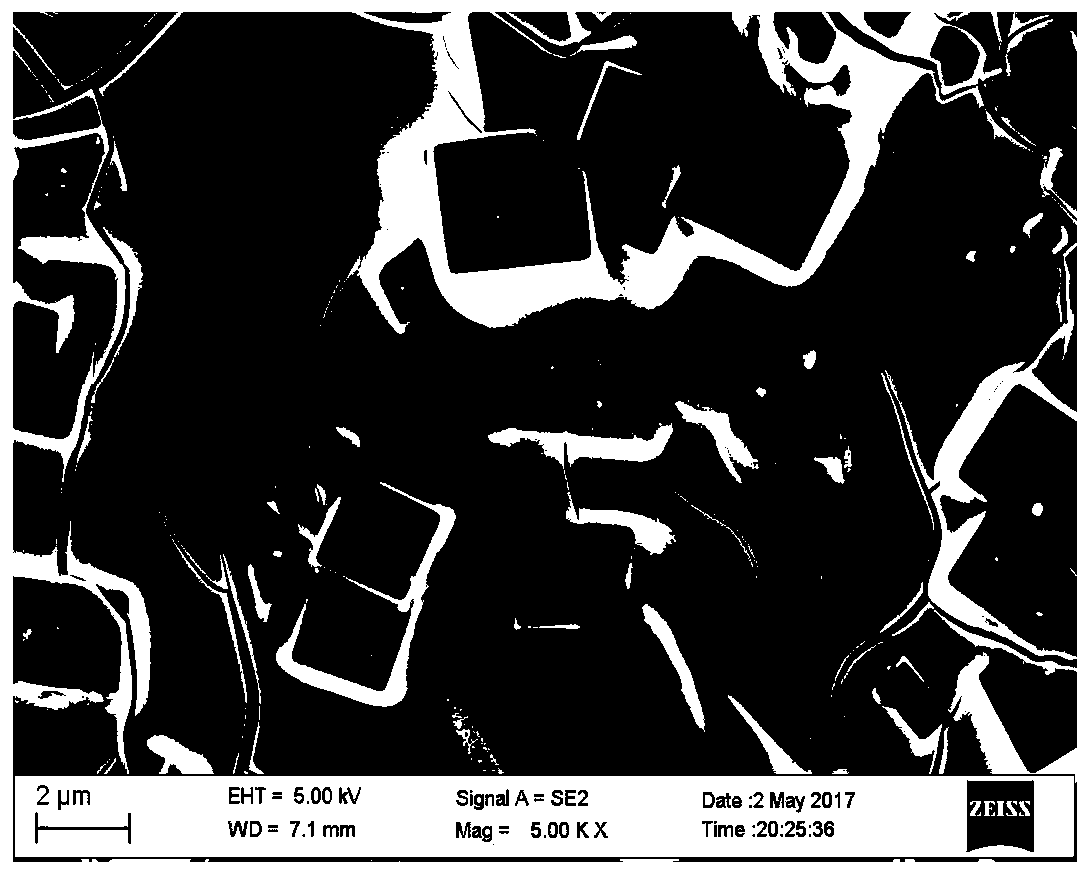

[0022] A kind of preparation method of solid superacid catalyst is provided in one embodiment of the present invention, it comprises the steps:

[0023] Immerse zirconium hydroxide in 0.4mol / L-0.6mol / L ammonium persulfate aqueous solution, filter to obtain a filter cake; dry and roast the filter cake to obtain a solid superacid catalyst, wherein the hydroxide The mass volume ratio of zirconium to the ammonium persulfate aqueous solution is (0.114-16.6): 1g / mL.

[0024] Specifically, in the step of impregnating zirconium hydroxide in 0.4mol / L-0.6mol / L ammonium persulfate aqueous solution and filtering to obtain the filter cake, impregnating zirconium hydroxide in 0.4mol / L-0.6mol / L ammonium persulfate aqueous solution for 12-36h, and suction filtered to obtain a filter cake. The advantage of suction filtration is to remove free water, so as to avoid the formation of water vapor pressure during drying and roasting, which is unfavorable for the preparation of catalysts. Addition...

Embodiment 1

[0046] A preparation method for a solid superacid catalyst, comprising the steps of:

[0047] Weigh 24g of ZrOCl 2 ·8H 2 O is dissolved in the distilled water of 240mL and is configured into the ZrOCl that mass fraction is 10% 2 Solution, in the state of stirring at a constant speed, slowly add ammonia water dropwise, adjust the pH to 10, stop adding ammonia water, and obtain a white precipitate, leave the above precipitate at room temperature for 24h, carry out suction filtration, and wash with deionized water until Until there is no chloride ion (no white precipitate is detected by 0.1mol / L silver nitrate), it is dried in a blast drying oven at 120°C, taken out and ground to obtain zirconium hydroxide.

[0048] Immerse 6g of zirconium hydroxide in 100mL of 0.5mol / L (NH4) 2 S 2 o 8 solution for 24 hours, then suction-filtered to obtain a filter cake, which was then dried at 100°C for 12 hours, placed in a muffle furnace and roasted at a temperature of 600°C for 4 hours t...

Embodiment 2

[0052] A kind of preparation method of solid superacid catalyst, its preparation method is substantially identical with embodiment 1, and difference is that 16g zirconium hydroxide is impregnated in 0.5mol / L (NH ) 2 S 2 o 8 24h in 50mL solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com