Method for high resource treatment of cyclohexanone waste saponification lye

A waste lye and recycling technology, which is applied in chemical instruments and methods, natural water treatment, water/sewage multi-stage treatment, etc., can solve the problem of insufficient added value of chemical resources, achieve significant economic benefits, low energy consumption, The effect of significant social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

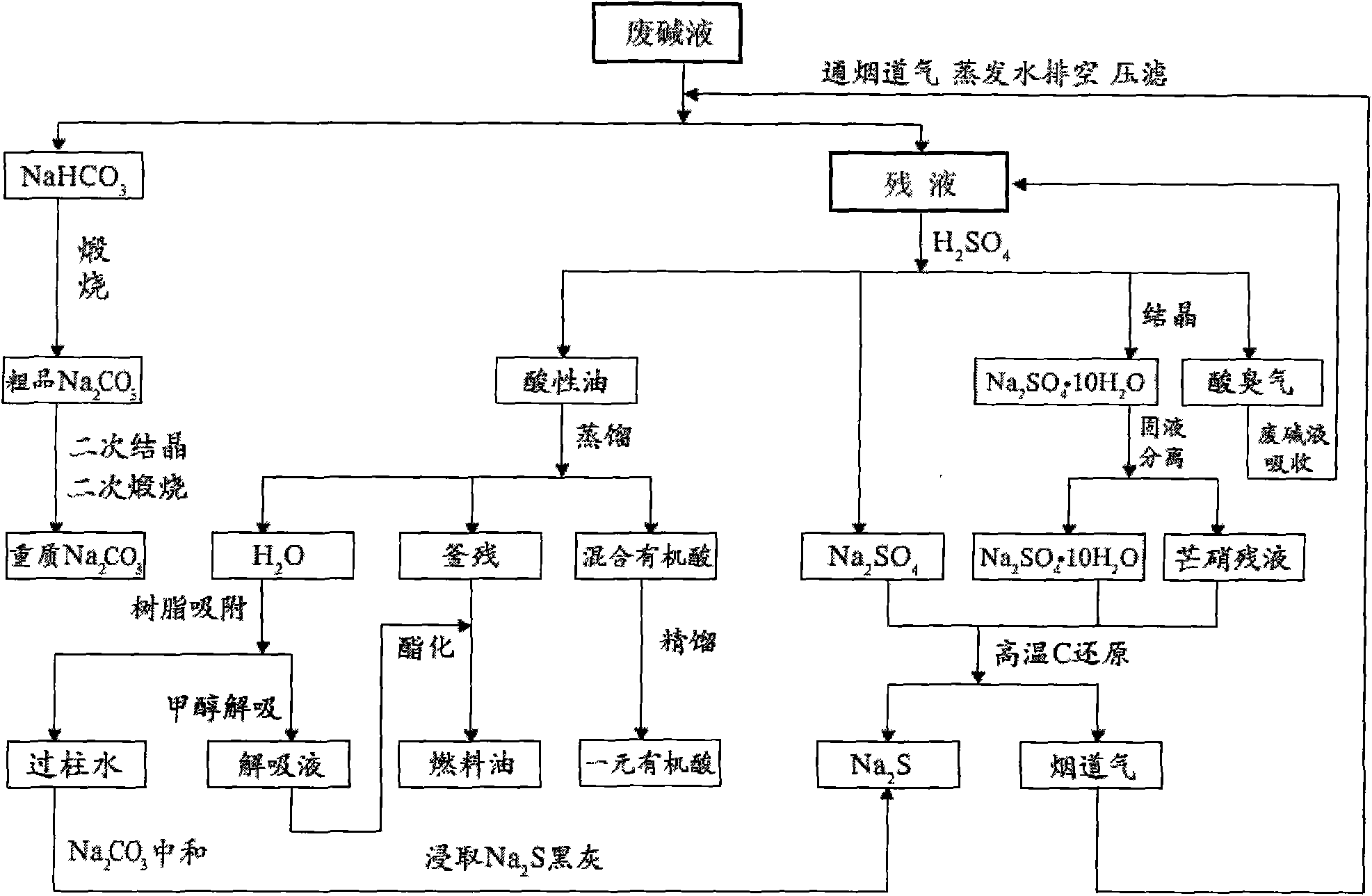

Image

Examples

Embodiment Construction

[0022] The waste caustic lye basic substance component and weight percentage that the inventive method radically cures are:

[0023] Inorganic matter: sodium carbonate (Na 2 CO 3 ) about 7%

[0024] Sodium hydroxide (NaOH) about 8%

[0025] Organic matter: about 35% of organic acids, alcohols, ketones, and esters

[0026] Water about 50%

[0027] Below in conjunction with technological process block diagram, briefly describe the implementation process of the inventive method:

[0028] (1) Reaction of spent lye with flue gas

[0029] When the sodium sulfide is co-produced later, the high-temperature flue gas generated by the rotary furnace is passed into the atomization tower, and the high-efficiency atomizer in the atomization tower fully atomizes the waste lye and fully reacts with the carbon dioxide in the flue gas. reaction, and the dust in the flue gas is adsorbed by the way of water film dedusting, absorbing carbon dioxide, sulfur dioxide, nitrogen oxides, etc. in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com