Method for preparing iron phosphate with micro/nano structure

A micro-nano structure, iron phosphate technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of large particle size, equipment requirements, low reactivity, etc. The effect of control and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

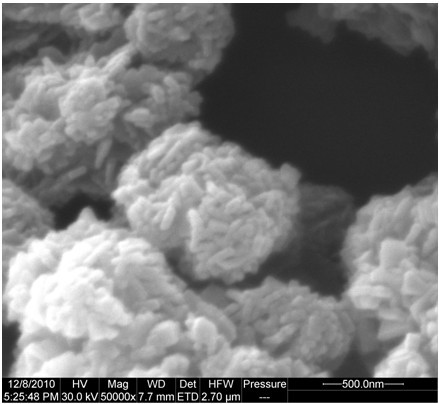

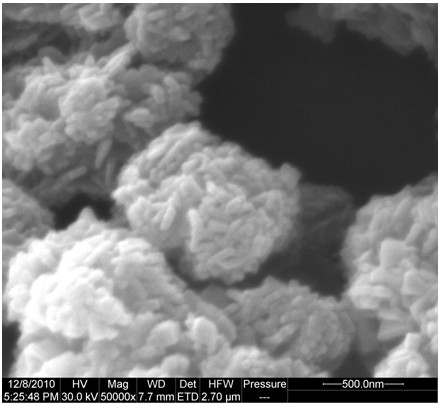

Image

Examples

Embodiment 1

[0017] Measure 1000 grams of 10wt% ferrous sulfate solution and 80 grams of 85wt% phosphoric acid solution respectively, add them to the reactor, add 27wt% hydrogen peroxide, and after 3 hours, add 86 grams of polyvinyl alcohol PVA1788, heat up to 50 ° C, turbulent flow After circulating for 20 minutes, add 5wt% sodium hydroxide solution within 15 minutes and control the pH value to 2.1; after adding alkali, continue to circulate in turbulent flow for 30 minutes, and then stand and age for 120 minutes. Filter, wash with deionized water at 50°C for 3 times, dry at 120°C for 10 hours, and then process at 300°C to obtain 2 micron iron phosphate clusters.

Embodiment 2

[0019] Measure 500 grams of 20wt% ferrous sulfate solution and 80 grams of 85wt% phosphoric acid solution respectively, add them to the reactor, and let air flow in until the solution turns brown. After 5 hours, add 17 grams of polyoxyethylene ether AEO-9 , the temperature was raised to 90°C, after turbulent circulation for 60 minutes, 15wt% sodium hydroxide solution was added within 40 minutes and the pH value was controlled to 3.0; after adding alkali, the turbulent circulation was continued for 60 minutes, and then left to age for 200 minutes. Filter, wash with deionized water at 50°C for three times, dry at 120°C for 10 hours, and then process at 500°C to obtain iron phosphate clusters with a diameter of 500 nm.

Embodiment 3

[0021] Measure 1000 grams of 25wt% ferrous sulfate solution and 190 grams of 85wt% phosphoric acid solution respectively, add them to the reactor, and feed oxygen until the solution turns brown. After 4 hours, add 95 grams of polyoxyethylene ether AEO-9 , heat up to 70°C, after turbulent circulation for 40 minutes, add 20wt% sodium hydroxide solution within 90 minutes and control the pH value to 3.5; Filter, wash with deionized water at 50°C for three times, dry at 120°C for 10 hours, and then process at 600°C to obtain 200nm iron phosphate clusters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com