Preparation method of magnesium hydroxide powder

A technology of magnesium hydroxide and light-burned magnesium oxide, which is applied in the direction of magnesium hydroxide and nanotechnology, can solve the problems that the performance of magnesium hydroxide needs to be improved, and achieve easy control of the microstructure, easy control of the average particle size, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The present embodiment discloses a kind of preparation method of magnesium hydroxide powder. Specific examples are as follows:

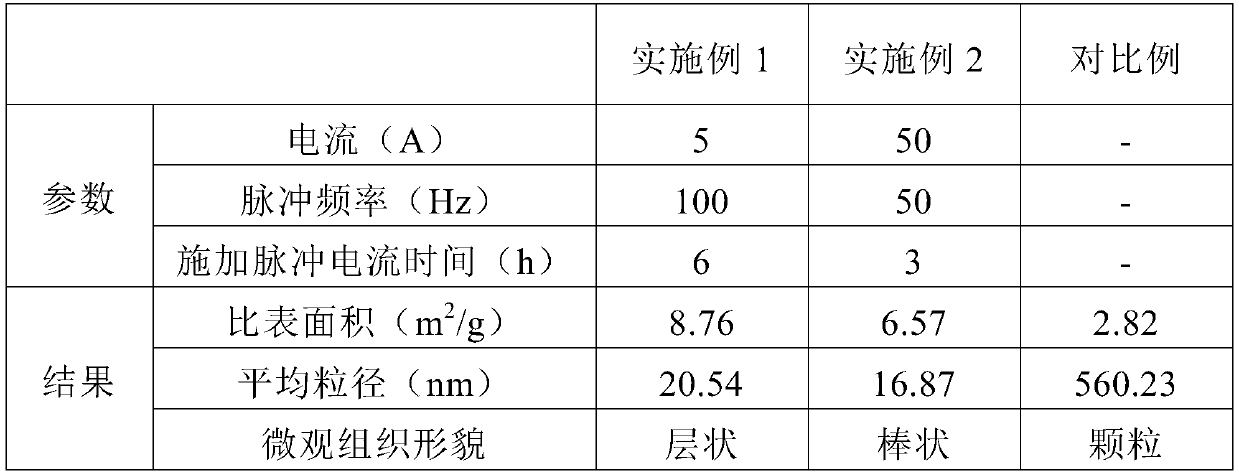

[0015] Example 1: Weigh 1000 g of light-burned magnesium oxide and place it in a reaction tank. The main chemical composition of light-burned magnesia is: MgO 95.26%, SiO 2 0.69%, CaO 1.45%, Al 2 o 3 0.18%, Fe 2 o 3 0.09%. Add 2000L of water into the reaction tank, and fully stir with light-burned magnesia. The reaction tank was heated to a constant temperature of 75° C., and then a pulse current was applied on both sides of the reaction tank. The current magnitude was 5 V, the pulse frequency was 100 Hz, and the pulse current was applied for 6 hours.

[0016] After the reaction, the hydrated magnesium hydroxide was taken out from the reaction tank, and dried at 120° C. for 12 hours. For the dried magnesium hydroxide powder, its specific surface area and average particle size were measured, and its microstructure was observed with an...

Embodiment 2

[0018] Weigh 1000 g of light-burned magnesium oxide and place it in a reaction tank. The main chemical composition of light-burned magnesium oxide is the same as in Example 1. Add 2000L of water into the reaction tank, and fully stir with light-burned magnesia. The reaction tank was heated to a constant temperature of 75° C., and then a pulse current was applied to both sides of the reaction tank. The current was 50 V, the pulse frequency was 50 Hz, and the pulse current was applied for 3 hours.

[0019] After the reaction, the hydrated magnesium hydroxide was taken out from the reaction tank, and dried at 120° C. for 12 hours. For the dried magnesium hydroxide powder, its specific surface area and average particle size were measured, and its microstructure was observed with an electron microscope. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com