Hydrogenation catalyst and preparation method and application thereof

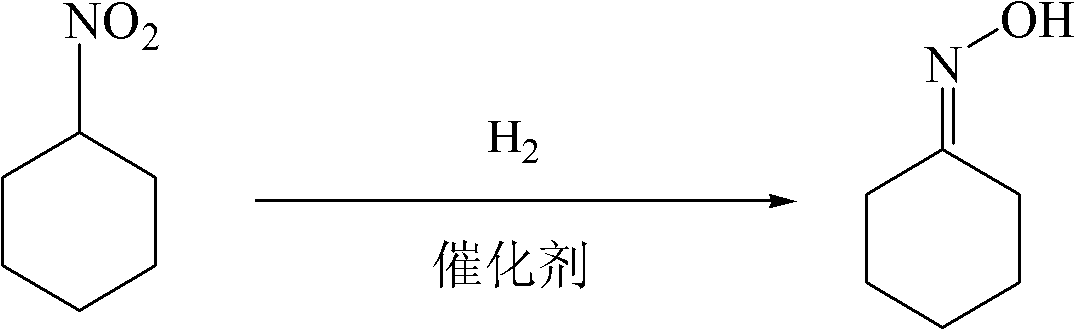

A technology for the preparation of catalysts and hydrogen, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problems of low yield of cyclohexanone oxime and achieve improved Yield, the effect of excellent hydrogenation catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Put 10 grams of carbon nanotubes into 100 milliliters of 20% hydrochloric acid for ultrasonic vibration for 1 hour, and let stand overnight. Then put the carbon nanotubes into 100 ml of nitric acid with a mass concentration of 35% to reflux for 12 hours, filter, wash with deionized water, dry in vacuum and set aside. 1 g of PdCl 2 Dissolve in 50 ml of 4% hydrochloric acid, add the above carbon nanotubes, and add 1 ml of 1% NaOH solution. Stir and soak for 8 hours and then filter. Dry under vacuum at 110°C for 12 hours. Calcined at 200° C. for 4 hours under the protection of nitrogen, reduced by flowing hydrogen at 250° C. for 4 hours, and lowered the temperature under the protection of nitrogen to obtain the catalyst.

[0033] 80 grams of ethylenediamine are added to the reactor, then 12 grams of nitrocyclohexane (purity in 95%) and the hydrogenation catalyst of 1.5 grams of carbon nanotube supported palladium-sodium are added in the kettle, the air is replaced and t...

Embodiment 2

[0035] Put 10 grams of carbon nanotubes into 100 milliliters of 30% hydrochloric acid for ultrasonic vibration for 1 hour, and let stand overnight. Then put the carbon nanotubes into 100 ml of nitric acid with a mass concentration of 60% to reflux for 12 hours, filter, wash with deionized water, dry in vacuum and set aside. 1.5 g PdCl 2 Dissolve in 50 ml of 4% hydrochloric acid, add the above carbon nanotubes, and add 1 ml of 2% NaOH solution. Stir and soak for 8 hours and then filter. Dry under vacuum at 110°C for 12 hours. Calcined at 200° C. for 4 hours under the protection of nitrogen, reduced by flowing hydrogen at 250° C. for 4 hours, and lowered the temperature under the protection of nitrogen to obtain the catalyst.

[0036] 65 grams of ethylenediamine are added to the reactor, then 10 grams of nitrocyclohexane (purity in 95%) and 1 gram of carbon nanotube supported palladium-sodium hydrogenation catalyst are added in the still, the air is replaced and the gas is ch...

Embodiment 3

[0038] Put 10 grams of carbon nanotubes into 100 milliliters of 40% hydrochloric acid for ultrasonic vibration for 1 hour, and let stand overnight. Then put the carbon nanotubes into 100 ml of nitric acid with a mass concentration of 65% to reflux for 12 hours, filter, wash with deionized water, dry in vacuum and set aside. 2.5 g PdCl 2 Dissolve in 50 ml of 4% hydrochloric acid, add the above carbon nanotubes, and add 1 ml of 4% NaOH solution. Stir and soak for 8 hours and then filter. Dry under vacuum at 110°C for 12 hours. Calcined at 250° C. for 4 hours under the protection of nitrogen, reduced with hydrogen at 250° C. for 4 hours, and lowered the temperature under the protection of nitrogen to obtain a catalyst.

[0039] 50 grams of ethylenediamine are added to the reactor, and then 8 grams of nitrocyclohexane (purity is in terms of 95%) and 0.6 gram of carbon nanotube supported palladium-sodium hydrogenation catalyst are added in the kettle, the air is replaced and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com