Preparation method of one-dimensional mesoporous Co nanowire array

A nanowire array and mesoporous technology, applied in the field of inorganic nanomaterial synthesis, can solve the problems of inability to prepare one-dimensionally oriented mesoporous nanostructures, inability to obtain one-dimensional magnetic Co nanostructures, and inability to obtain SBA structures, etc. The preparation process is easy to operate, small mesopore size, and the effect of large specific surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

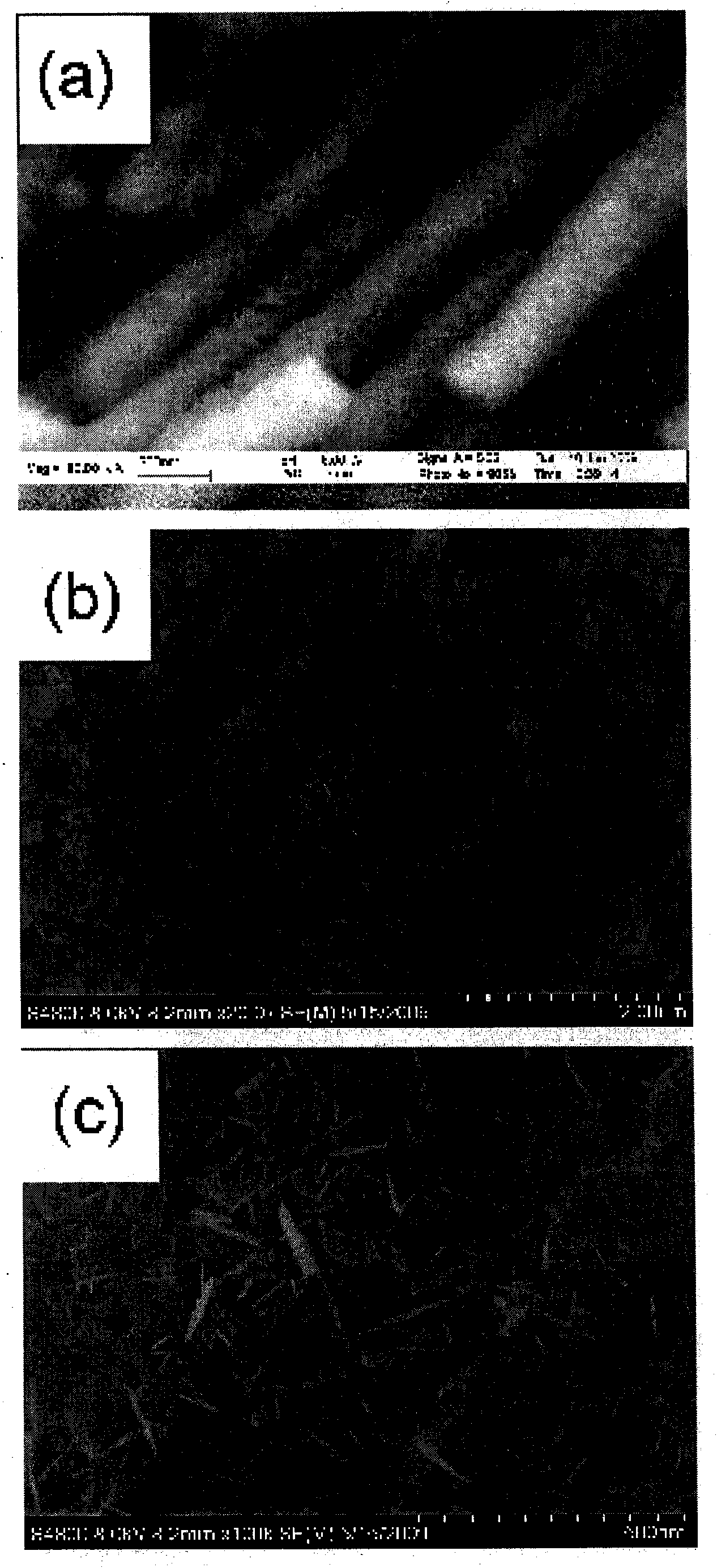

[0022] 1) Preparation of porous alumina template by one-step anodic oxidation method

[0023] The annealed aluminum sheet was put into an electrolytic cell, 0.36 mol / mL phosphoric acid was used as the electrolyte, and an oxidation voltage of 120V was applied at 0-5°C for oxidation, and the oxidation time was 60 hours. Then the prepared alumina template is immersed in 0.36 mol / mL phosphoric acid solution for 2-3 hours. This step is used to expand the pore size of the porous alumina template.

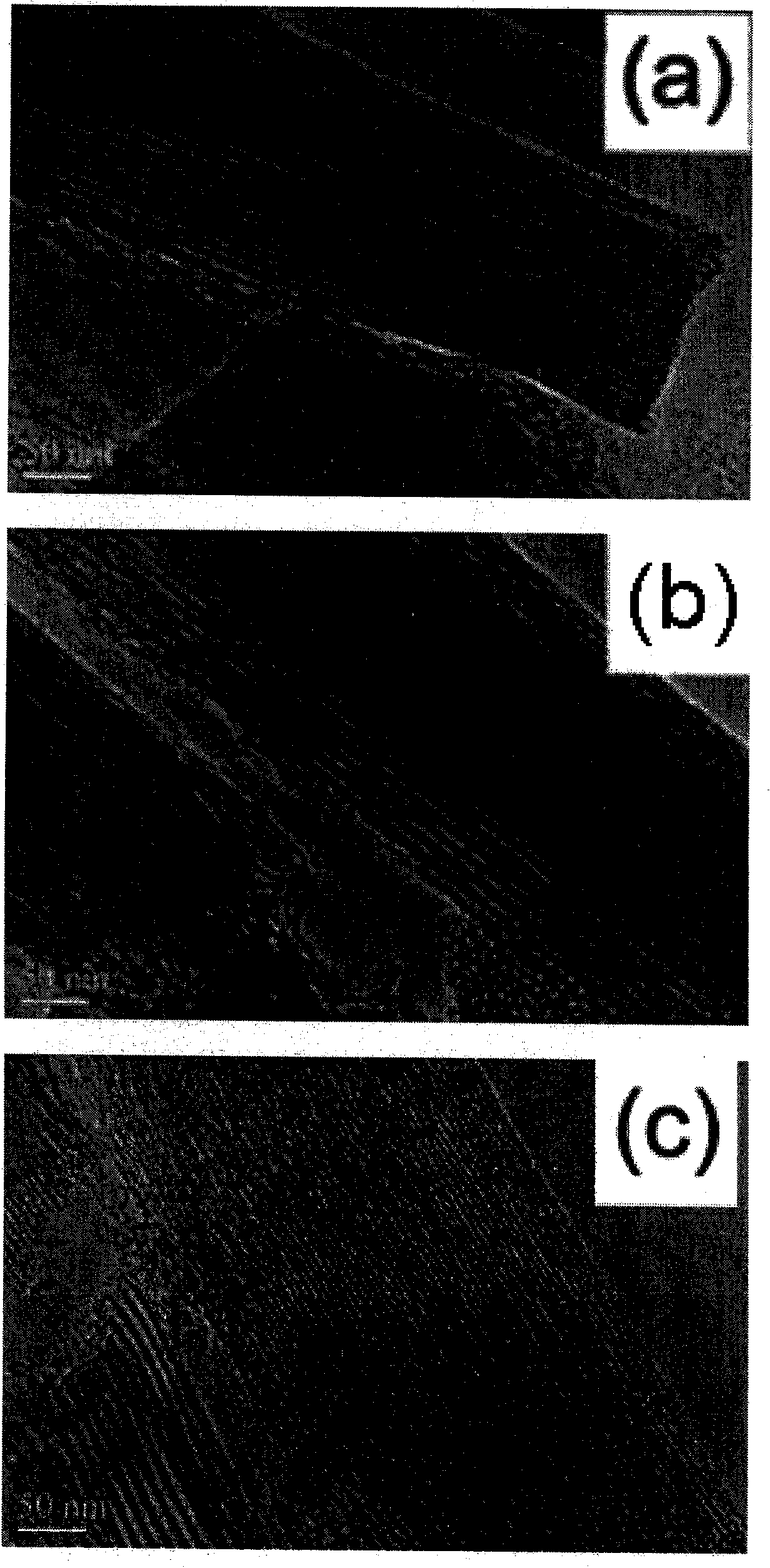

[0024] 2) Preparation of AAO-SBA composite mesoporous template with mesoporous channels parallel to AAO channels

[0025] At room temperature, 0.6 g of P123 and 40 ml of ethanol were mixed uniformly. Then, 0.93 g of tetraethyl orthosilicate and 0.4 g of hydrochloric acid (38 wt%) were added dropwise, and stirring was continued to make the solution uniformly mixed to obtain a precursor solution. At room temperature, the prepared porous alumina template was immersed in the precursor solution for...

Embodiment 2

[0036] 1) Prepare porous alumina template by one-step anodic oxidation method (same as Example 1)

[0037] 2) Preparation of AAO-SBA composite mesoporous template with mesoporous channels parallel to AAO channels

[0038] At room temperature, mix 0.5 g of P123 and 40 ml of ethanol. Then, 0.93g of tetraethylorthosilicate and 0.4g of hydrochloric acid (38wt%) were added dropwise, and stirring was continued to make the solution evenly mixed, and the prepared AAO template was soaked in the precursor solution for 20h. After that, the alumina template was taken out and dried at 50°C for 13 hours, and then kept at 400°C for 5 hours.

[0039] 3) Removal of SiO on the surface of the composite mesoporous template 2 Oxide layer (same as Example 1)

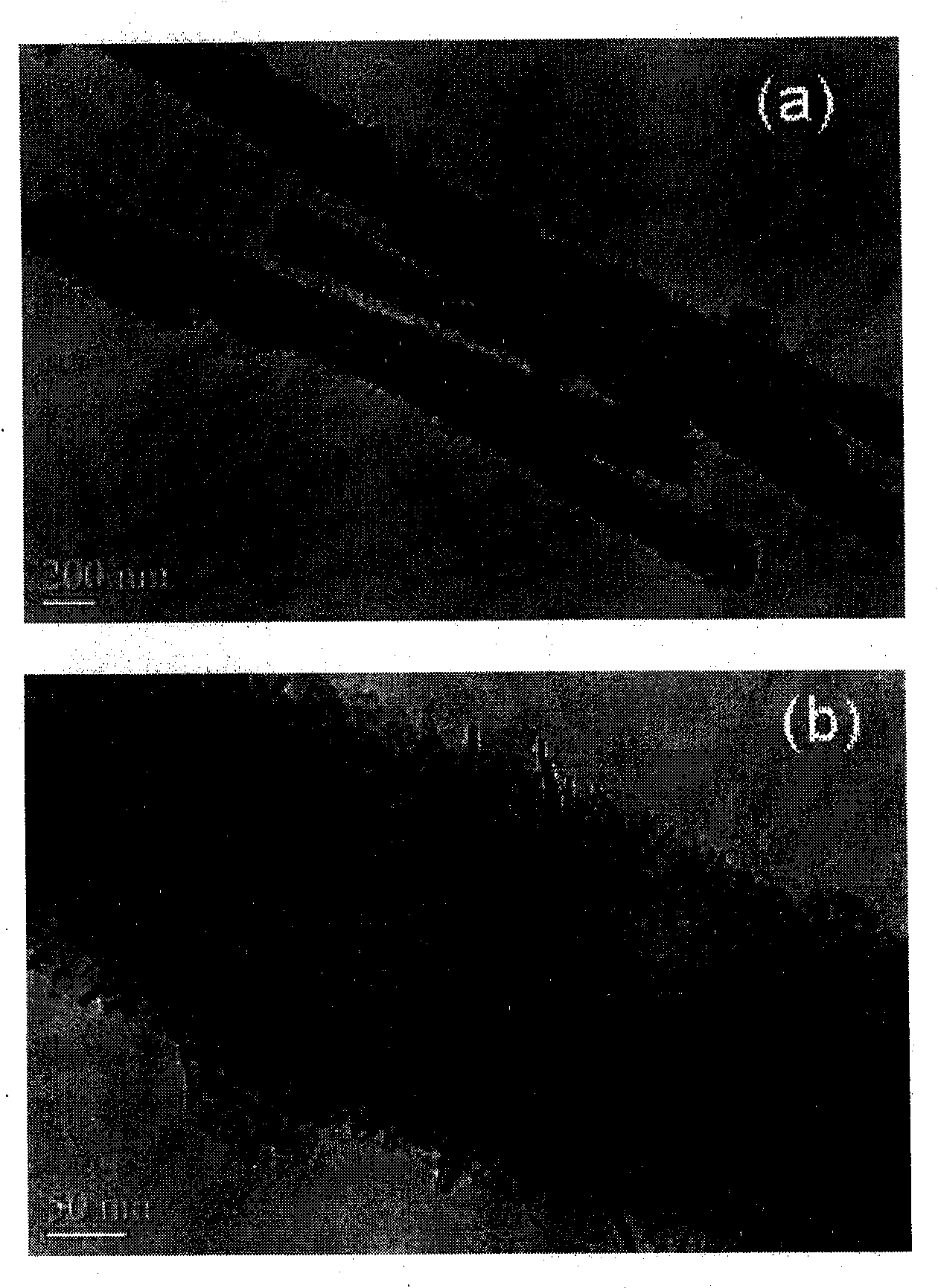

[0040] 4) Preparation of one-dimensional mesoporous Co nanowires

[0041] Weigh 2 g of cobalt acetate and 2 g of boric acid and dissolve in 100 mL of distilled water, and stir until the cobalt acetate and boric acid are all dissolved and mixed unifor...

Embodiment 3

[0043] 1) Prepare porous alumina template by one-step anodic oxidation method (same as Example 1)

[0044] 2) Preparation of AAO-SBA composite mesoporous template with mesoporous channels parallel to AAO channels

[0045] At room temperature, 0.7g of P123 and 40ml of ethanol were mixed uniformly. Then, 0.93g of tetraethylorthosilicate and 0.4g of hydrochloric acid (38wt%) were added dropwise respectively, and stirring was continued to make the solution evenly mixed, and the prepared AAO template was soaked in the precursor solution for 22h. Then it was dried at 70°C for 15 hours, and then kept at 500°C for 6 hours.

[0046] 3) Removal of SiO on the surface of the composite mesoporous template 2 Oxide layer (same as Example 1)

[0047] 4) Preparation of one-dimensional mesoporous Co nanowires

[0048] Weigh 2 g of cobalt acetate and 3 g of boric acid and dissolve in 100 mL of distilled water, and stir until the cobalt acetate and boric acid are all dissolved and mixed uniformly. Contr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com