Patents

Literature

54results about How to "Control specific surface area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High performance lithium ionic cell cathode material and method for producing the same

InactiveCN101162775AImprove uniformityImprove overall electrical performanceElectrode manufacturing processesSolventLithium electrode

The present invention belongs to a high-performance lithium-ion battery cathode material and a method for preparing the same; solvent, resin and asphalt are added to a container and graphite grains are then added by stirring; the solvent is steamed out through heating up and decompression to form the graphite coated with resin and asphalt which is then put to an inert atmosphere charring furnace for heat treatment; the graphite is cooled to the cycle process less than 100 DEG C after 1 hour to 10 hours; material is taken out, smashed and sieved to grains with grain diameter less than 5 um; after the accumulated volume fraction of grains is less than 10 percent, the high-performance lithium-ion battery cathode material is achieved. As the graphite grains are covered with mixed high molecular polymer made of resin and asphalt, not only the advantages of the resin and asphalt are used, but also the resin has the characteristics of solving asphalt and having condensation polymerization with asphalt, thereby the uniformity, operability and electrical property of covering the graphite grains are improved. By adjusting the proportion of asphalt to resin and controlling the specific surface area of covering graphite grains, the invention has different cycle stability and multiplying power property.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

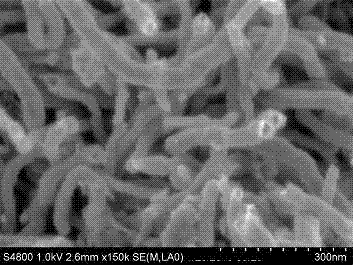

Conductive additive for lithium ion battery and preparation method thereof

ActiveCN102263265AImprove conductivityImprove performanceCell electrodesSodium-ion batteryMagnification

The invention discloses a lithium ion battery conductive additive and a preparation method thereof, and solves the technical problems of improving the conductive performance and cycle life of anode and cathode materials of a lithium ion battery. The lithium ion battery conductive additive is graphene, is black powder with grain size distribution of between 10 nanometers and 100 microns, and is a carbonaceous material consisting of single or 1,000 parallel or approximately parallel graphene lamellae. The preparation method comprises oxidization and stripping reduction. Compared with the prior art, the additive has higher electric conductivity; when the additive is applied to the electrode material, the performance of the conventional battery can be greatly improved only by a little amount; the material serving as the conductive additive has good conductive performance, is easy for dispersion, and can effectively enhance the conductive performance and the magnification charging and discharging performance of the electrode material of the lithium ion battery and prolong the cycle life; and the preparation method has low requirements for raw materials and equipment, is easy to control the process, and is suitable for industrialized production.

Owner:BTR NEW MATERIAL GRP CO LTD

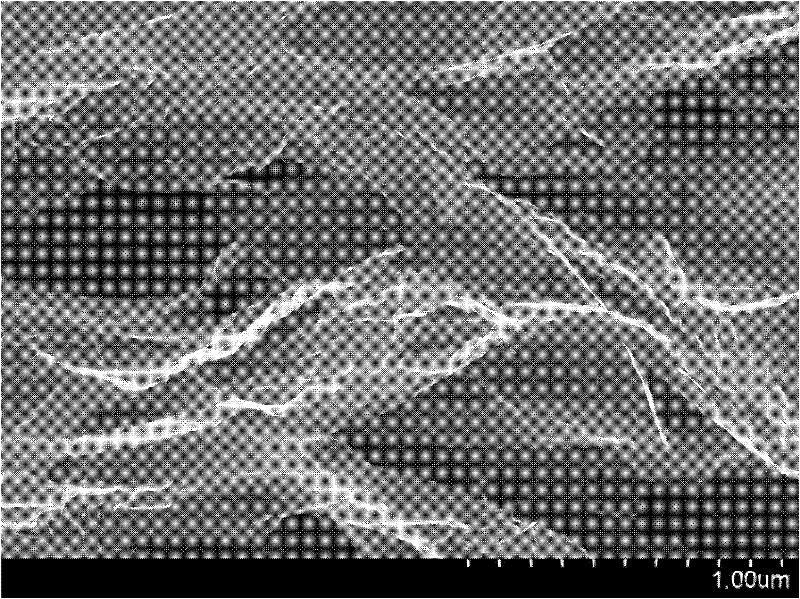

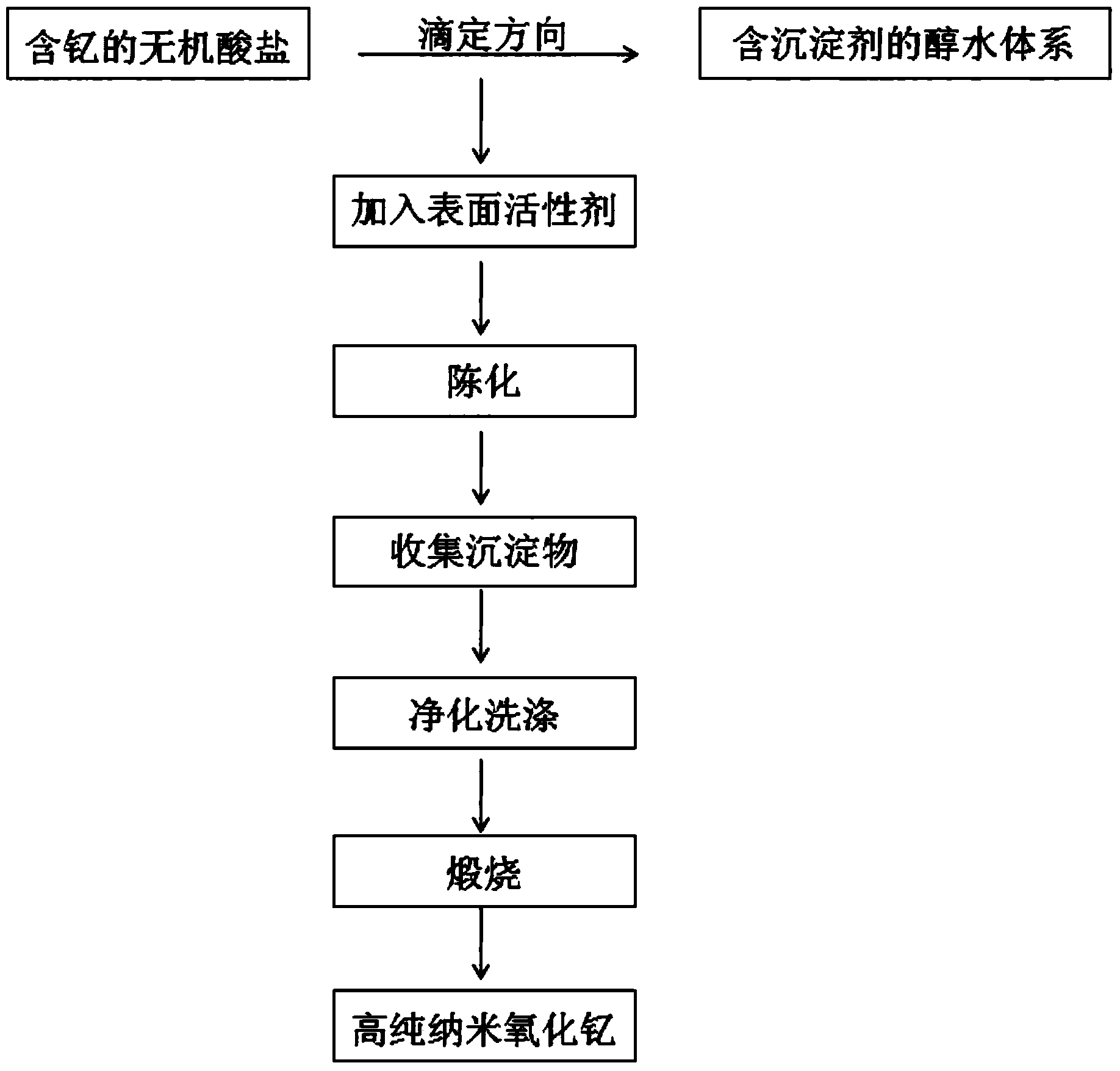

Preparation method for nanometer yttrium oxide powder

ActiveCN103539195ANarrow particle size distributionHigh sintering activityMaterial nanotechnologyRare earth metal compoundsRare earthBack titration

The invention discloses a preparation method for nanometer yttrium oxide powder, belonging to the technical field of preparing superfine rare earth powder. The method comprises the steps of dropping yttrium-containing inorganic acid salt in alcohol-water mixed solution which contains a precipitant and a static stabilizing agent, then adding a surfactant after finishing dropping, stirring, aging and separating the reaction system to obtain precipitate, then carrying out cleaning and washing, vacuum drying and calcinating to the precipitate to obtain the nanometer yttrium oxide powder. According to the preparation method, by applying the back titration, alcohol-water mixture solution and surfactant, not only can yttrium ions be favorably separated out and crystallized, but also the particle size of the crystals and the specific surface area of the crystal particles can be better controlled, so that the prepared nanometer yttrium oxide powder has smaller particle size, narrow particle size distribution and larger specific surface area, thus further having higher sintering activity; the preparation method is simple in technology, short in synthesis route, easy to control, capable of remarkably improving the purity and yield of products, and suitable for industrial production.

Owner:北京雷生强式科技有限责任公司

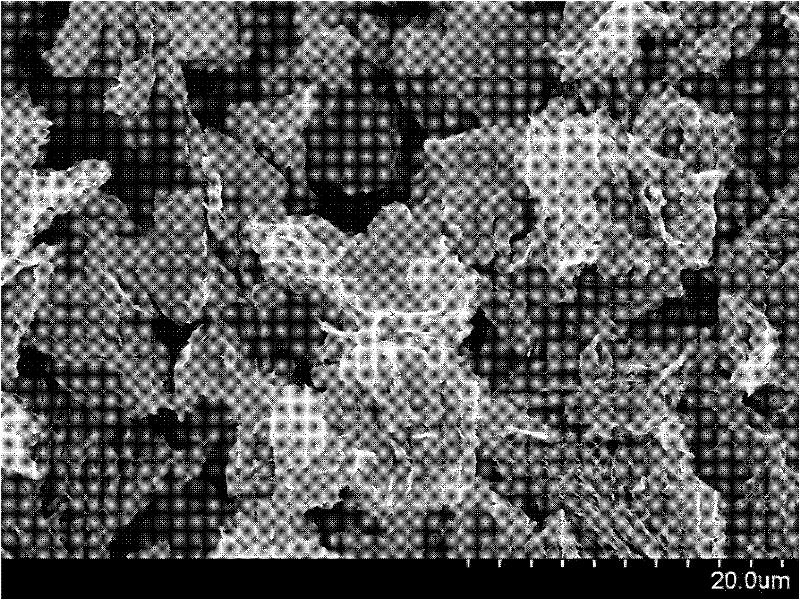

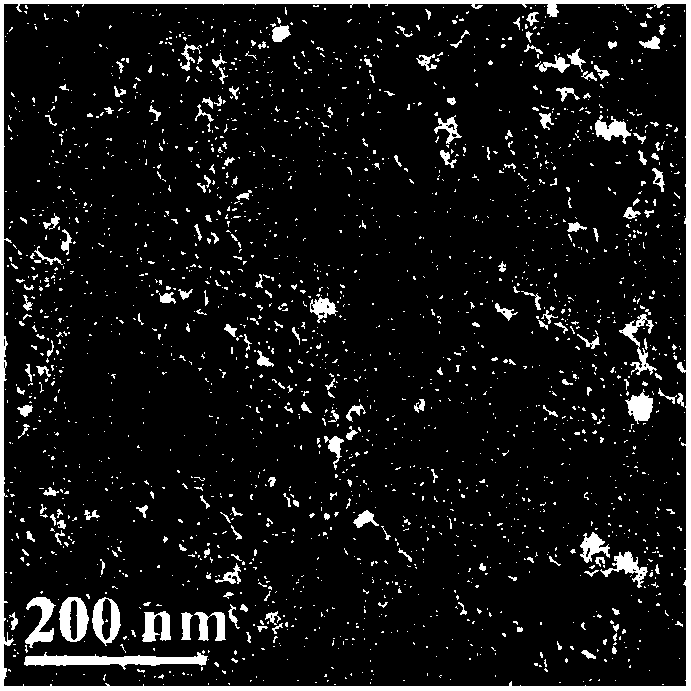

Preparation method of nano neodymium oxide with large specific surface area

InactiveCN106277021AImprove surface activityGood dispersionMaterial nanotechnologyRare earth metal compoundsInorganic saltsRare earth

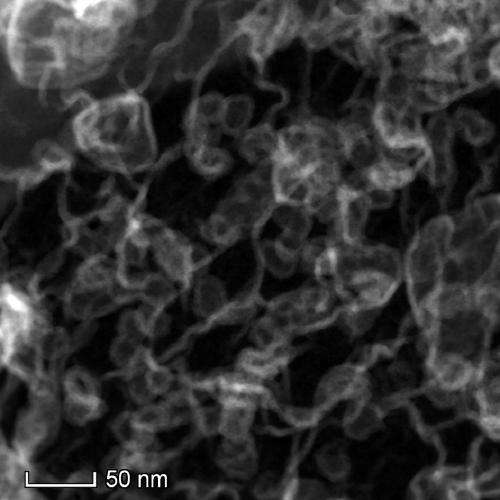

The invention belongs to the technical field of preparation of rare earth oxide and particularly relates to a preparation method of nano neodymium oxide with large specific surface area. The method comprises the following steps: adding a surfactant into a neodymium-containing inorganic salt solution; dropwise adding a precipitant into the solution, and stirring for sufficient reaction of the two solutions; aging to obtain a precipitate; and washing the precipitate with deionized water, and performing vacuum drying and ignition to obtain nano neodymium oxide with large specific surface area. In the invention, through the application of the surfactant and control of the precipitant concentration and dropwise adding speed, according to TEM detection, the primary particle size of the prepared nano neodymium oxide is 20-60nm, and the specific surface area is 60-100m<2> / g. The method provided by the invention has the advantages of simple technology, relatively low cost and high controllability, remarkably improves the product purity and yield, and is environment-friendly and suitable for industrial production.

Owner:常州卓煜新材料科技有限公司

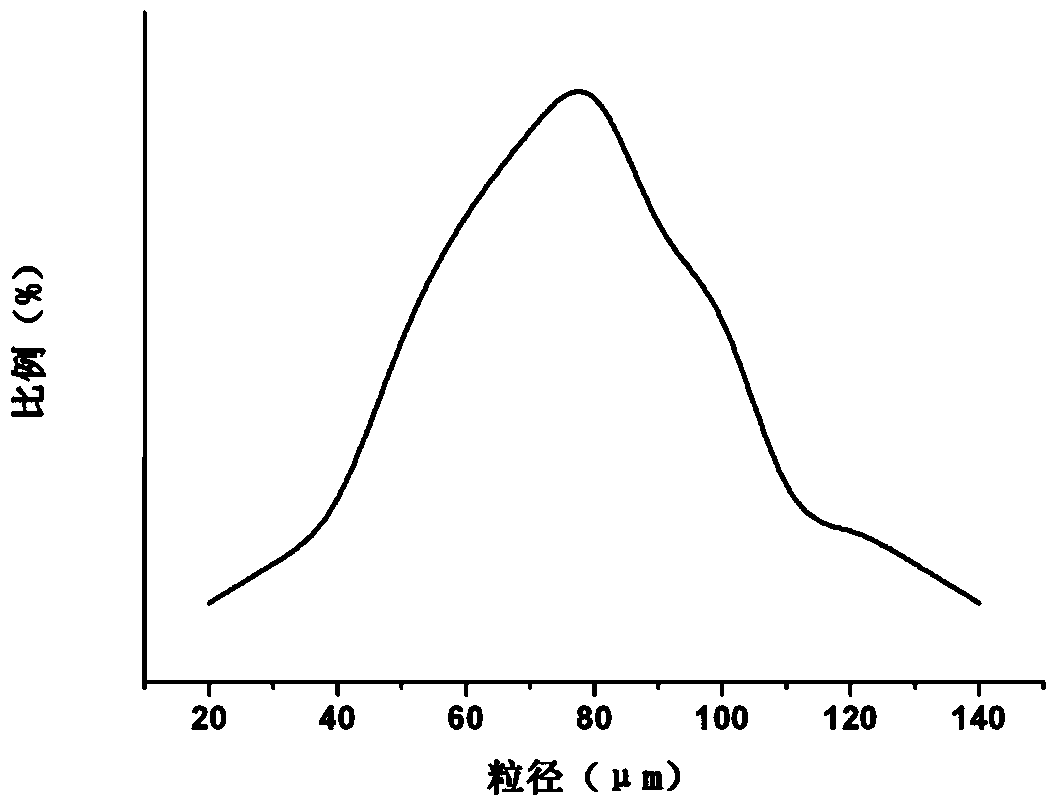

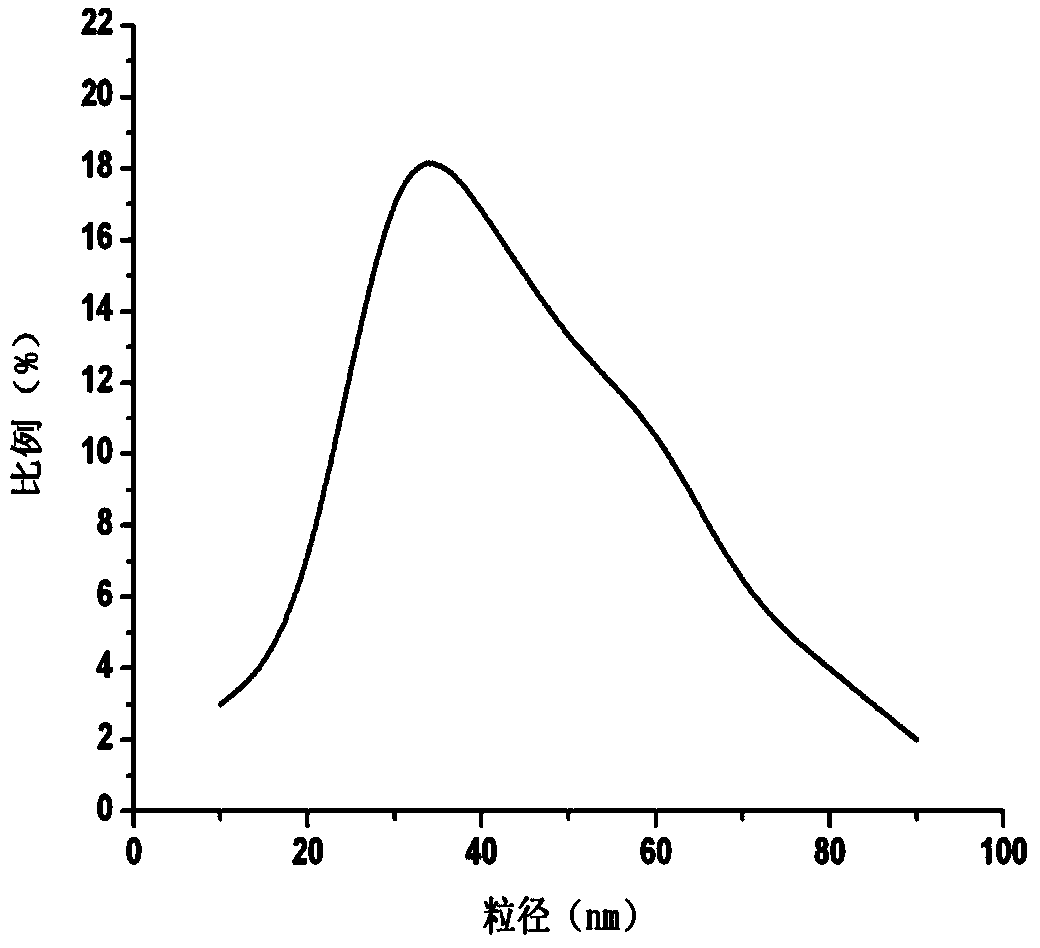

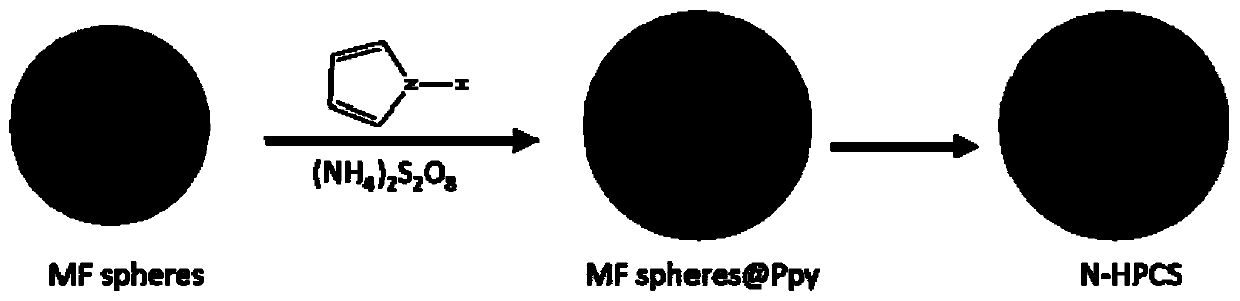

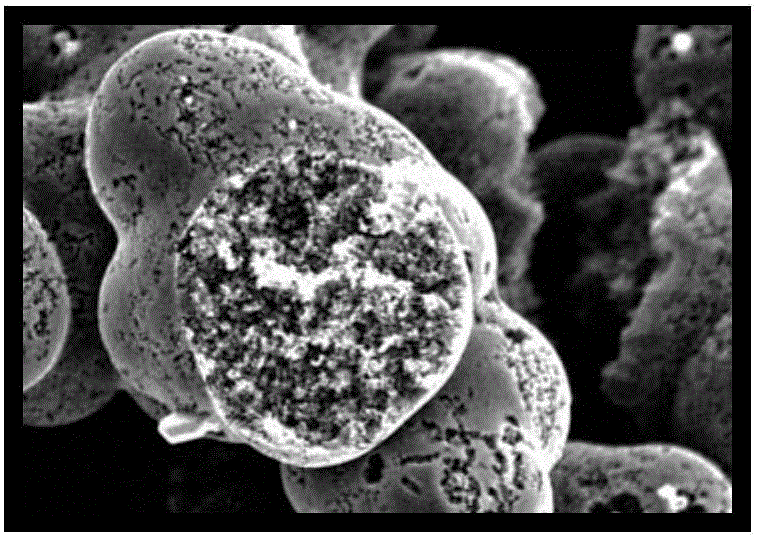

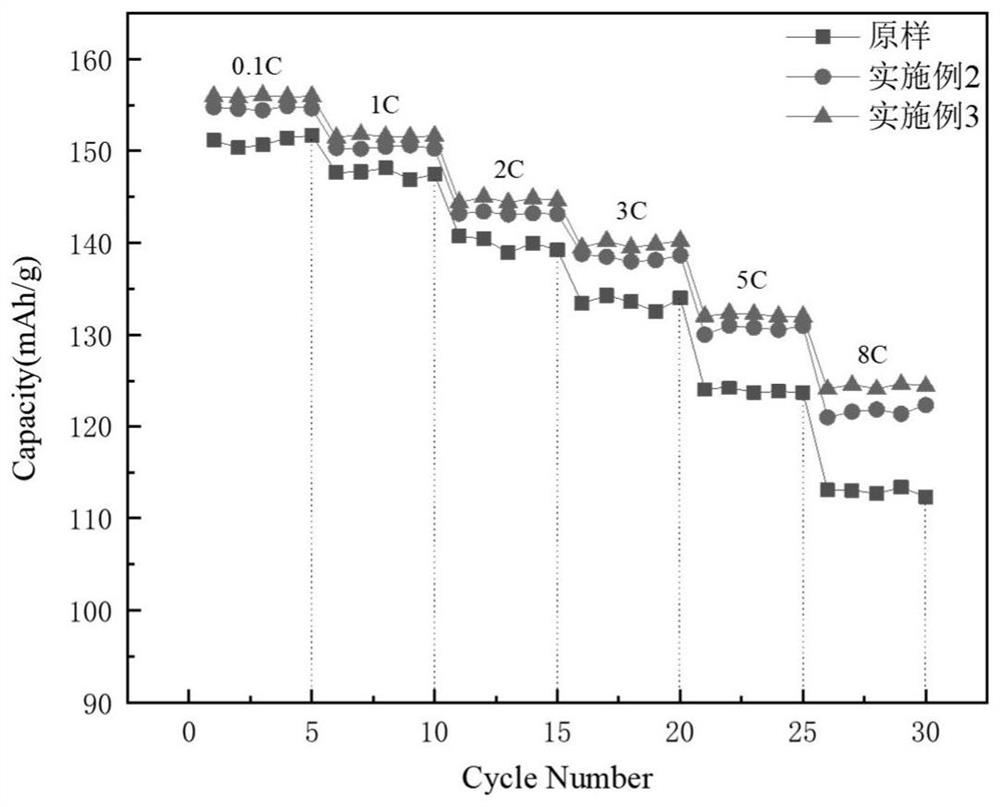

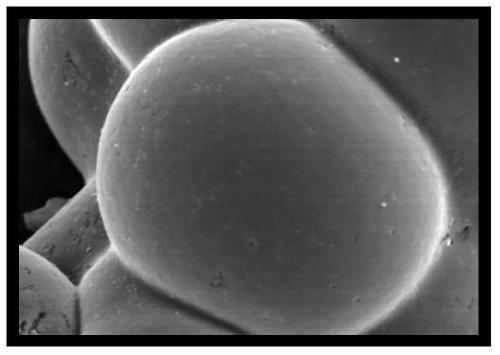

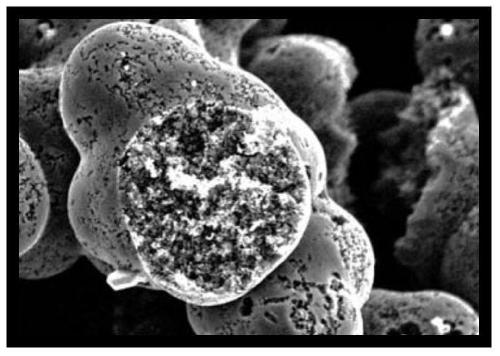

Nitrogen-doped porous hollow carbon sphere and preparation method and application thereof

PendingCN110729480AEliminate the etching stepFewer etch stepsSecondary cellsNegative electrodesPtru catalystPolypyrrole

Melamine resin pellets are obtained through one-step condensation of melamine and formaldehyde, the melamine resin pellets used as templates are coated with polypyrrole by using pyrrole as a nitrogensource and a carbon source and ammonium persulfate as a catalyst; the melamine resin pellets are gradually decomposed in the roasting process by controlling roasting to obtain nitrogen-doped porous hollow carbon spheres; and finally, the material is used in a lithium ion battery negative electrode. By using the melamine resin pellets instead of traditional silicon dioxide pellets, the problem of environmental pollution caused by etching of a silicon dioxide hard template with use of toxic reagents such as hydrofluoric acid in a traditional hard template method is avoided. Because the melamineresin pellets can generate a large amount of gas in the decomposition process, pores can be further formed in the pore walls of the hollow carbon spheres. Because the material is uniform in morphology, large in specific surface area and of a hollow structure, volume expansion can be relieved, and high specific capacity and cycle stability are shown in the lithium ion battery.

Owner:NANKAI UNIV

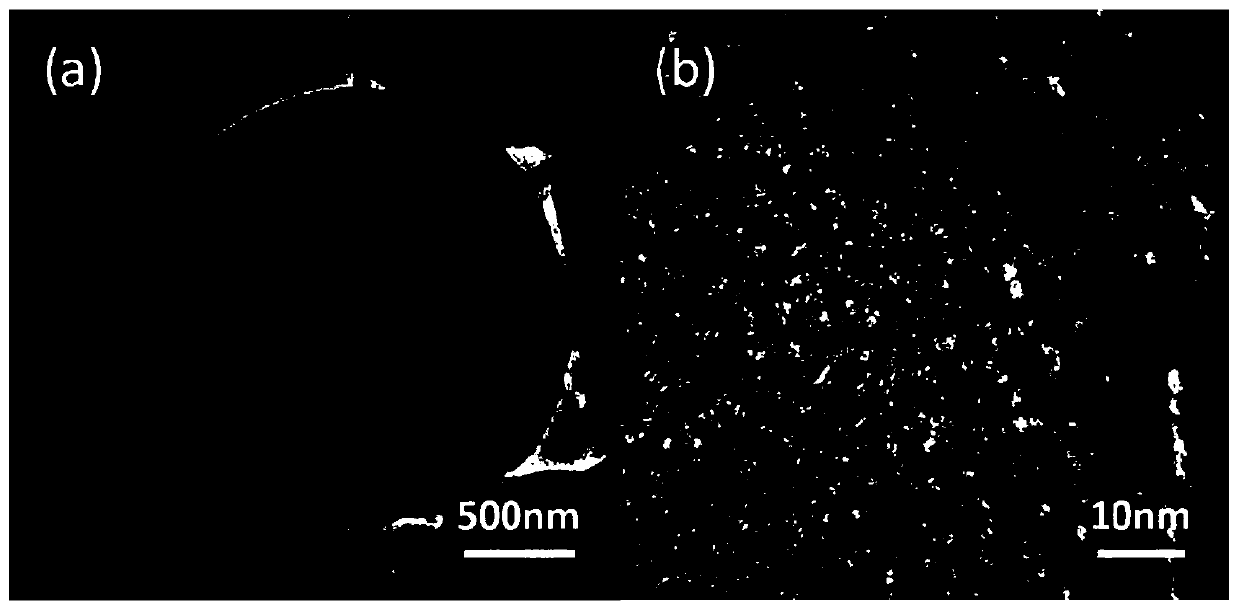

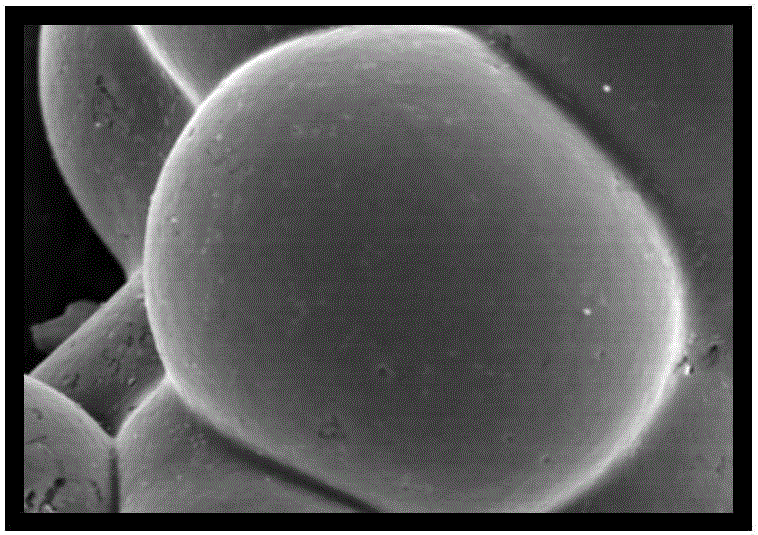

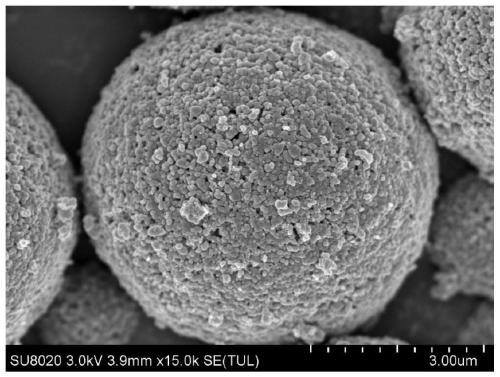

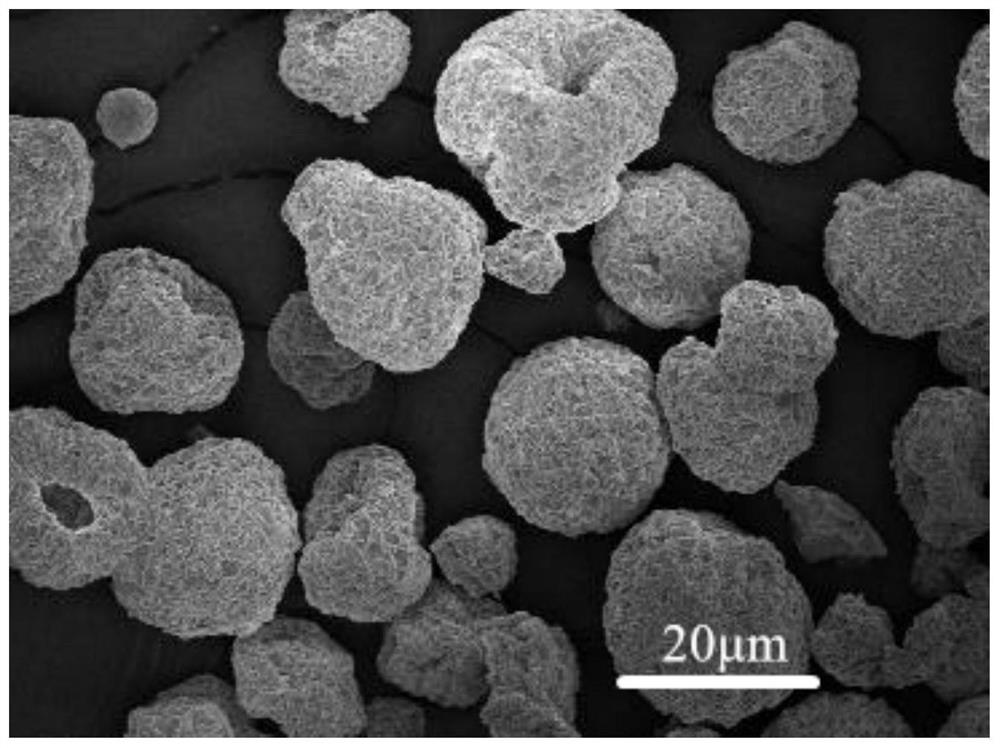

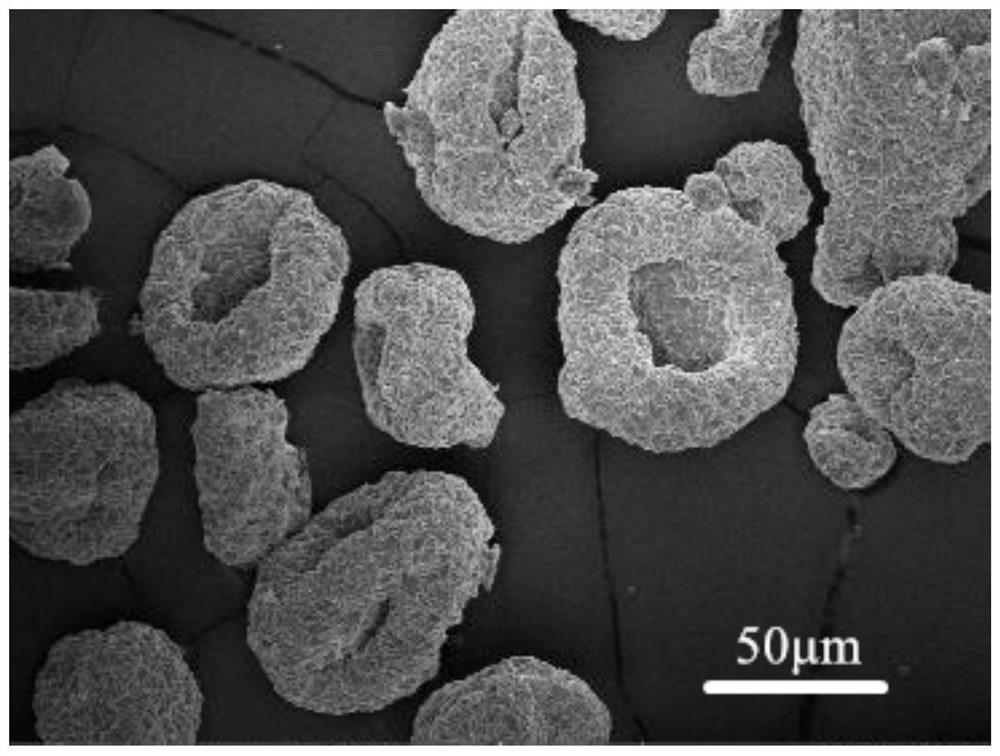

Preparation method of mesopore-controllable magnetic microsphere

InactiveCN101863517ASmall particle sizeControl specific surface areaFerroso-ferric oxidesMicrosphereMagnetic response

The invention belongs to the technical field of inorganic material preparation, relating to a preparation method of a mesopore-controllable magnetic microsphere. The preparation method comprises the following concrete steps: respectively adding soluble ferric ion salts, ammonium acetate and poly glutamic acid into ethylene glycol solution to obtain mixed solution; controlling clarification solution with the concentration of the ferric ion salts of 0.05-0.40mol / L, the concentration of the ammonium acetate of 0.50-4.00mol / L and the concentration of the poly (glutamic acid)of 2.50-50.00g / L in the mixed solution; placing the solution into a closed heating vessel, carrying out a solvent thermal reaction at 200-300DEG C and heating for 8-72 hours; and washing the obtained product with deionized water and drying at 40-80DEG C. The invention provides a novel simple and feasible preparation method capable of batch production. Meanwhile, the invention has the advantages of high magnetic response and specific area, easily-accessible raw materials, favorable repeatability in the preparation process and controllable grain size, specific surface area, pore volume and average pore size of the obtained microspheres.

Owner:FUDAN UNIV

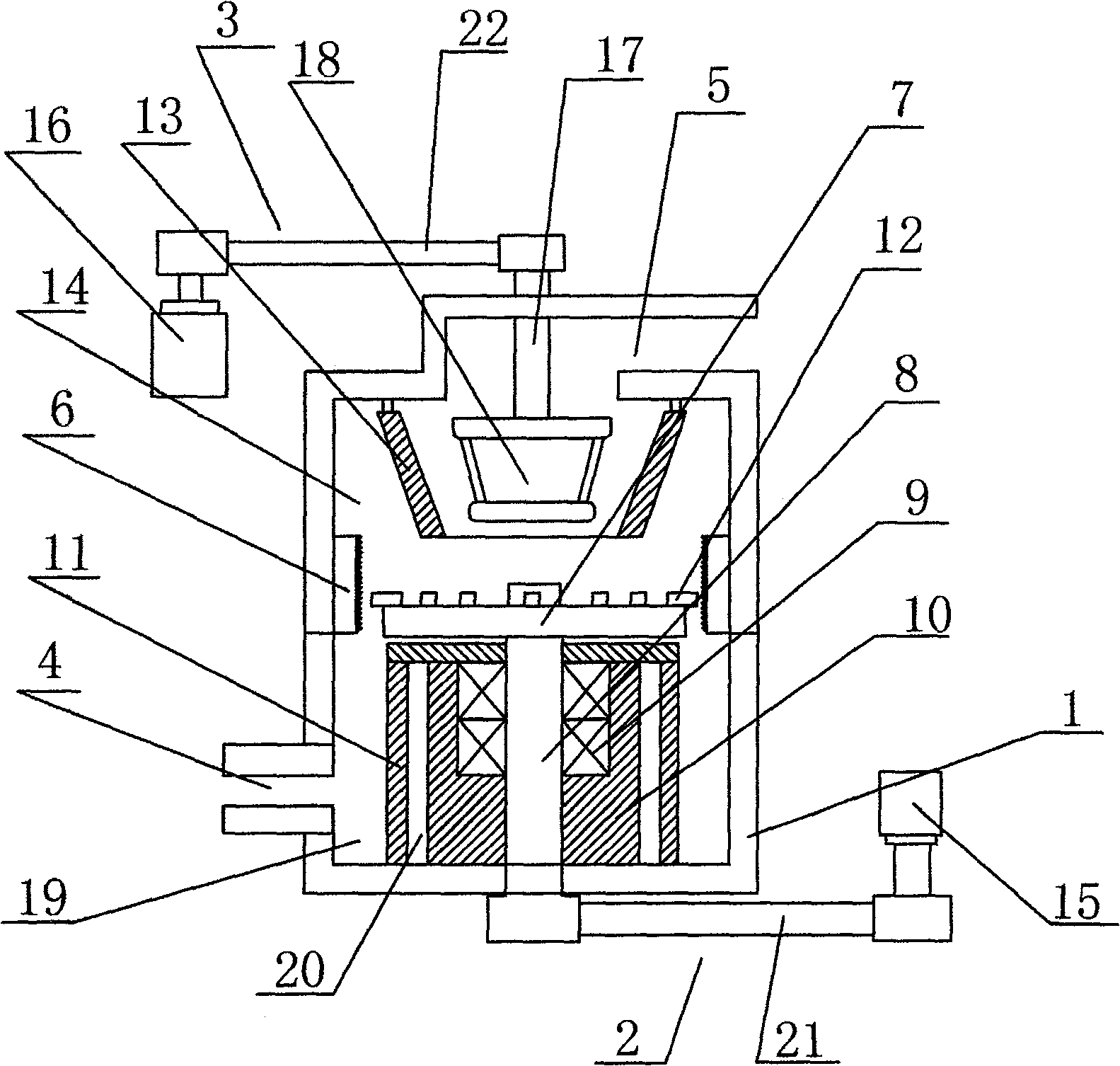

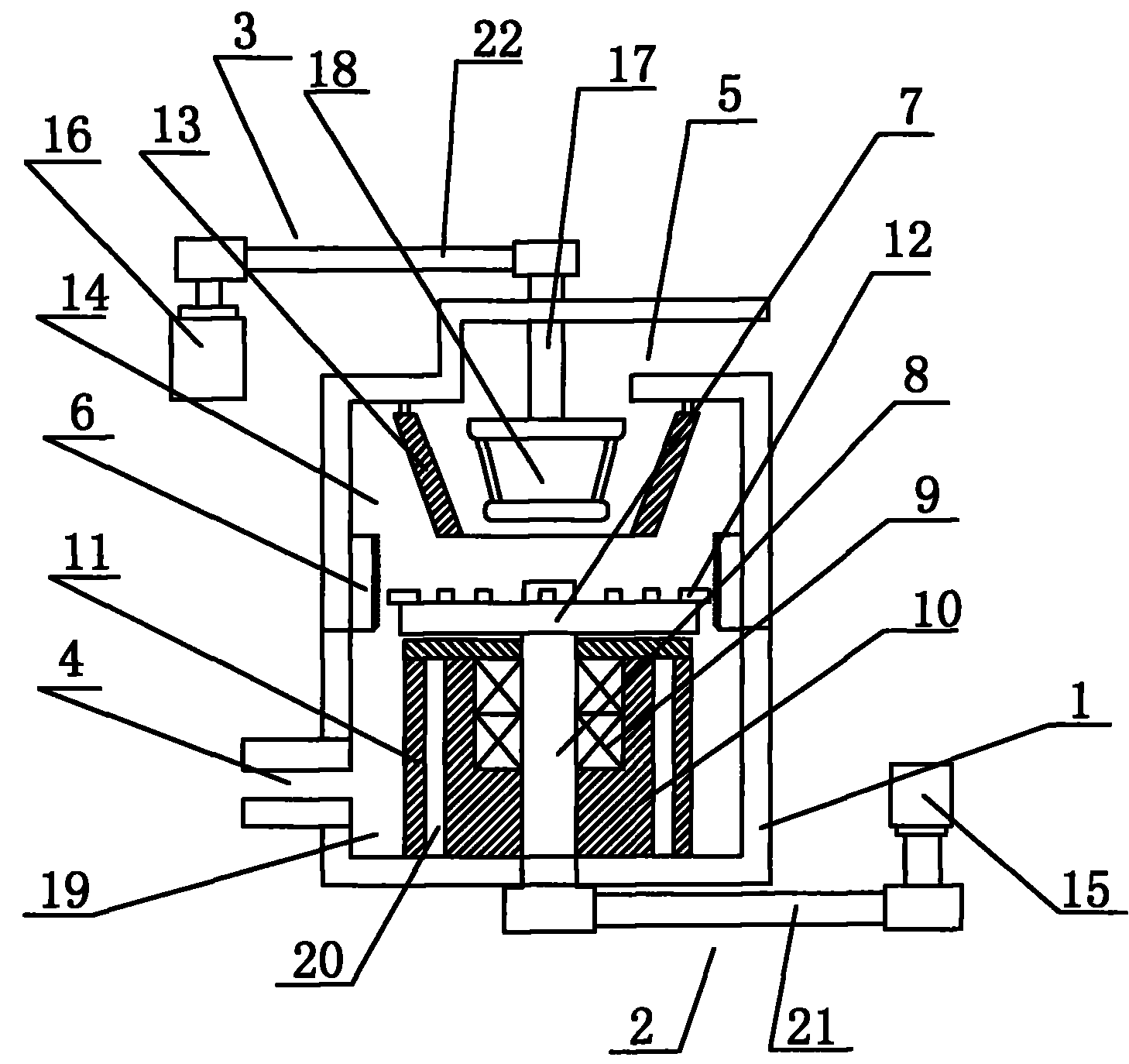

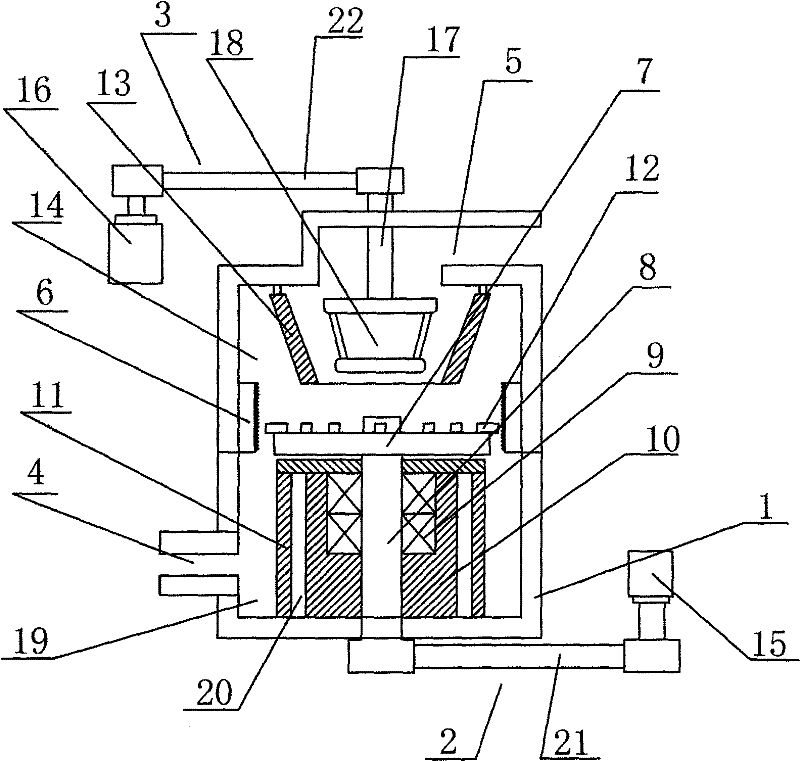

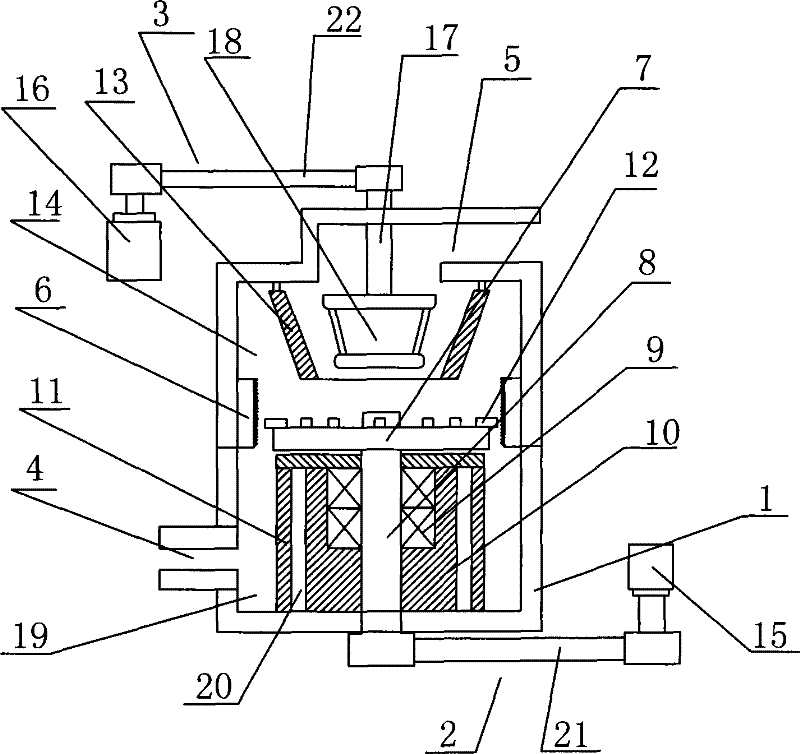

Air-flow vortex balling machine for producing spherical graphite

The invention discloses an air-flow vortex balling machine for producing spherical graphite, which consists of a machine body, a balling drive device and an internal classification machine drive device, wherein an internal classification machine, a powder balling module and a cooling system are arranged in the machine body. In the invention, an internal balling module and a classification module are rationally arranged, and thus, the air-flow vortex balling machine for producing the spherical graphite is provided. The air-flow vortex balling machine can ensure that the graphite powder undergoes the physical processes of thinning, shearing, collision, friction, coiling, uniting and densification in an air-flow vortex balling room or can realize the combination of a physical balling process and a mechanical powder thinning process to prepare the spherical product. The indexes, such as sphericity, grain fineness distribution, tap density, apparent density, actual density and special surface area, of the spherical graphite powder can be controlled in the range of pre-determined values; the quality is stable; the yield can be improved by over three times; and over 50 percent of energy consumption can be reduced.

Owner:LUOYANG GUANQI INDAL & TRADE

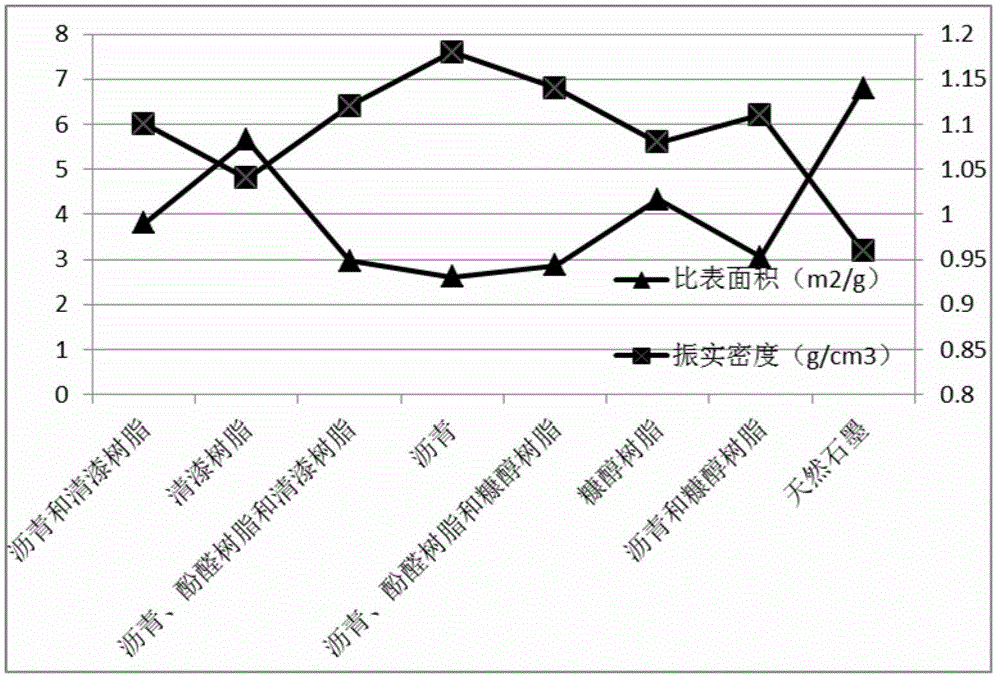

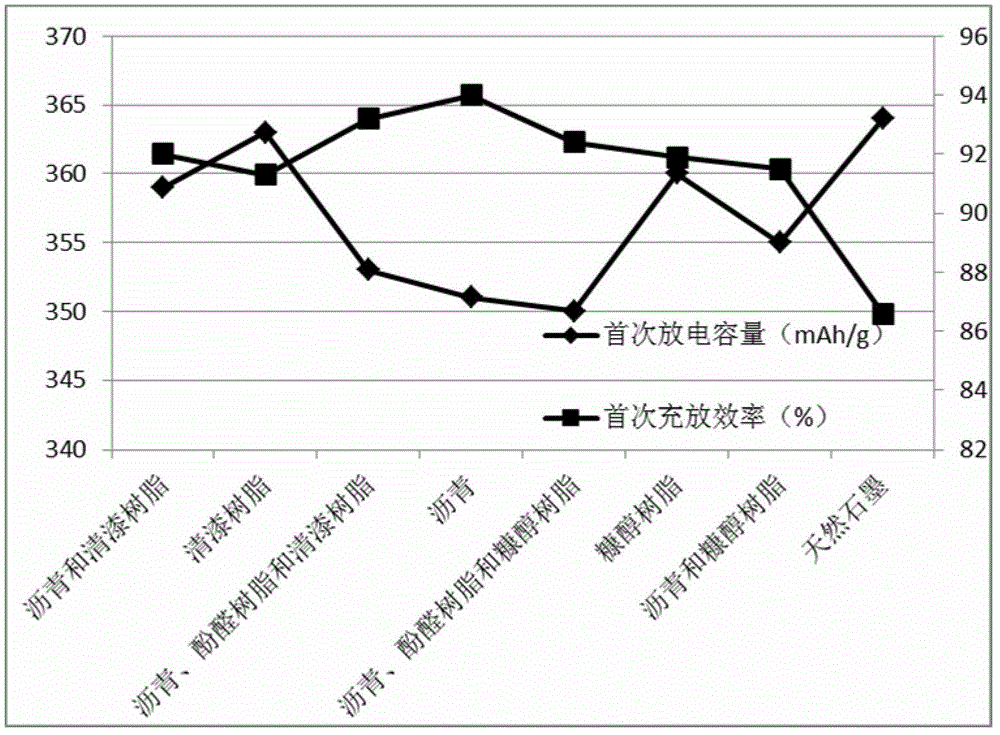

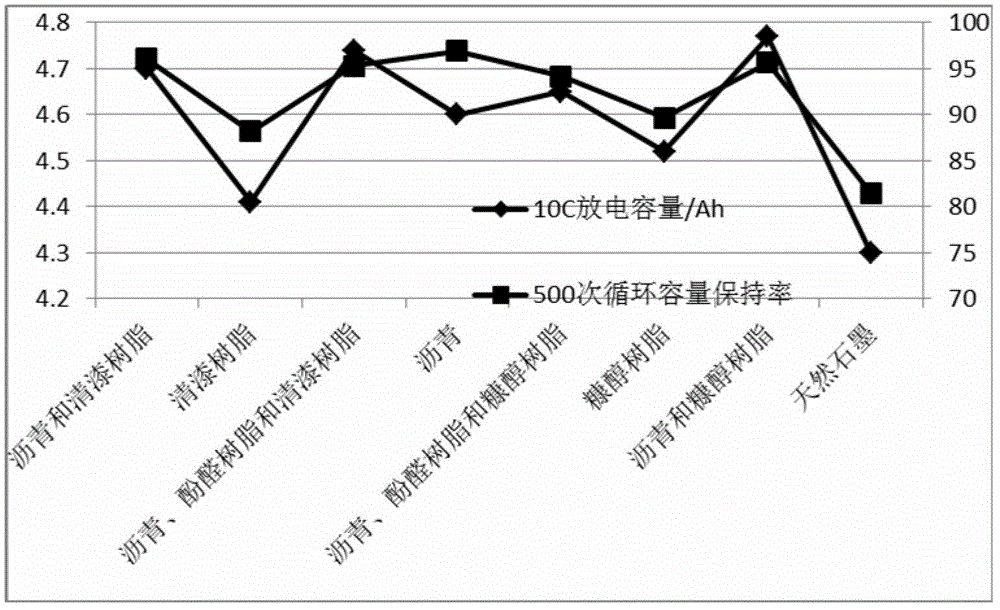

Method for improving electrical property of natural graphite

InactiveCN102910618AImprove electrical performanceControl specific surface areaGraphiteCell electrodesOperabilitySolvent

The invention relates to lithium ion battery cathode material natural graphite, in particular to a method for improving electrical property of natural graphite. The method is characterized by comprising the steps of firstly, adding solvent into a reactor, stirring, sequentially adding asphalt, polycondensate or organic mixture containing polycondensate, stirring, adding natural graphite, and evaporating solvent; secondly, drying and solidifying organic polymer coated on the surface of the graphite for 8-16 hours; thirdly, crushing obtained graphite particles; fourthly, performing hot treatment at 400-800 DEG C for 5-20 hours; fifthly, processing at 100-420 DEG C for 3 minutes to 25 hours; performing hot treatment at 800-1350 DEG C for 1-15 hours; and seventhly, crushing the graphite particles again until D50 particle size of the graphite particles ranges from 10 micrometers to 20 micrometers. By the method, uniformity and operability of polymer-coated graphite particles are improved, and comprehensive electrical property of the polymer-coated graphite particles is also improved.

Owner:IRICO

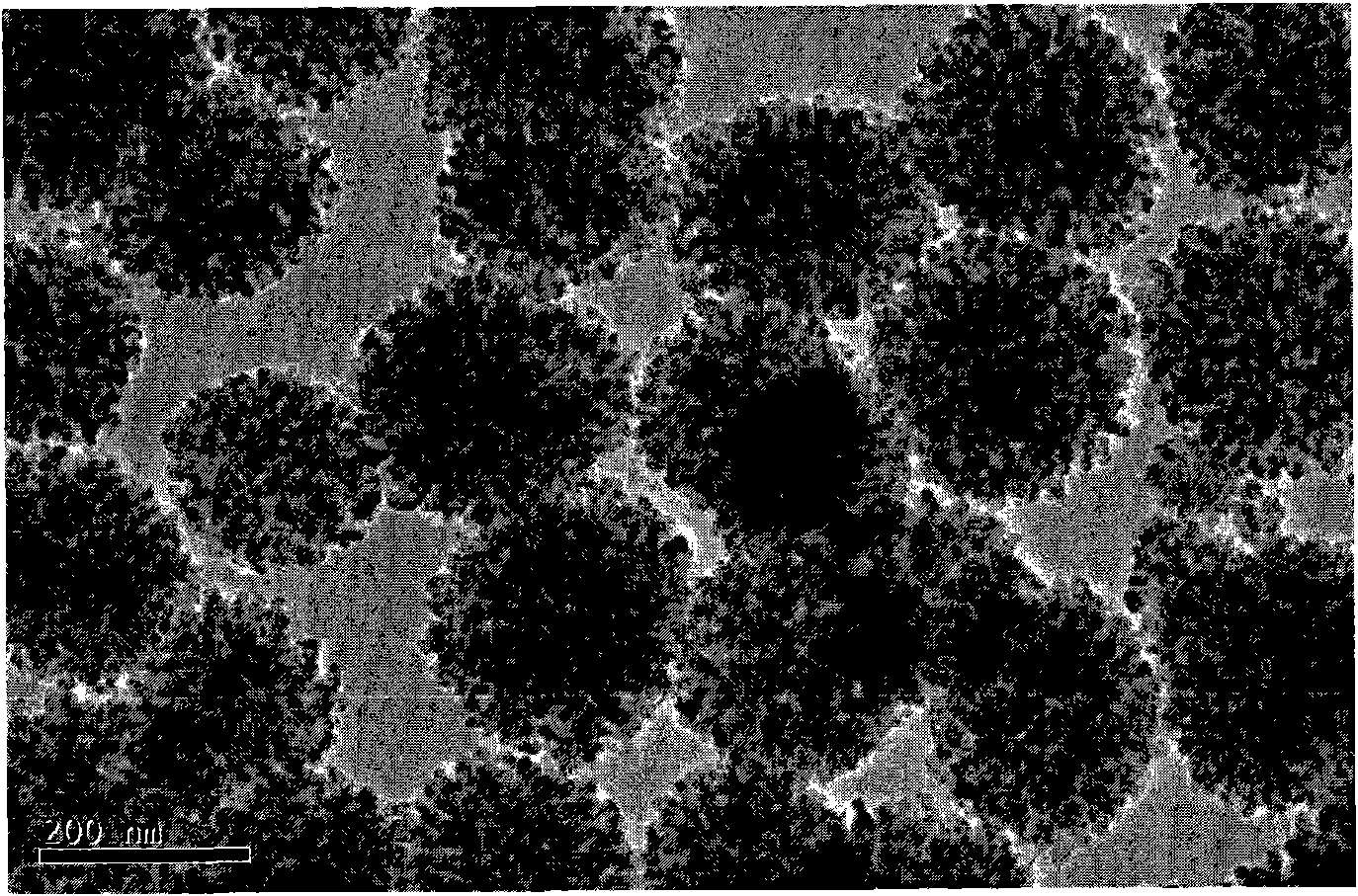

Copper-iron-carbon aerogel electrode preparation method

ActiveCN106467323AGood electro-Fenton catalytic activityWide variety of sourcesWater/sewage treatment using germicide/oligodynamic-processHigh activityGel electrode

The present invention relates to a copper-iron-carbon aerogel electrode preparation method. According to the method, resorcinol, formaldehyde, water, sodium carbonate, iron acetylacetonate and copper acetate monohydrate are uniformly mixed in a reaction container according to a certain ratio, a polymerization reaction is performed for a certain time at a certain temperature to prepare a wet gel, the wet gel is dried, programming heating and cooling is performed to prepare the copper-iron-carbon aerogel electrode, and the prepared copper-iron-carbon aerogel electrode is activated sequentially through CO2 and N2 so as to be used as the cathode in the degradation pool to degrade organic pollutants such as dimethyl phthalate and the like. Compared to the method in the prior art, the method of the present invention has advantages of simple preparation process, high activity, low treatment cost for degradation of organic pollutants such as DMP and the like, simple treatment process, flexible degradation, and the like.

Owner:TONGJI UNIV

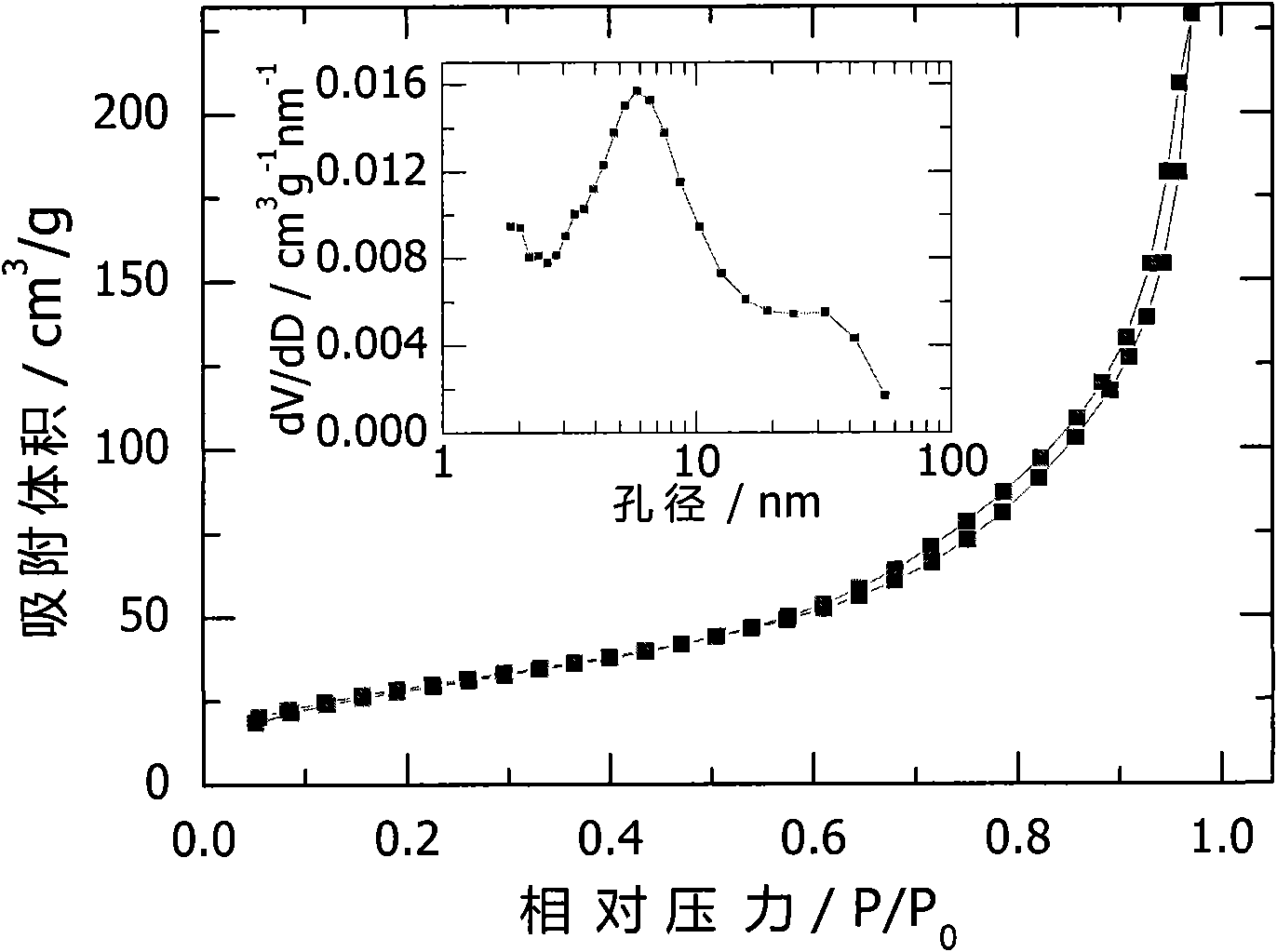

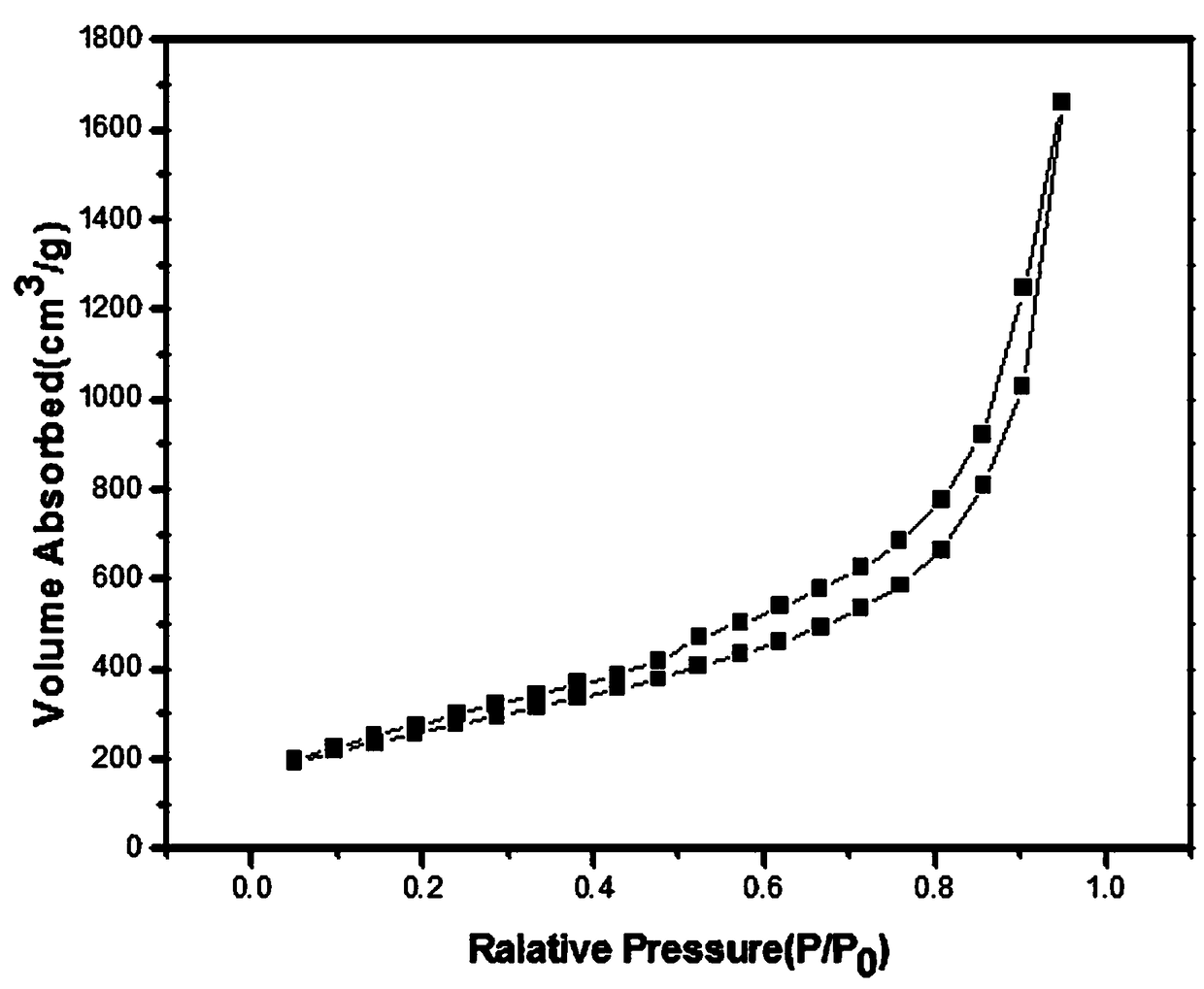

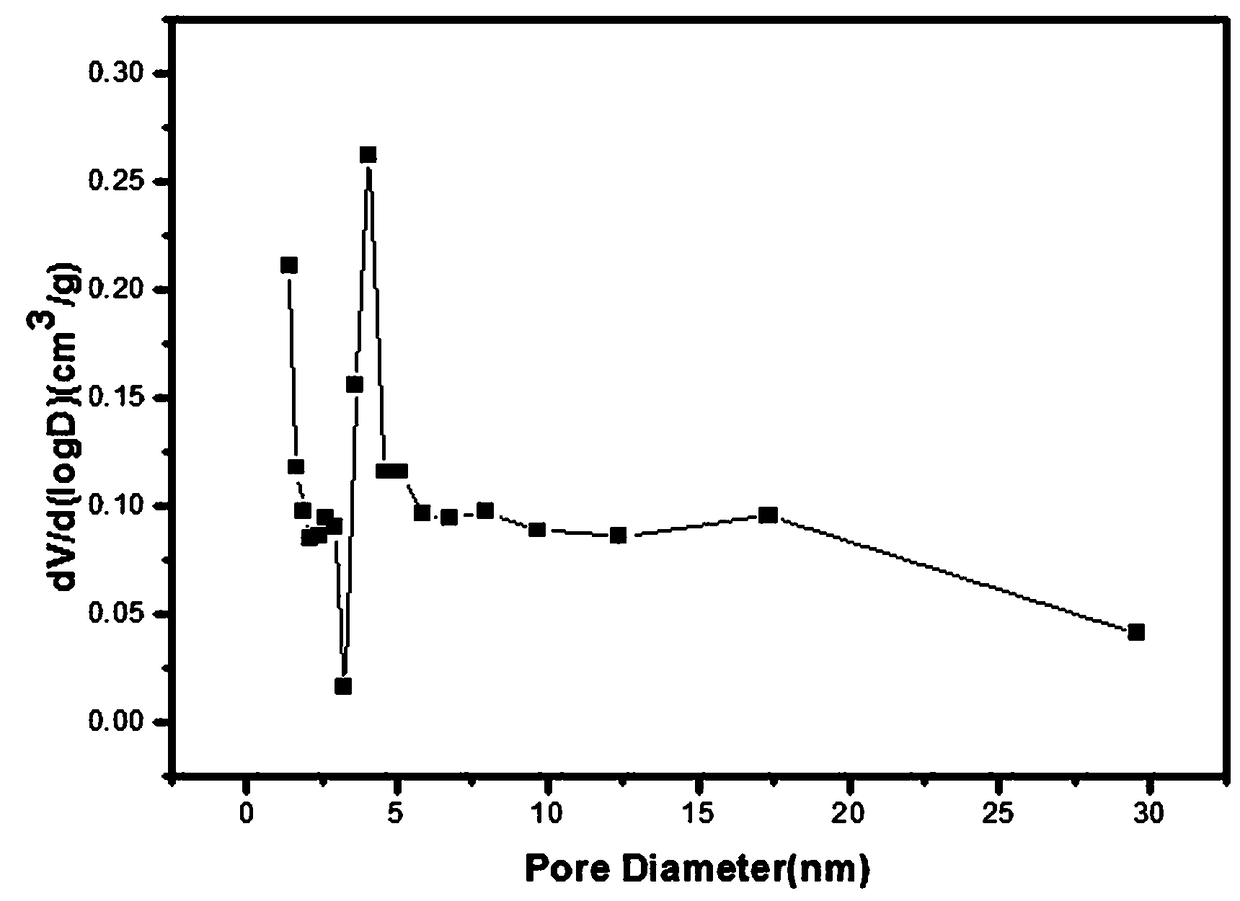

Fluorine and nitrogen co-doped three-dimensional graphene material and one-step carbonization preparation method thereof

The invention discloses a fluorine and nitrogen co-doped three-dimensional graphene material. The fluorine and nitrogen co-doped three-dimensional graphene material is prepared by taking polytetrafluoroethylene and melamine as precursors through mixing and uniformly grinding and carrying out a one-step carbonization method; fluorine and nitrogen elements of three-dimensional graphene are uniformlydistributed; the specific surface area is 1200 to 1400m<2>g<-1> and the total pore volume is 2.5 to 2.9cm<3>g<-1>; the specific surface area of the material can be greatly regulated and controlled tobe 50 to 1600m<2>g<-1> through changing the carbonization temperature and the total pore volume is regulated and controlled to be 0.2 to 3.2cm<3>g<-1>. The one-step carbonization preparation method comprises the following steps: 1, mixing the raw materials; 2, carrying out a one-step carbonization method. Three-dimensional graphene grids in the material are uniform, and the fluorine and nitrogenelements are uniformly distributed; the repeatability is good and the carbonization temperature is moderate; the material is synthesized through one-step carbonization and a technology is simple and easy to operate. The material has a wide application prospect in the field of super-capacitors and a carbon functional material.

Owner:GUILIN UNIV OF ELECTRONIC TECH

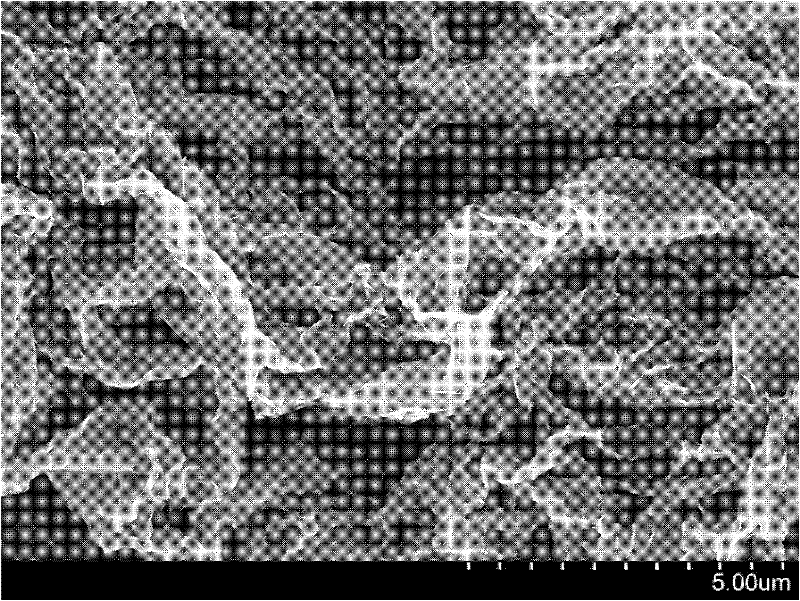

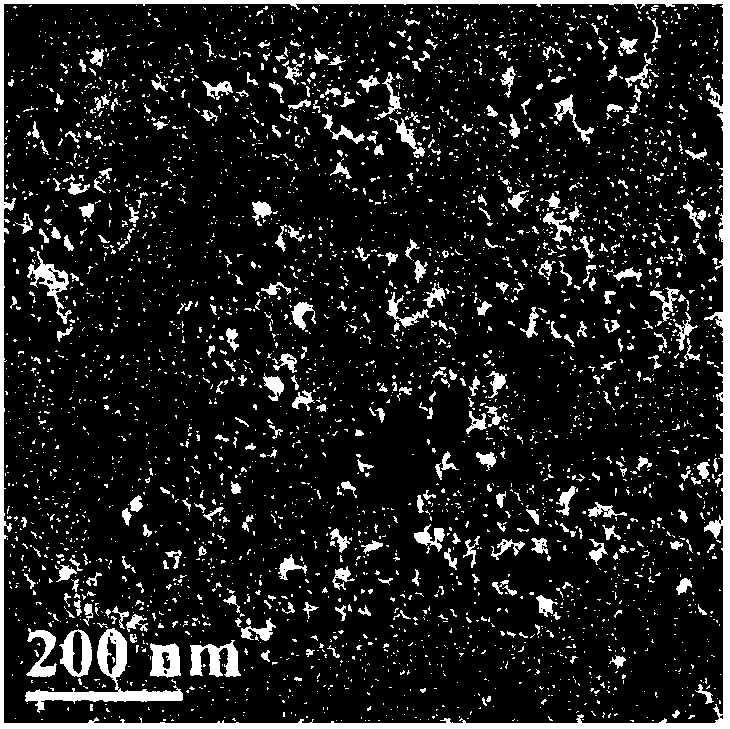

Method for preparing nanometer erbium oxide by reaction ball milling method

ActiveCN108264080AWell mixedFully contactedRare earth metal oxides/hydroxidesMaterial nanotechnologyAlcoholGraphene

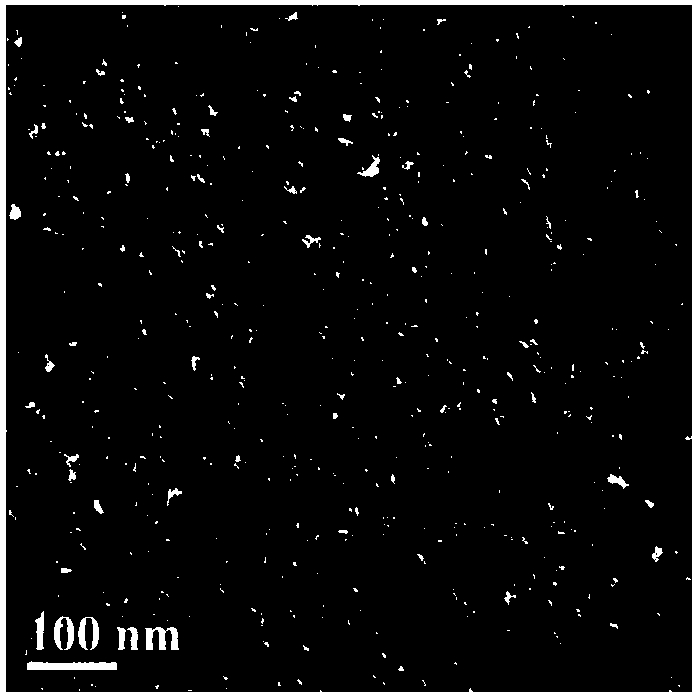

The invention discloses a method for preparing nanometer erbium oxide by a reaction ball milling method. The method comprises the following steps of simultaneously putting erbium-containing inorganicsalt water solution, graphene oxide-containing alcoholic solution, surfactants, precipitants and grinding body zirconium oxide beads into a ball milling cavity; taking a reaction on various raw materials under the ball milling effect; forming a nanometer erbium oxide precursor; performing filtering, washing, drying and roasting to obtain high-purity high-dispersion nanometer erbium oxide. Throughthe application of the reaction ball milling method, the graphene oxide-containing alcoholic solution and the surfactants, the prepared nanometer erbium oxide has the primary particle diameter of 10 to 30 nm through TEM detection. The method has the advantages that the process is simple; the cost is low; the controllability is high; the product particle uniformity is obviously improved; no pollution is caused on the environment; the method is suitable for industrial production.

Owner:CHANGZHOU GEOQUIN NANO NEW MATERIALS

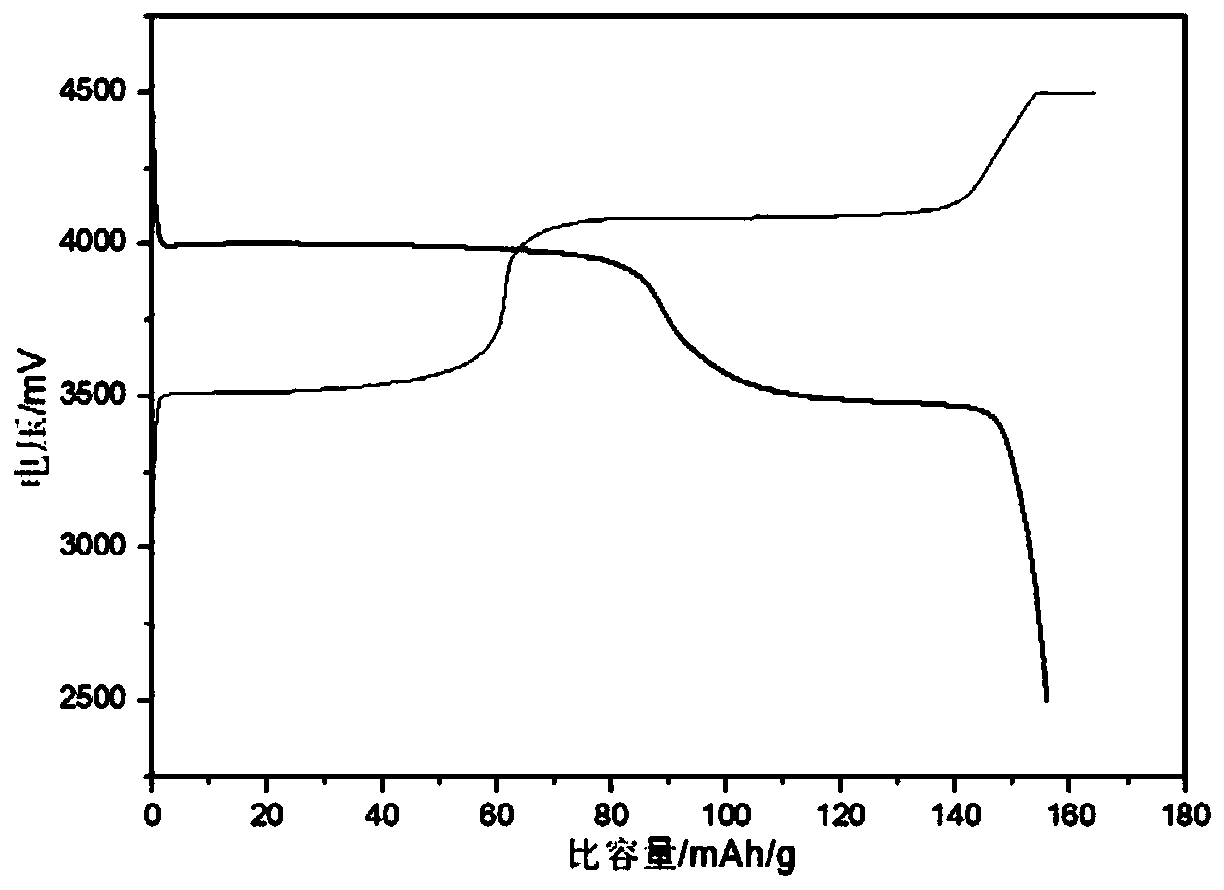

Lithium ferromanganese phosphate/carbon coated ternary material and preparation method thereof, lithium ion battery positive electrode and lithium ion battery

ActiveCN111370697ACoating method is simple and easy to operateReduce side effects from direct contactSecondary cellsPositive electrodesCarbon sourceLithium electrode

The invention discloses a lithium iron manganese phosphate / carbon-coated ternary material and a preparation method thereof, a lithium ion battery positive electrode and a lithium ion battery. The method comprises the following steps: 1) carrying out first ball milling on Fe2O3, Mn3O4, LiH2PO4 and a first organic carbon source, and carrying out first drying to obtain a precursor 1; 2) placing the precursor 1 in an air atmosphere, and carrying out heat treatment to obtain a precursor 2; 3) carrying out second ball milling on the precursor 2 and a second organic carbon source, and carrying out second drying to obtain a precursor 3; 4) sintering the precursor 3 at a constant temperature under the protection of an inert atmosphere to obtain a LiMn(1-x)FexPO4 / C composite material; 5) dispersingthe LiMn(1-x)FexPO4 / C composite material, a binder and a conductive agent in an oil solvent to prepare slurry, and 6) coating the surface of an electrode sheet prepared from a ternary material with the slurry, and drying The preparation method is simple and easy to operate, low in cost and excellent in product electrical property.

Owner:沁新集团(天津)新能源技术研究院有限公司

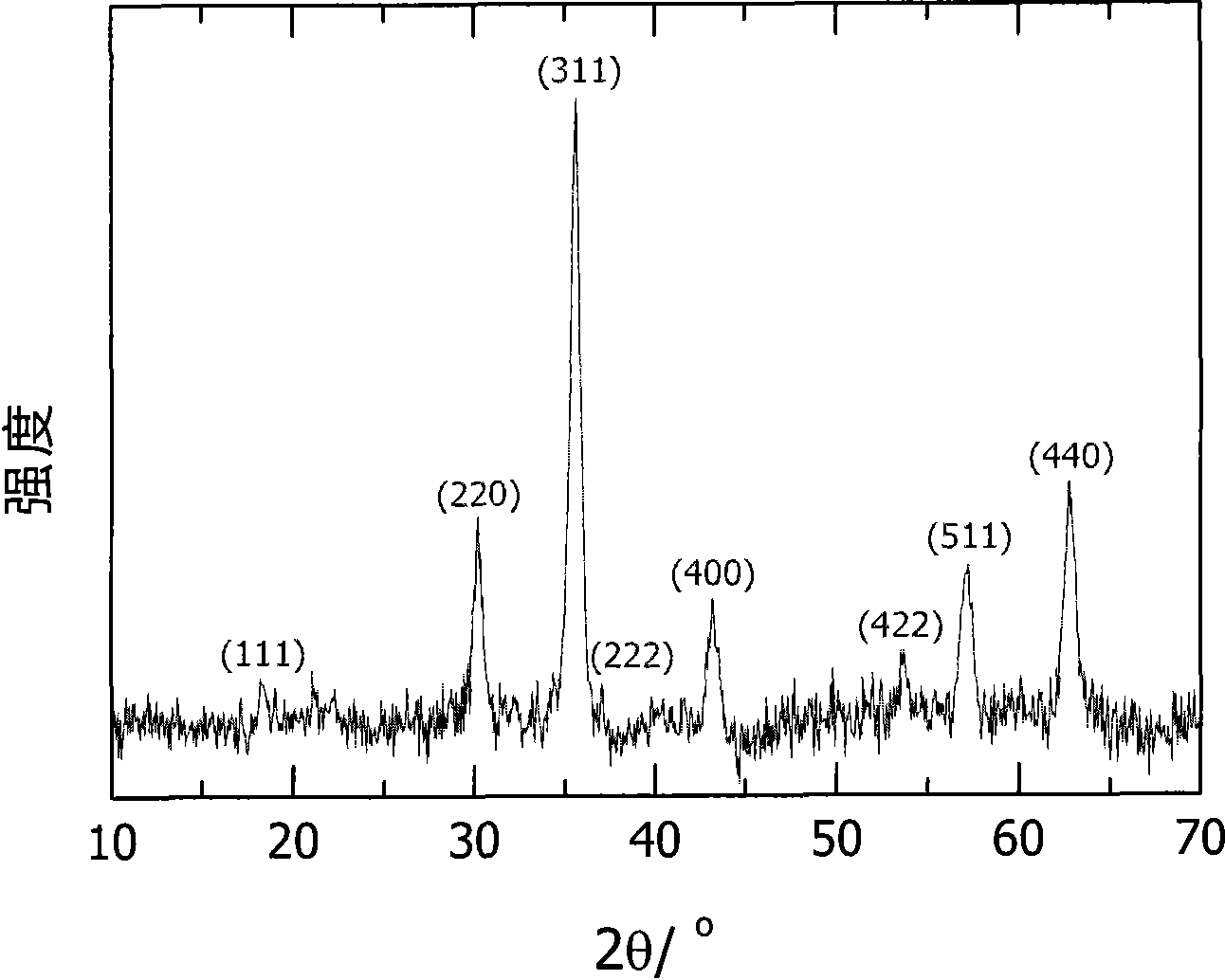

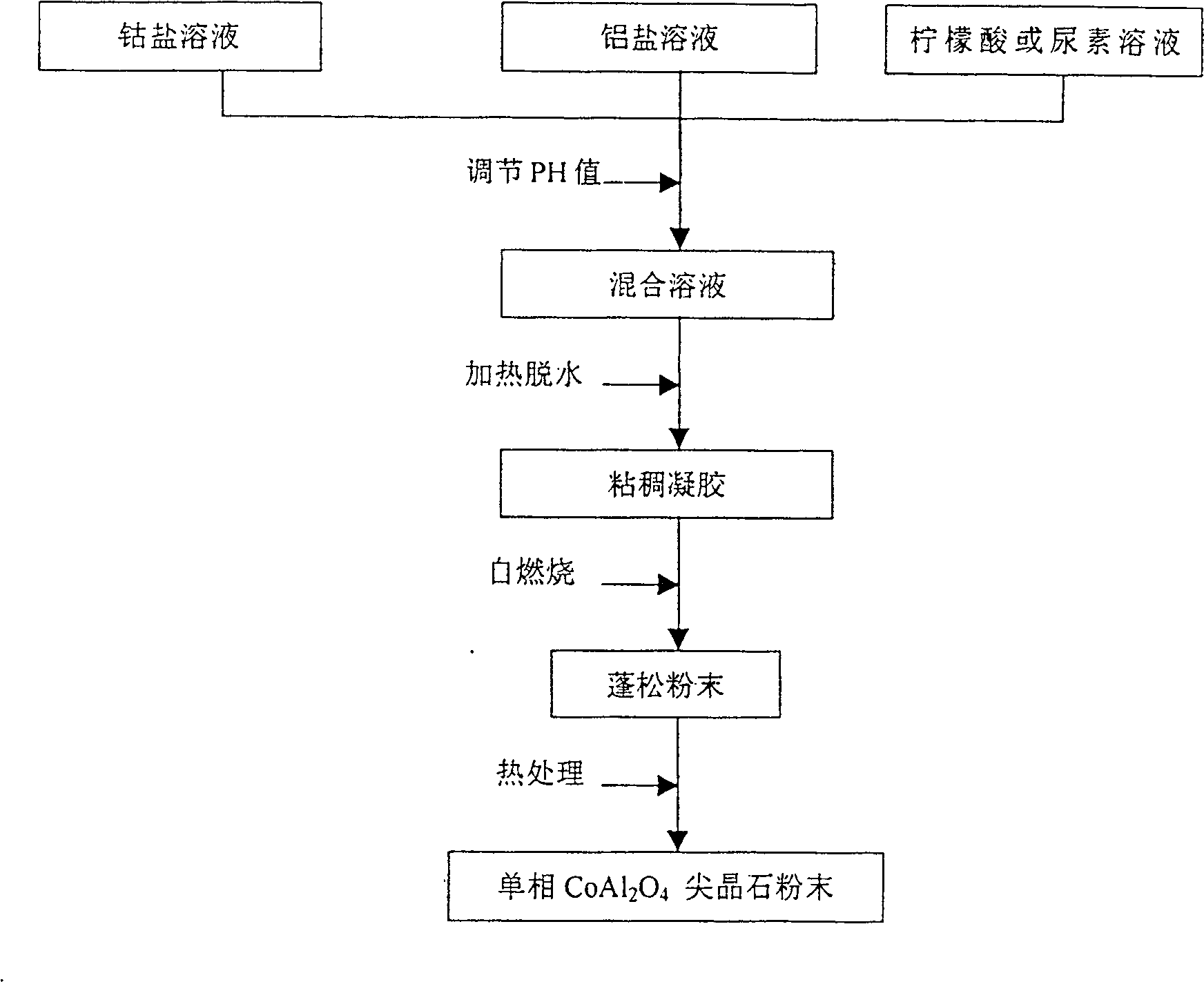

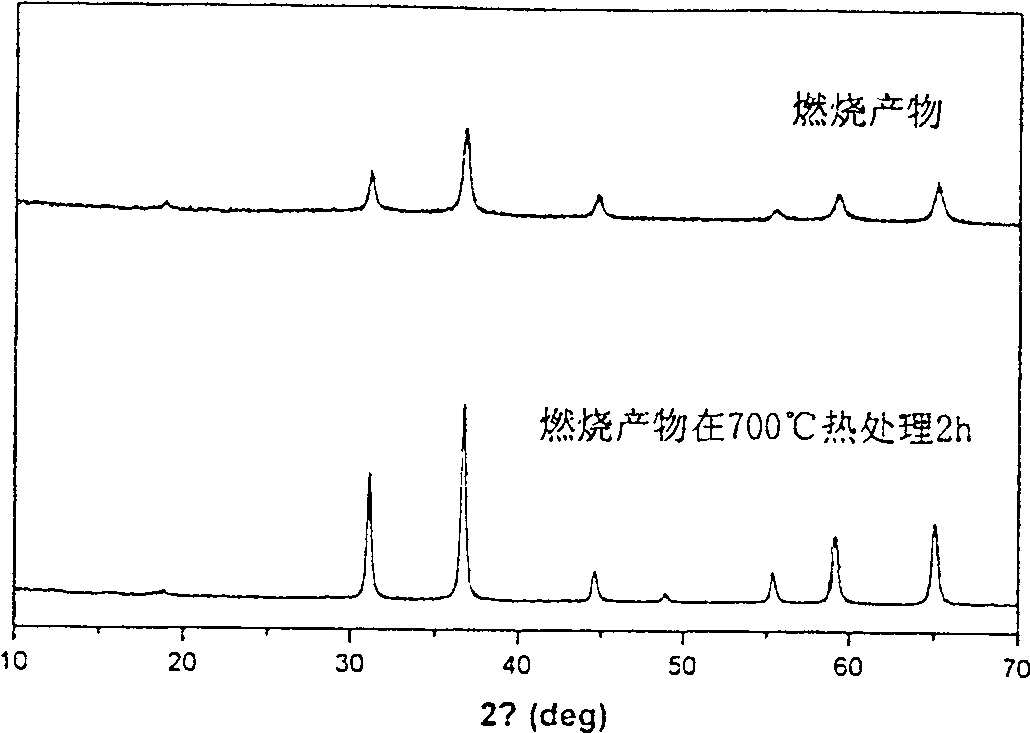

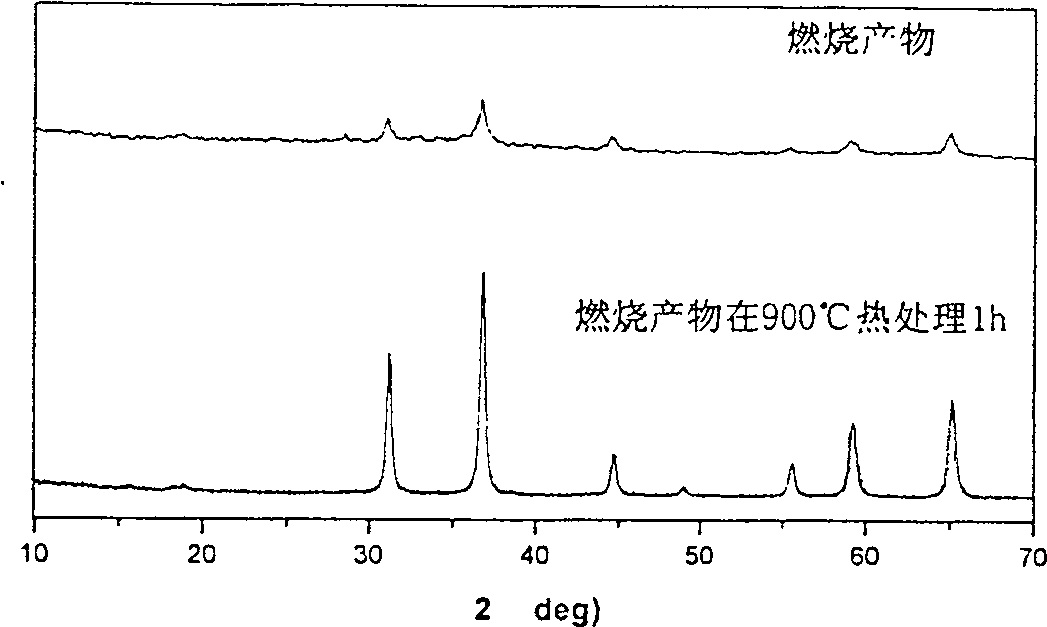

Synthesizing nano crystal cobalt aluminium spinelle pigment by using solution combustion method

InactiveCN100523094CSimple equipmentThe reaction process is simplePigment physical treatmentUreaAluminium salts

The invention discloses a method for preparing nanocrystalline cobalt-aluminum spinel (CoAl2O4) pigments through low-temperature combustion, which belongs to the field of nanocrystalline pigment preparation. The present invention is with soluble aluminum salt (aluminum nitrate, aluminum acetate, aluminum sulfate), soluble cobalt salt (cobalt nitrate, cobalt acetate, cobalt sulfate), citric acid or urea as starting material, Co2+: Al3+: citric acid three The mixing molar ratio is 1:(2-3):(1-6), or the mixing molar ratio of Co2+:Al3+:urea is 1:(2-3):(3-15). The solutions are mixed to form a complex, and citric acid or urea is used as a complexing agent and also as a fuel. The mixed solution is ignited by electric heating or microwave heating to obtain a fluffy powder, and then heat-treated at 500-1000°C to obtain nanocrystalline CoAl2O4 with a particle size of 10-100nm. The present invention is characterized in that the technological process is simple and efficient, and the combustion process is completed within 15 minutes. The process is low in energy consumption, easy to operate, and suitable for large-scale industrial production.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

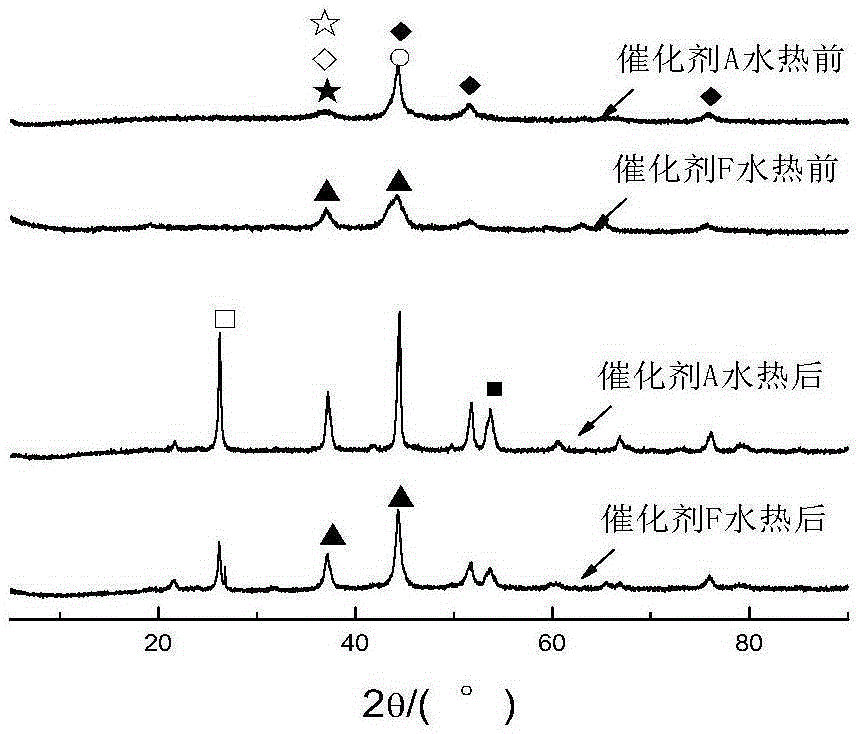

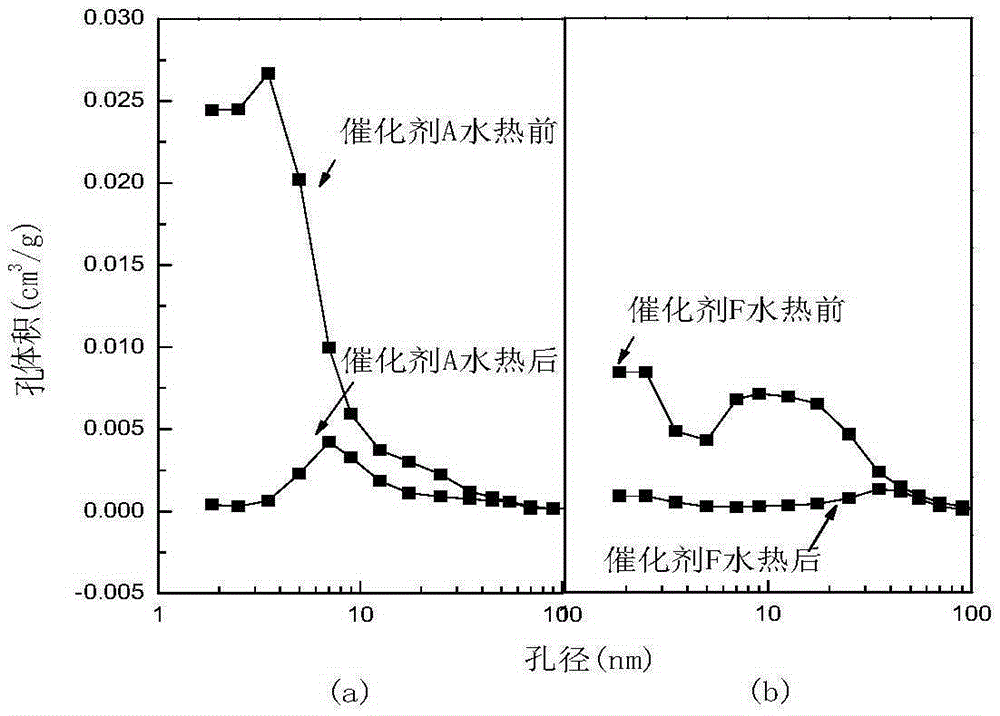

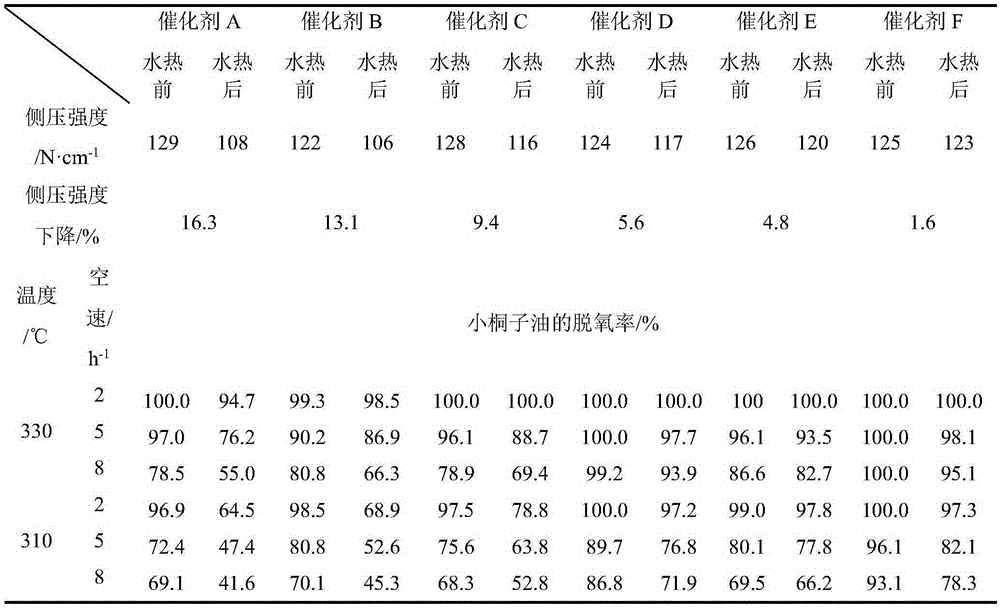

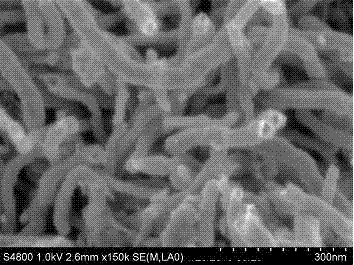

Preparation method of hydrodeoxygenation catalyst with high hydrothermal/mechanical stability

ActiveCN105396597AImprove mechanical stabilityHigh hydrothermal/mechanical stabilityMolecular sieve catalystsLiquid hydrocarbon mixture productionMolecular sieveMechanical stability

The invention discloses a preparation method of a hydrodeoxygenation catalyst with high hydrothermal / mechanical stability. The preparation method comprises the following steps: (1) preparing MoNi composite oxide powder; and (2) preparing a bulk type MoNi composite oxide catalyst, namely uniformly mixing the MoNi composite oxide powder, a binder and powder of sesbaria cannabina, dropwise adding 3% dilute nitric acid, performing strip extrusion for forming, and roasting for 2-5h in a muffle furnace at the temperature being 400-800 DEG C to obtain the bulk type MoNi composite oxide catalyst, wherein the binder is selected from two or more of magnesium aluminate spinel, kieselguhr and a molecular sieve binder. In the forming process of the catalyst, the binder is prepared from a material having relatively high hydrothermal resistance and mechanical stability, so that the bulk type MoNi composite oxide hydrodeoxygenation catalyst having high hydrothermal / mechanical stability, and activity is obtained, the edgewise comprehensive strength of the bulk type catalyst can be up to 90-140N / cm, and the hydrothermal / mechanical stability of the prepared catalyst can be obviously improved.

Owner:HEBEI UNIV OF TECH

Preparation method and application method of photo catalyst for high-efficiency photo-catalytic propylene epoxidation material

InactiveCN107051580AHigh catalytic activitySimple preparation processOrganic chemistryMolecular sieve catalystsGeneration ratePhotocatalytic reaction

The invention relates to a preparation method and an application method of a photo catalyst for a high-efficiency photo-catalytic propylene epoxidation material. The preparation method comprises the following processes: preparing a titanium silicon molecular sieve TS-1 carrier by adopting a hydrothermal method and directly supporting Au and Ag bimetals on the carrier by utilizing an impregnation-reduction method to prepare a bimetallic-supported Au-Ag / TS-1 photocatalyst. The prepared photocatalyst is put in a fixed bed reactor; propylene, oxygen and diluent gas are introduced; photo-catalytic reaction is performed by taking a 100W ultraviolet mercury lamp as a light source to prepare propylene epoxide PO. The propylene can be efficiently and highly-selectively converted into the propylene epoxide, and the optimal generation rate and the selectivity of the propylene epoxide are 68.3 mu mol.g<-1>h<-1> and 52.3 percent respectively. The preparation method and the application method provided by the invention have the advantages of being simple in process condition, low in cost, good in repeatability and friendly in environment in the reaction process and can convert the propylene into an industrial product with higher value added.

Owner:SOUTHEAST UNIV

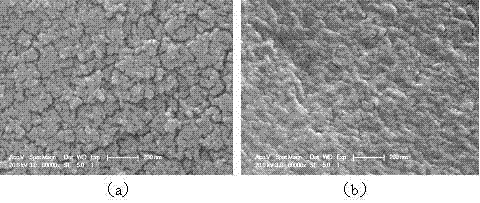

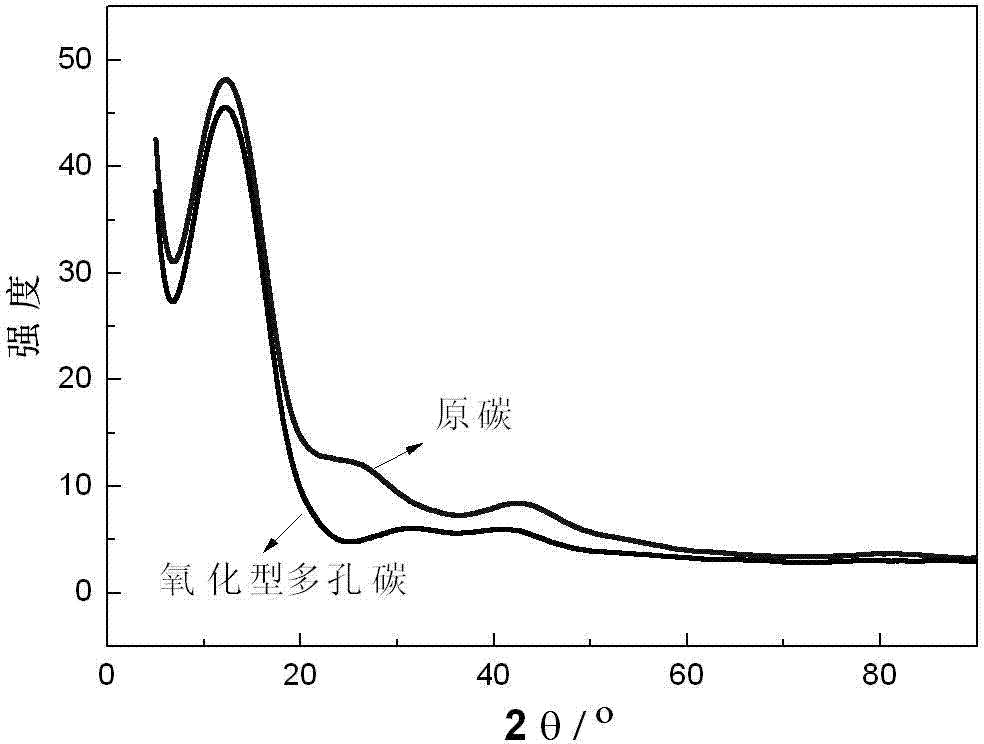

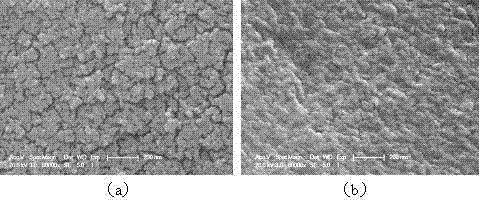

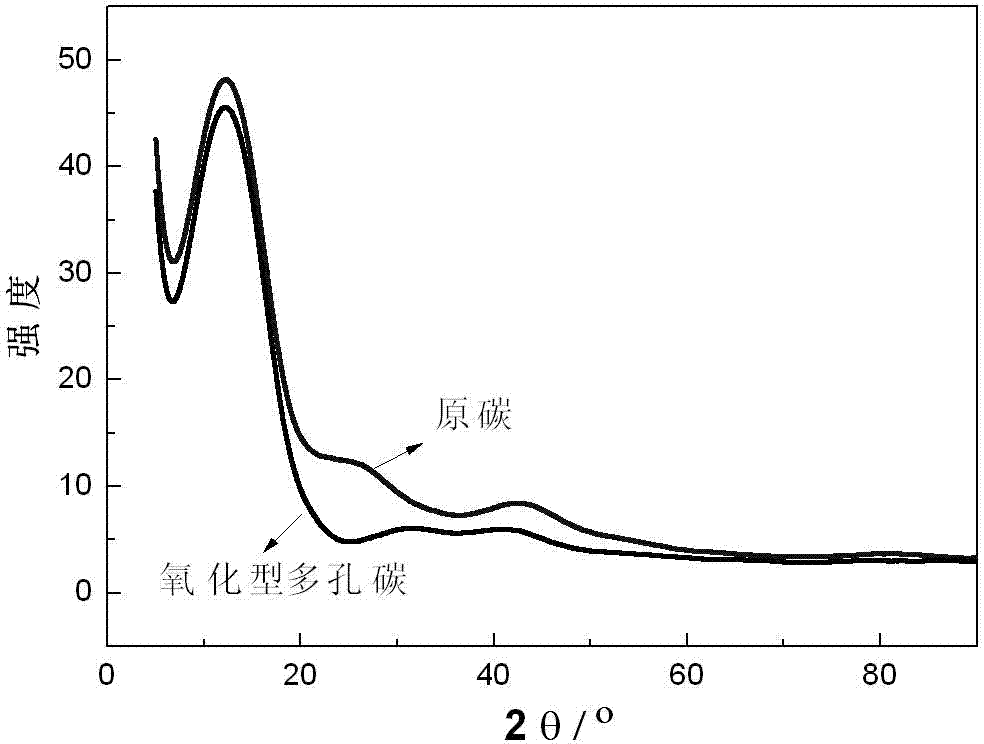

Treatment method of porous carbon carrier for noble metal catalysts

ActiveCN103691490AImprove surface propertiesControl specific surface areaCatalyst carriersNoble metalOxidizing agent

The invention belongs to the technical field of material preparations, and particularly relates to a treatment method of a porous carbon carrier for noble metal catalysts. The method treats the porous carbon carrier by using an oxidation reduction process, and comprises the following steps: firstly, treating the porous carbon carrier by using strong acid, then, adding a strong oxidant for oxidizing the treated porous carbon carrier to obtain oxidized form porous carbon, and at last, reducing the oxidized form porous carbon by using a reducing agent to obtain surface treatment porous carbon. By adopting the method, the specific surface area, pore passage structure and pore diameter of the carbon carrier can be improved and controlled, and meanwhile the hydrophilcity of the carbon carrier and the binding ability of the carbon carrier for the noble metal catalyst can be enhanced. By using the porous carbon loaded noble metal treated by the method, a carbon loaded noble metal catalyst with excellent comprehensive performance can be obtained. The processing method is simple, and low in cost, and can be used for scale production, and the yield is high.

Owner:JIANGXI HANS PRECIOUS METALS CO LTD

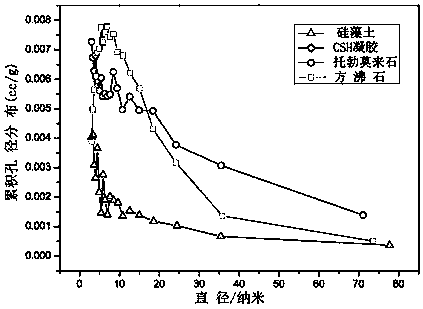

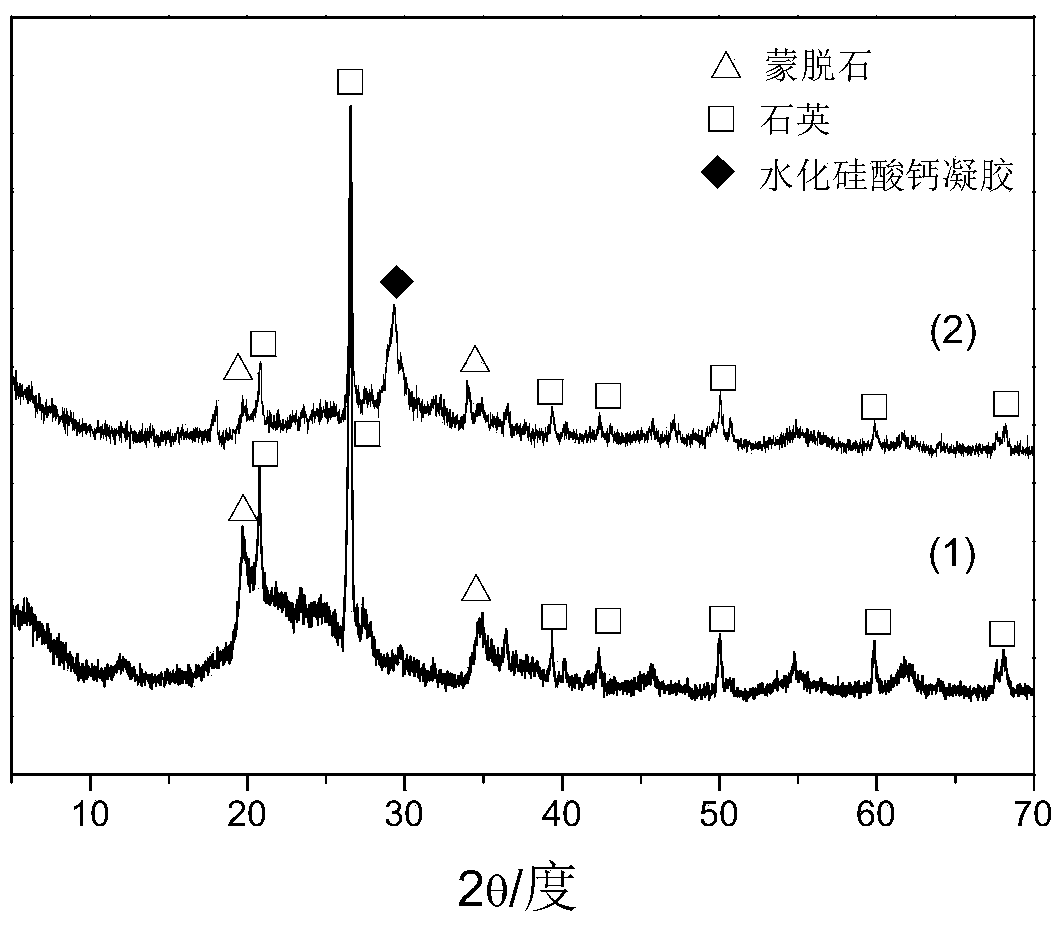

Method for treating methylene blue dye wastewater

ActiveCN103693758BRetain microporous structureReduce porosityOther chemical processesEnergy based wastewater treatmentSorbentBottle

The invention relates to a method for treating methylene blue dye wastewater. Firstly, diatomite is evenly mixed with calcium raw materials, alkali activator and water, and is put in a high-pressure hydrothermal reaction kettle after the compression molding to react for 1-48 hours at the temperature of 100-200 DEG C to obtain a diatomite-based porous adsorbent containing C-S-H, tobermorite and analcite; then, the diatomite-based porous adsorbent is put in a conical bottle accommodated with a liquid culture medium; 5-20% of yeast powder by mass is added to regulate the pH to be 5-8 and to cultivate for 2-48 h under the constant-temperature condition of 15-35 DEG C on a reciprocal shaking table with the speed of 60-120 rpm so as to obtain a yeast-loaded diatomite-based porous adsorbent; finally, 1-10 g of the yeast-loaded porous adsorbent is added in the methylene blue dye wastewater with per liter concentration of 100-1000 mg / L to treat for 1-48 h at the temperature of 25-45 DEG C on the reciprocal shaking table with the pH of 4 to 10 and the speed of 60-120 rpm; the concentration of the treated methylene blue wastewater is measured through a spectrophotometer method; the result shows that the removal rate of the methylene blue dye exceeds 90%. The method has the advantages of simple process, low cost and no secondary pollution, and is suitable for the industrial treatment of the methylene blue dye wastewater.

Owner:TONGJI UNIV

Calcium carbonate preparation method for accelerating carbonatation reaction

ActiveCN108046303AIncrease concentrationImprove solubilityCalcium/strontium/barium carbonatesMaterial nanotechnologyPrecipitated calcium carbonateCarbonatation

The invention discloses a calcium carbonate preparation method for accelerating a carbonatation reaction and belongs to the technical field of calcium carbonate powder preparation. The calcium carbonate preparation method for accelerating the carbonatation reaction comprises the steps that the inner wall of a carbonatation reaction kettle is coated with a carbon dioxide gas adsorption material, and after the coating material fixed on the inner wall of the reaction kettle, by using the reaction kettle which is improved through coating, the carbonatation reaction is conducted to prepare precipitated calcium carbonate. According to the calcium carbonate preparation method, the problems are solved that in the prior art, prepared calcium carbonate is long in reaction time and uneven and unstable in product quality.

Owner:GUANGXI UNIV +1

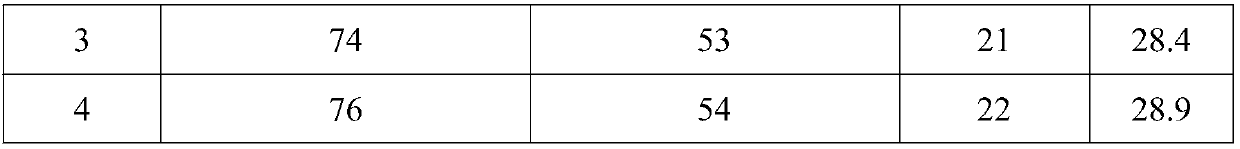

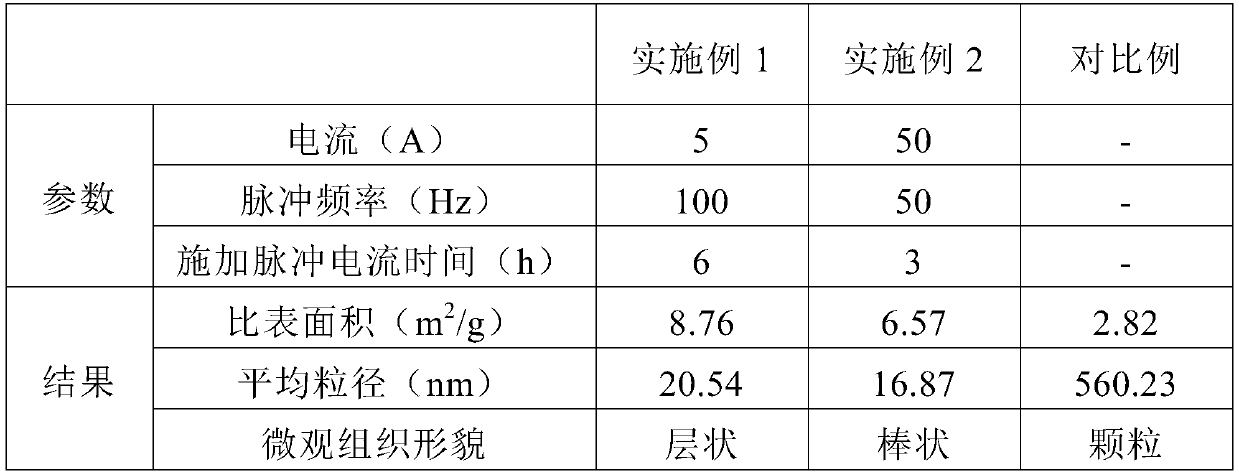

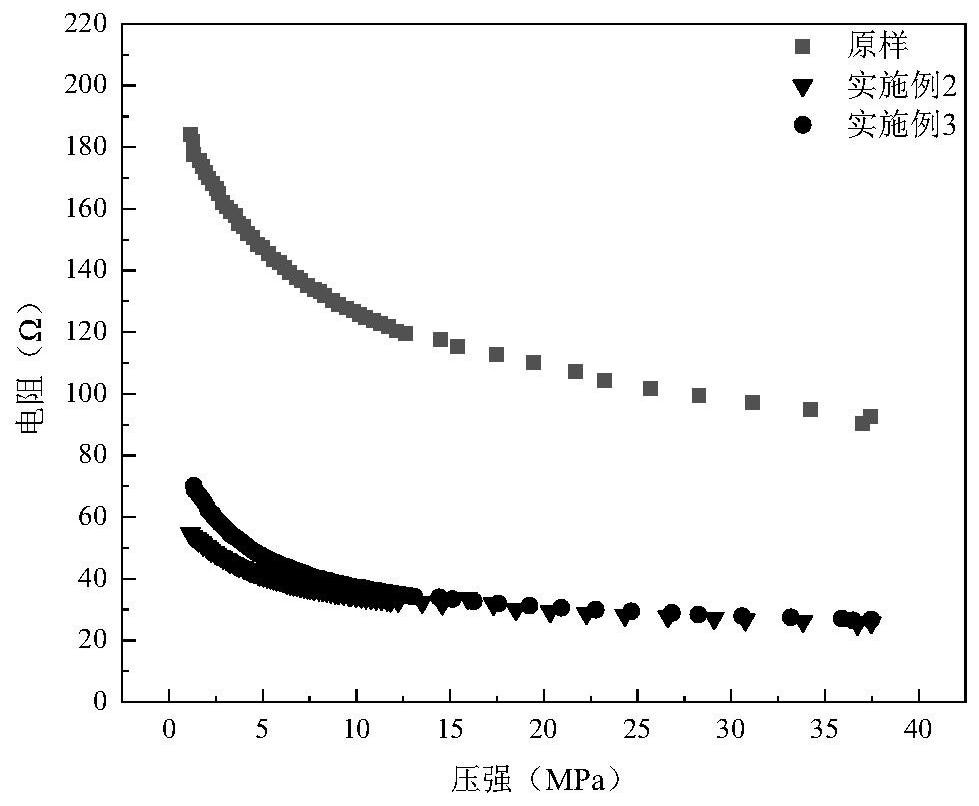

Preparation method of magnesium hydroxide powder

InactiveCN109761252ASimple stepsLow costNanotechnologyMagnesium hydroxidePulse frequencyMicrostructure

The invention provides a preparation method of magnesium hydroxide powder. The method comprises the following step: pulse current is applied in a reaction system when light calcined magnesia is utilized to prepare the magnesium hydroxide powder via hydration reaction. The magnitude of the pulse current applied in the reaction system is 5-1,000 A, and the used pulse frequency is 50-2,000 Hz. By adjusting the magnitude of the pulse current and the pulse frequency, the specific surface area, average particle size and microstructure and morphology of the magnesium hydroxide are controlled by the invention. Compared with the prior art, the preparation method provided by the invention has the following advantages: the process is simple, the cost is low, and the specific surface area, average particle size and microstructure and morphology of the magnesium hydroxide are easy to control.

Owner:ZHONGMIN CHIYUAN IND

Aerosil heat insulation material for building walls

The invention discloses an aerosil heat insulation material for building walls. The aerosil heat insulation material mainly comprises, by mass, 40-70 parts of silica sol, 12-25 parts of polyethylene glycol, 5.5-11.5 parts of glass fibers and 0.25-0.75 part of a cross-linking agent. The toughness of the aerosil is modified with the polyethylene glycol, and the mechanical properties of the aerosil are modified with the glass fibers, so the aerosil material has good stability and good heat resistance when used as a heat insulation material, and is an environmentally-friendly material.

Owner:成都圻坊生物科技有限公司

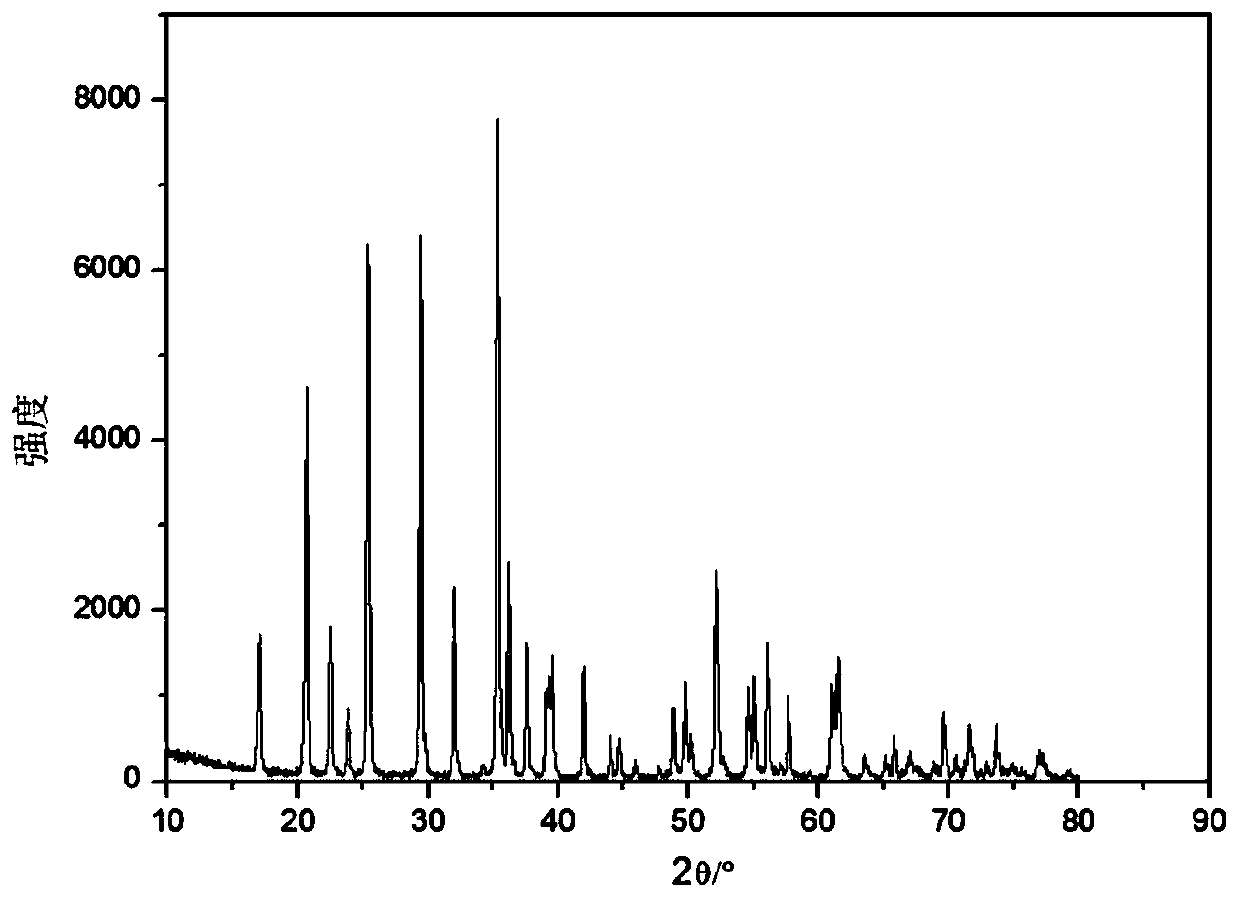

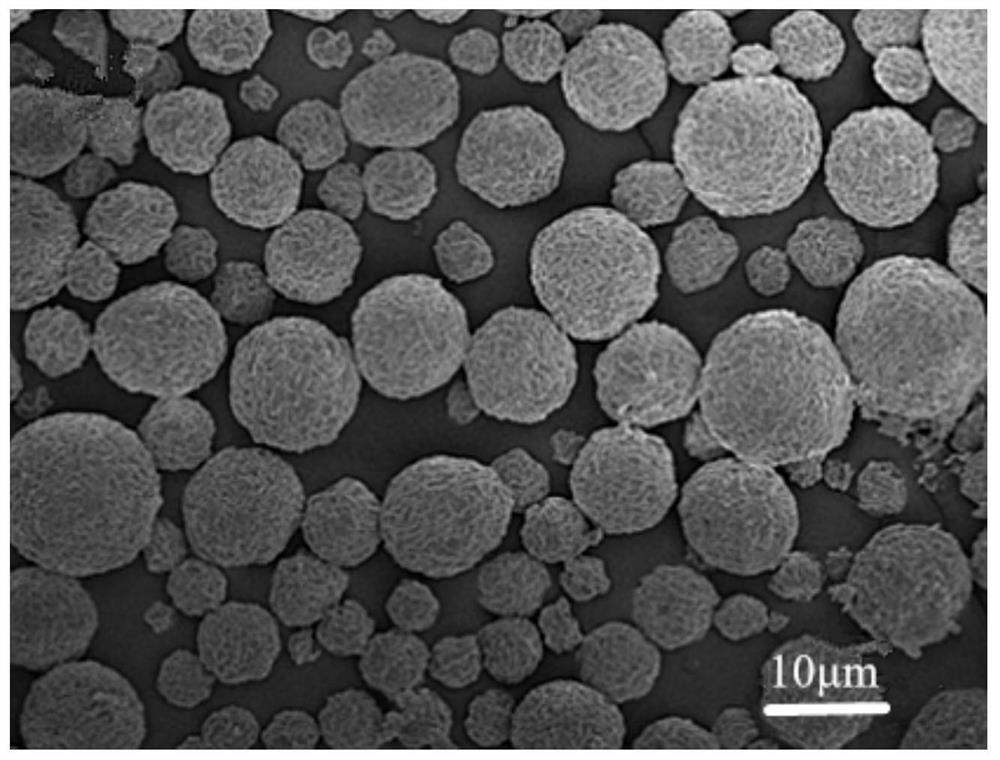

Graphene-coated lithium iron phosphate composite material and preparation method thereof

PendingCN112694078AControl specific surface areaLarge specific surface areaGrapheneSecondary cellsLithium iron phosphateSpray dried

The invention discloses a graphene-coated lithium iron phosphate composite material and a preparation method thereof, and belongs to the technical field of lithium ion batteries. The preparation method comprises the following steps: coating graphene oxide and lithium iron phosphate by adopting spray drying or evaporation drying to prepare a graphene-coated lithium iron phosphate solid, and carrying out heat treatment on the obtained graphene-coated lithium iron phosphate solid to prepare a graphene-coated lithium iron phosphate composite material, wherein the ratio of the sheet diameter of the graphene oxide to the D50 of the lithium iron phosphate is 0.05-40. According to the preparation method, the specific surface area of the obtained graphene-coated lithium iron phosphate composite material is effectively controlled by controlling the matching of the sheet diameter of graphene oxide and the particle size of lithium iron phosphate, and the processability of the coated material is greatly improved. Meanwhile, the resistivity of the prepared graphene-coated lithium iron phosphate composite material is reduced, and the charge-discharge performance of the material under high multiplying power can be improved.

Owner:SHAANXI COAL & CHEM TECH INST

A kind of preparation method of copper-iron-carbon aerogel electrode

ActiveCN106467323BWide variety of sourcesReduce processing costsWater/sewage treatment using germicide/oligodynamic-processHigh activityTreatment costs

The present invention relates to a copper-iron-carbon aerogel electrode preparation method. According to the method, resorcinol, formaldehyde, water, sodium carbonate, iron acetylacetonate and copper acetate monohydrate are uniformly mixed in a reaction container according to a certain ratio, a polymerization reaction is performed for a certain time at a certain temperature to prepare a wet gel, the wet gel is dried, programming heating and cooling is performed to prepare the copper-iron-carbon aerogel electrode, and the prepared copper-iron-carbon aerogel electrode is activated sequentially through CO2 and N2 so as to be used as the cathode in the degradation pool to degrade organic pollutants such as dimethyl phthalate and the like. Compared to the method in the prior art, the method of the present invention has advantages of simple preparation process, high activity, low treatment cost for degradation of organic pollutants such as DMP and the like, simple treatment process, flexible degradation, and the like.

Owner:TONGJI UNIV

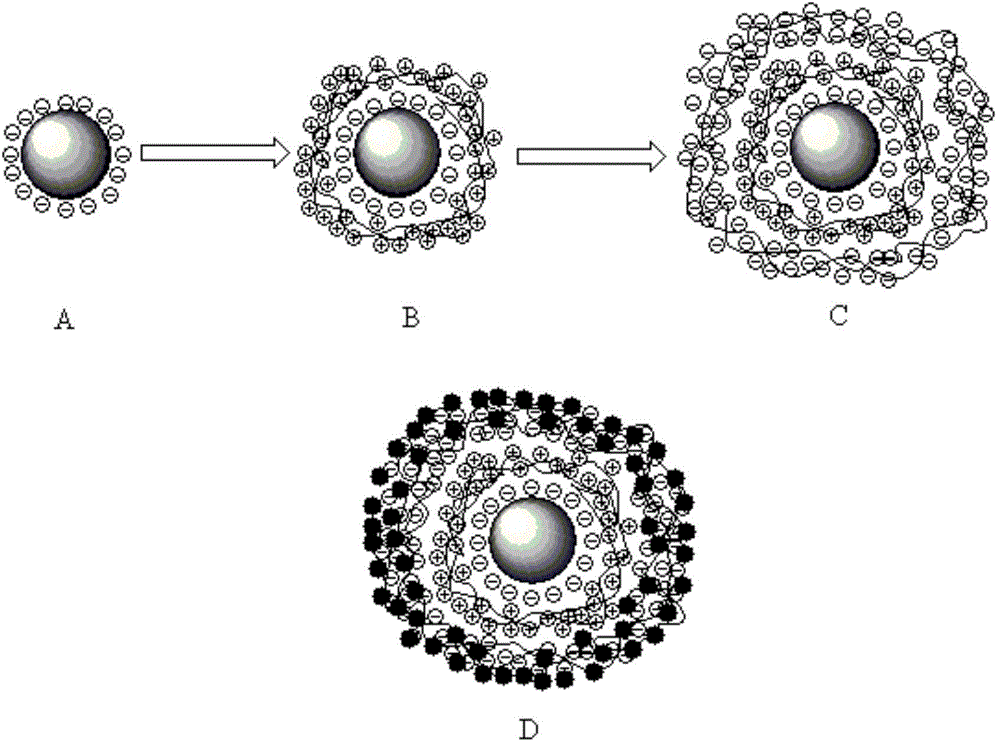

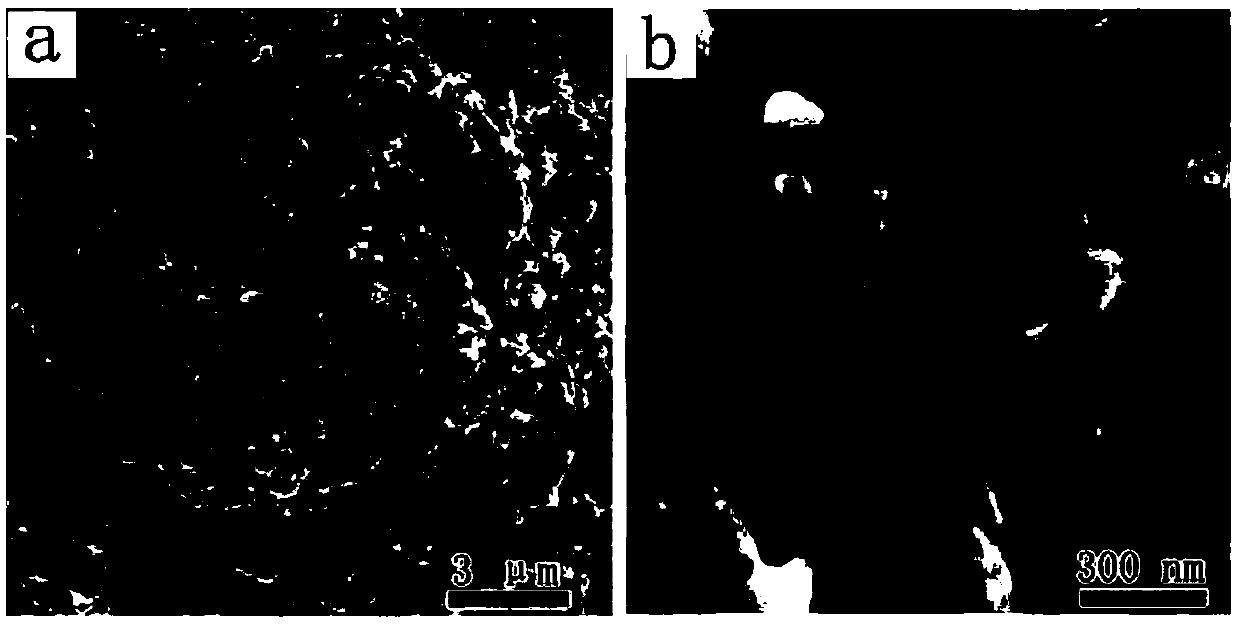

Method for loading nanoscale zero-valent iron on surface of quartz sand

InactiveCN105561946ADoes not change hydraulic characteristicsLow costOther chemical processesWater/sewage treatment by sorptionNanometreQuartz

The invention discloses a method for loading nanoscale zero-valent iron on the surface of quartz sand. The method comprises the steps of carrier pretreatment, electrolyte membrane assembling, ferrous ion uploading and reducing. The carrier pretreatment process particularly comprises the following steps that the quartz sand is weighed and immersed into a 15-30 g / L sodium persulfate solution with the pH ranging from 2 to 3, ultrasonic treatment is conducted at 60-70 DEG C, the treated quartz sand is cleaned with deionized water and then immersed into a 15-30 g / L sodium persulfate solution with the pH ranging from 12 to 13, ultrasonic treatment is conducted at 60-70 DEG C, and the treated quartz sand is cleaned with deionized water. According to the method for loading the nanoscale zero-valent iron on the surface of the quartz sand, the loading capacity and the particle size of the nanoscale zero-valent iron can be controlled, the reaction activity of the zero-valent iron can be effectively enhanced, and the method is suitable for restoration of groundwater.

Owner:WUXI HUANCHUANG ENVIRONMENT TECH DEV

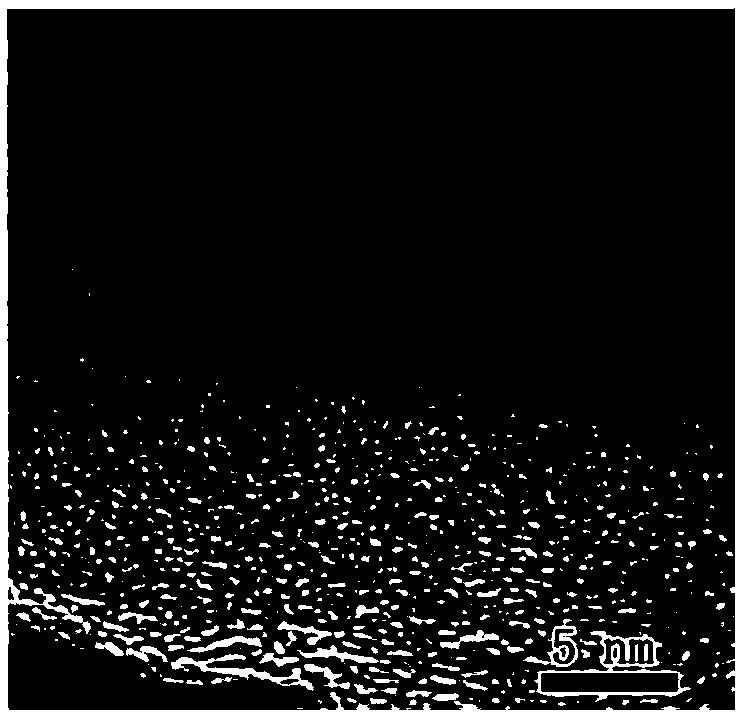

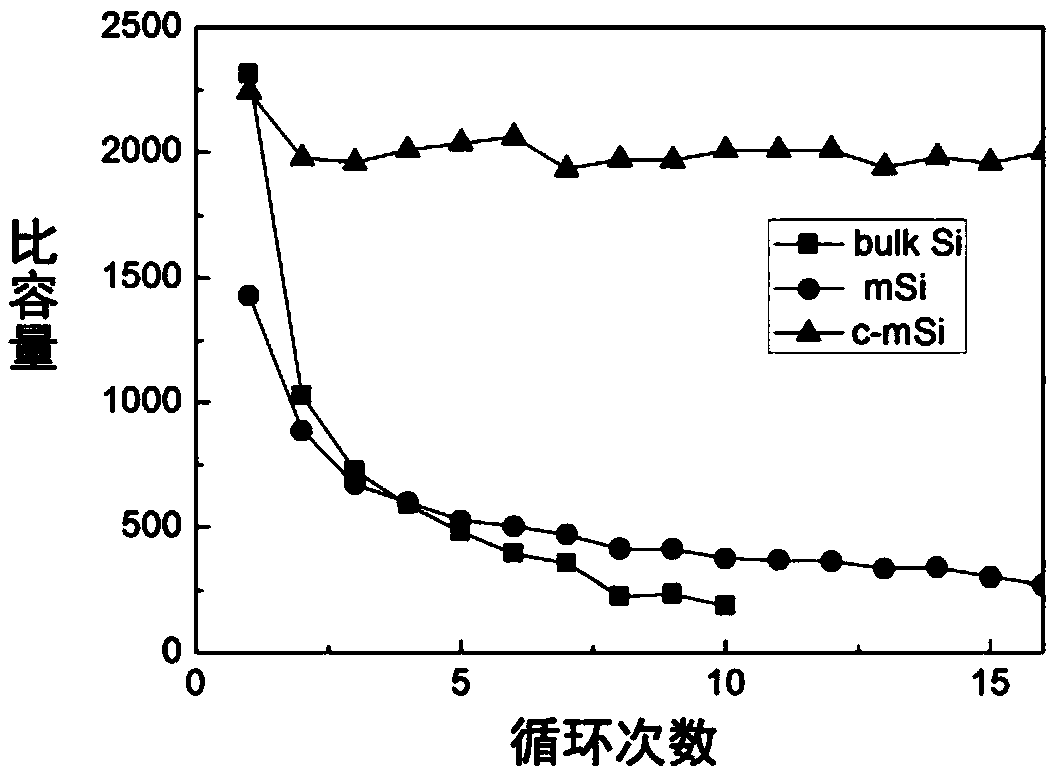

A kind of preparation method of porous silicon/carbon composite material

ActiveCN103779544BEasy to manufactureEase of industrial productionMaterial nanotechnologyCell electrodesCarbon compositesReduction treatment

The invention discloses a preparation method of a porous silicon / carbon composite material. The preparation method comprises the following steps: mixing decomposable silicide and a carbon source by a ball mill, carrying out heat treatment for 4-6 hours at 300-400 DEG C first, and then carrying out heat treatment for 12-20 hours at 600-800 DEG C, wherein the heat treatment process is carried out in a mixture of a protective gas and air and the volume ratio f the protective gas to the air is (10-50): 1; and treating a product obtained after heat treatment for 1-8 hours in an acid mixture of hydrochloric acid and hydrofluoric acid, and then centrifuging and drying to obtain the porous silicon / carbon composite material. The preparation method disclosed by the invention has the advantages that the preparation process is simple and convenient, a template or reduction treatment by metals is not required, and the used raw materials are industrial finished-products, thus being convenient for industrial production; the porous silicon / carbon composite material prepared by using the preparation method is adjustable in pore and size, and has relatively high coulombic efficiency and cycle stability when being used as a cathode material of a lithium ion battery.

Owner:ZHEJIANG UNIV

Preparation method of immobilized catalytic particle metal felt for producing biodiesel

ActiveCN108212179AImprove conversion rateSimple processPhysical/chemical process catalystsFatty acid esterificationBiodieselEthanol

The invention discloses a preparation method of an immobilized catalytic particle metal felt for producing biodiesel, aiming at solving the problems of an existing catalyst that the stability is poor,the service life is short and the catalytic efficiency is low. The preparation method comprises the following steps: carrying out ultrasonic washing on the metal felt with absolute ethyl alcohol andwater, and drying; preparing ZrOCl2.8H2O and nitrate into a mixed water solution; stirring and adding ammonia water until the pH (Potential of Hydrogen) is 9 to 10, so as to obtain flocculent sediment; standing at room temperature; then filtering and washing until no Cl<-> exists so as to obtain a filter cake; drying and grinding to obtain a powdered material; adding the powdered material into anH2SO4 solution to form a mixture; adding the dried metal felt into the mixture; after immersing, drying; roasting under an inert atmosphere at 400 to 600 DEG C for 3 to 7h to obtain the immobilized catalytic particle metal felt. The immobilized catalytic particle metal felt prepared by the preparation method has the advantages of high catalytic efficiency and mechanical strength, good stability and long service life; the preparation method has a simple technology and industrialized production is easy to realize.

Owner:HENAN INST OF ENG

Preparation method for pyrolytic carbon negative electrode material of mixed precursor for low-temperature power battery

ActiveCN109796000ALow costEasy to operateCell electrodesSecondary cellsPower batteryPyrolytic carbon

The invention discloses a preparation method for a pyrolytic carbon negative electrode material of a mixed precursor for a low-temperature power battery. The preparation method comprises the followingsteps that resin is dissolved in a solvent to prepare a resin solution, an additive is added, after uniform stirring, a stirring product is obtained, and the stirring product is dried and pretreated;after a pretreatment product is pyrolyzed, a pyrolysis product is cooled, levigated and sieved, and the pyrolytic carbon negative electrode material of the mixed precursor for the low-temperature power battery is prepared. The preparation method is simple in operation, common macromolecule low-cost materials of resin and the like are adopted, the compaction density is increased to 1.5-2.0 g / cm<3>, the macromolecule low-cost material is beneficial for increasing the volume energy density, and the specific surface area of the prepared negative electrode material is controlled to be 1-10 m<2> / g,the first coulombic efficiency exceeds 79%, the interlayer spacing is greater than 0.37 nm, then safety performance is good, and the negative electrode material is suitable for whole battery industrialization; the compaction density is high.

Owner:LIAONING TECHNICAL UNIVERSITY

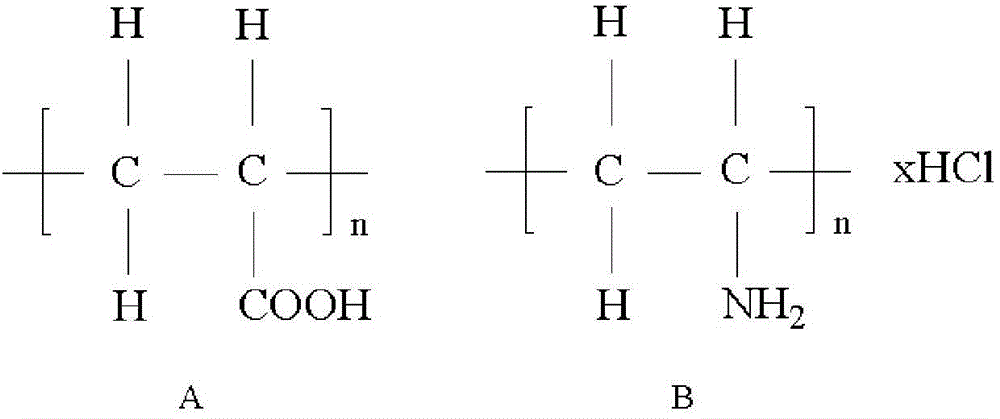

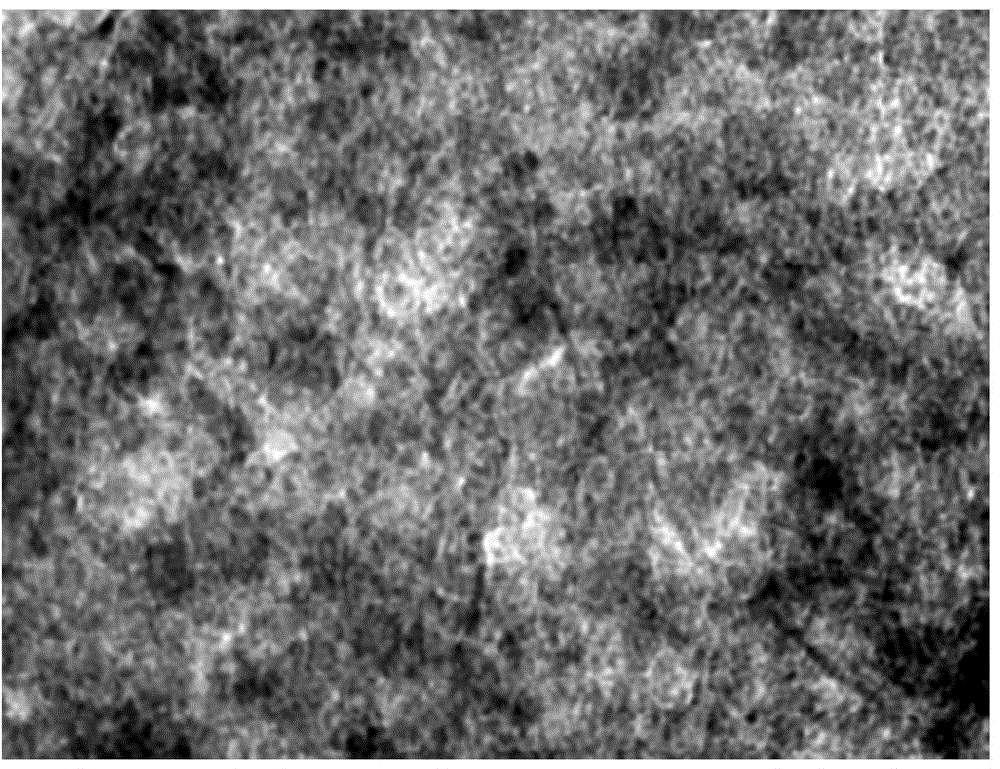

A preparation method of nitrogen-doped porous carbon/graphene two-dimensional composite electrode material

InactiveCN104934237BFacilitates in situ polymerizationHigh specific capacitanceHybrid capacitor electrodesHybrid/EDL manufactureElectrolytic agentPorous carbon

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Air-flow vortex balling machine for producing spherical graphite

The invention discloses an air-flow vortex balling machine for producing spherical graphite, which consists of a machine body, a balling drive device and an internal classification machine drive device, wherein an internal classification machine, a powder balling module and a cooling system are arranged in the machine body. In the invention, an internal balling module and a classification module are rationally arranged, and thus, the air-flow vortex balling machine for producing the spherical graphite is provided. The air-flow vortex balling machine can ensure that the graphite powder undergoes the physical processes of thinning, shearing, collision, friction, coiling, uniting and densification in an air-flow vortex balling room or can realize the combination of a physical balling processand a mechanical powder thinning process to prepare the spherical product. The indexes, such as sphericity, grain fineness distribution, tap density, apparent density, actual density and special surface area, of the spherical graphite powder can be controlled in the range of pre-determined values; the quality is stable; the yield can be improved by over three times; and over 50 percent of energy consumption can be reduced.

Owner:LUOYANG GUANQI INDAL & TRADE

A method for preparing magnesium silicate-based composite adsorption material by multiple co-precipitation method

ActiveCN110180495BImprove uniformityImproves Structural IntegrityOther chemical processesAlkali metal oxides/hydroxidesMagnesium saltMicrosphere

The invention discloses a method for preparing a magnesium silicate-based composite adsorption material by a multi-element co-precipitation method. The method uses a silicate solution and a magnesium salt solution as raw materials to prepare a magnesium silicate slurry; further adding the magnesium silicate slurry to the magnesium silicate slurry Adding carbonate solution to obtain magnesium silicate magnesium carbonate composite slurry; aging, filtering and washing to obtain magnesium silicate magnesium carbonate composite filter material; finally performing drying and molding treatment to obtain magnesium silicate-based composite adsorption material. The invention adds other active ingredients to expand the application range of the material; the method of pulping can improve the uniformity and structural integrity of the composite material. The magnesium silicate-based composite adsorption material microspheres and the hollow magnesium silicate-based composite adsorption material microspheres prepared by the spray drying method have significantly improved specific surface area and adsorption performance. The specific surface area of the material is further improved by adopting the rolling ball granulation method, and the obtained spherical particles of the composite adsorption material are convenient for industrial application due to their complete structure and morphology.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH +1

Process for treating porous carbon supports for noble metal catalysts

ActiveCN103691490BImprove surface propertiesControl specific surface areaCatalyst carriersPtru catalystPorous carbon

Owner:JIANGXI HANS PRECIOUS METALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com