Preparation method for nanometer yttrium oxide powder

A nanometer yttrium oxide and powder technology is applied in the field of preparation of rare earth ultrafine powder, which can solve the problems such as difficulty in controlling the growth rate of yttrium ions, and achieve the effects of being beneficial to precipitation and crystallization, improving purity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

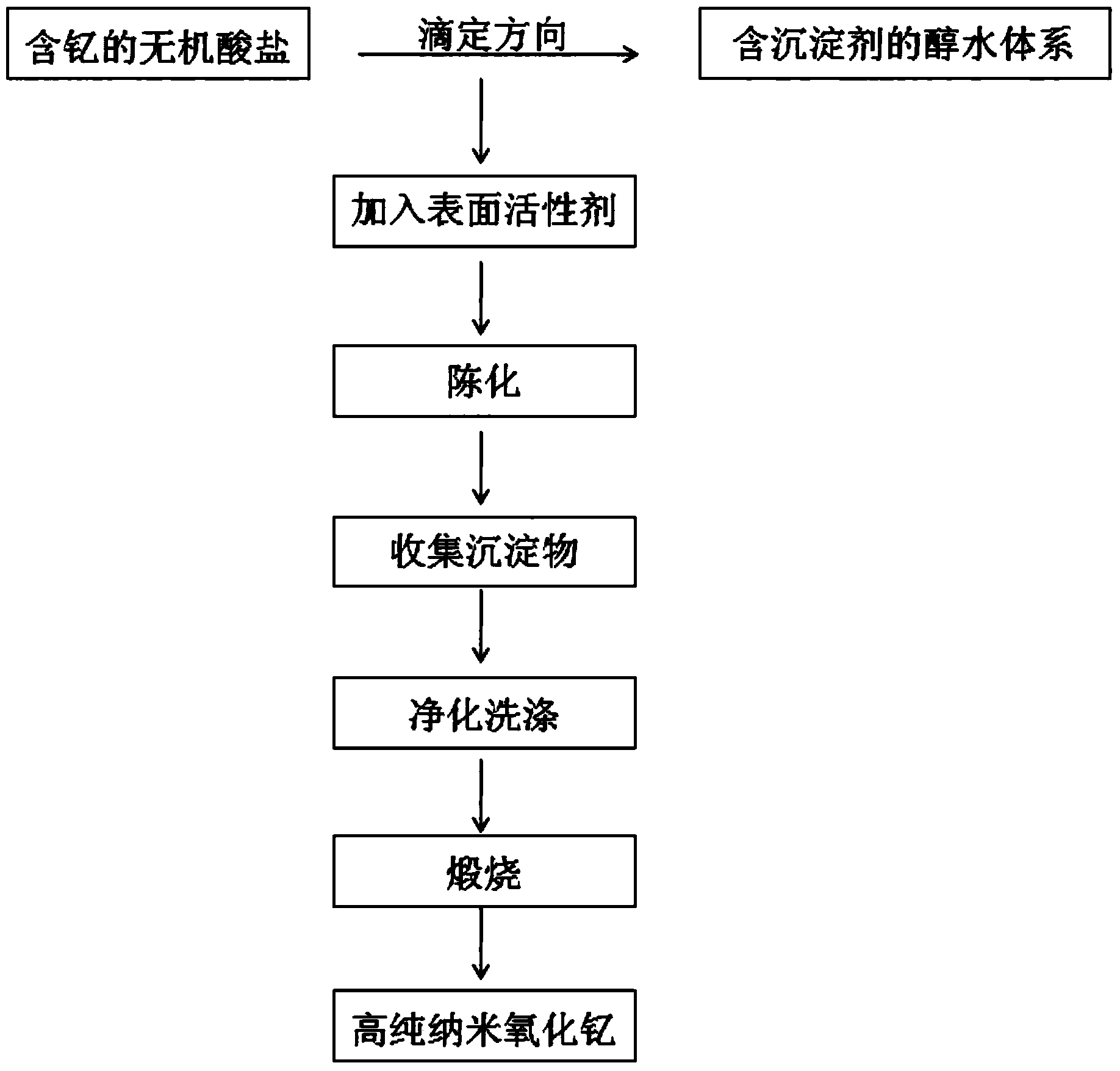

[0041] like figure 1 As shown, the embodiment of the present invention provides a kind of preparation method of nanometer yttrium oxide powder, and described method comprises:

[0042] Step 1: preparing an inorganic salt solution containing yttrium and an alcohol-water mixed solution containing a precipitating agent and an electrostatic stabilizer;

[0043] Step 2: Add the yttrium-containing inorganic acid salt solution dropwise to the alcohol-water mixed solution containing the precipitating agent and the electrostatic stabilizer, and adjust the pH value of the reaction system to not be lower than 7.5;

[0044] Step 3: After the titration reaction is completed, a surface modifier is added to the reaction system, and the reaction system is stirred, aged and separated, and the precipitate is taken;

[0045] Step 4: Purifying and washing the precipitate, vacuum drying and calcining to obtain nanometer yttrium oxide powder.

[0046] The preparation method of the nanometer yttri...

Embodiment 2

[0057] Dissolve high-purity yttrium oxide (purity greater than 99.999%) in concentrated nitric acid and transfer it to a 1L volumetric flask to make up a 0.4mol / L yttrium-containing nitrate solution; After ammonium and static stabilizer ammonium sulfate are dissolved in deionized water, the volume is adjusted to 1.5L with deionized water, and then 1L of absolute ethanol is added to the solution to prepare a precipitant and a static stabilizer with a concentration of 0.2mol / L. Alcohol-water mixed solution.

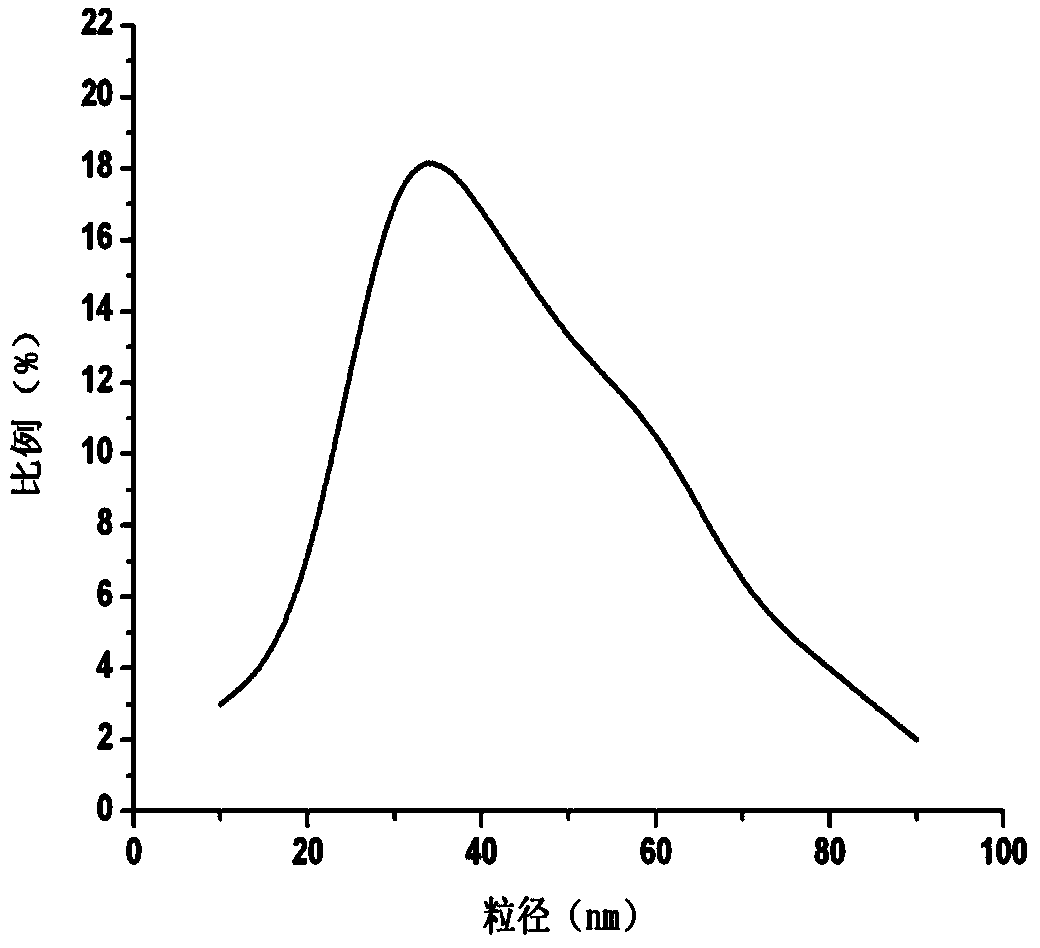

[0058] Add the above-prepared yttrium-containing nitrate solution dropwise to the above-prepared alcoholic aqueous solution containing a precipitating agent and an electrostatic stabilizer. During this process, control the dropping speed to 4ml / min, and use ammonia water to control the reaction system The pH value is not lower than 7.5; after the titration reaction is completed, add a surface modifier with a mass ratio of 0.3% to the yttrium-containing nitrate solution to t...

Embodiment 3

[0061] Dissolve high-purity yttrium oxide (purity greater than 99.999%) with concentrated sulfuric acid and transfer it to a 1L volumetric flask to make up a 0.1mol / L yttrium-containing nitrate solution; After the static stabilizer ammonium sulfate is dissolved in deionized water, the volume is adjusted to 1.0L with deionized water, and then 1L of absolute ethanol is added to the solution to prepare an alcohol with a concentration of 0.1mol / L for both the precipitant and the static stabilizer. water mixed solution.

[0062] Add the above-prepared yttrium-containing nitrate solution dropwise to the above-prepared alcoholic aqueous solution containing a precipitating agent and an electrostatic stabilizer. During this process, control the rate of dropping to 5ml / min, and use ammonia water to control the reaction system The pH value is not lower than 7.5; after the titration reaction is completed, add a surface modifier with a mass ratio of 0.4% to the yttrium-containing nitrate s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com