Lithium ferromanganese phosphate/carbon coated ternary material and preparation method thereof, lithium ion battery positive electrode and lithium ion battery

A lithium-ion battery and ternary material technology, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of difficult control of material phase purity, reduce side reactions in direct contact, low energy consumption, easy to use The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

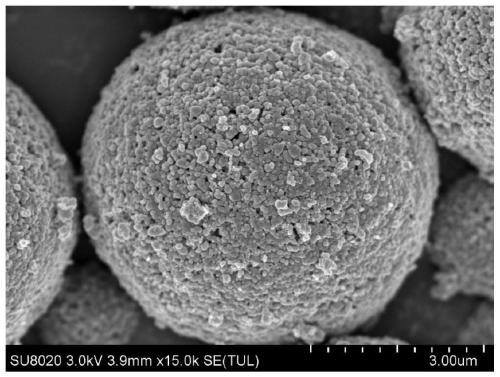

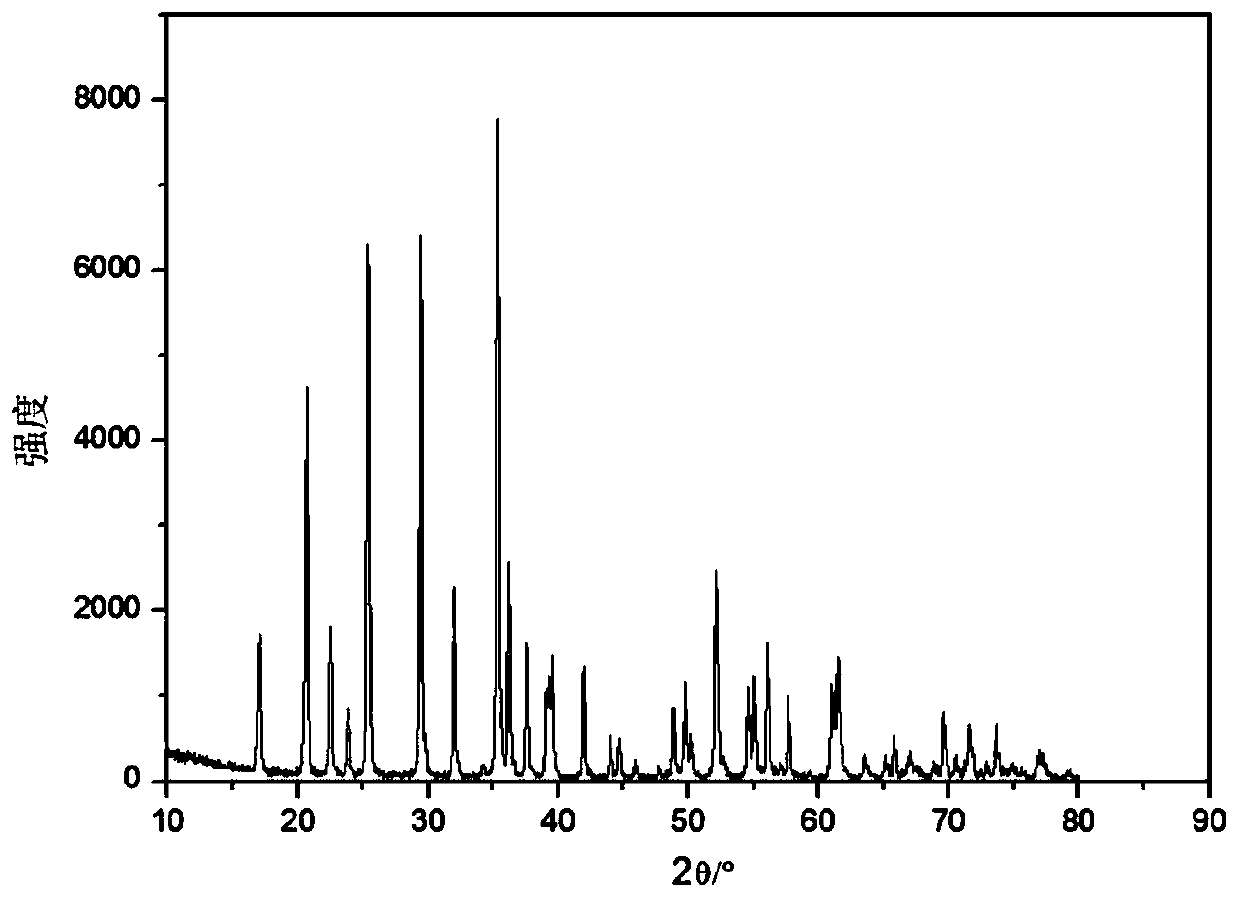

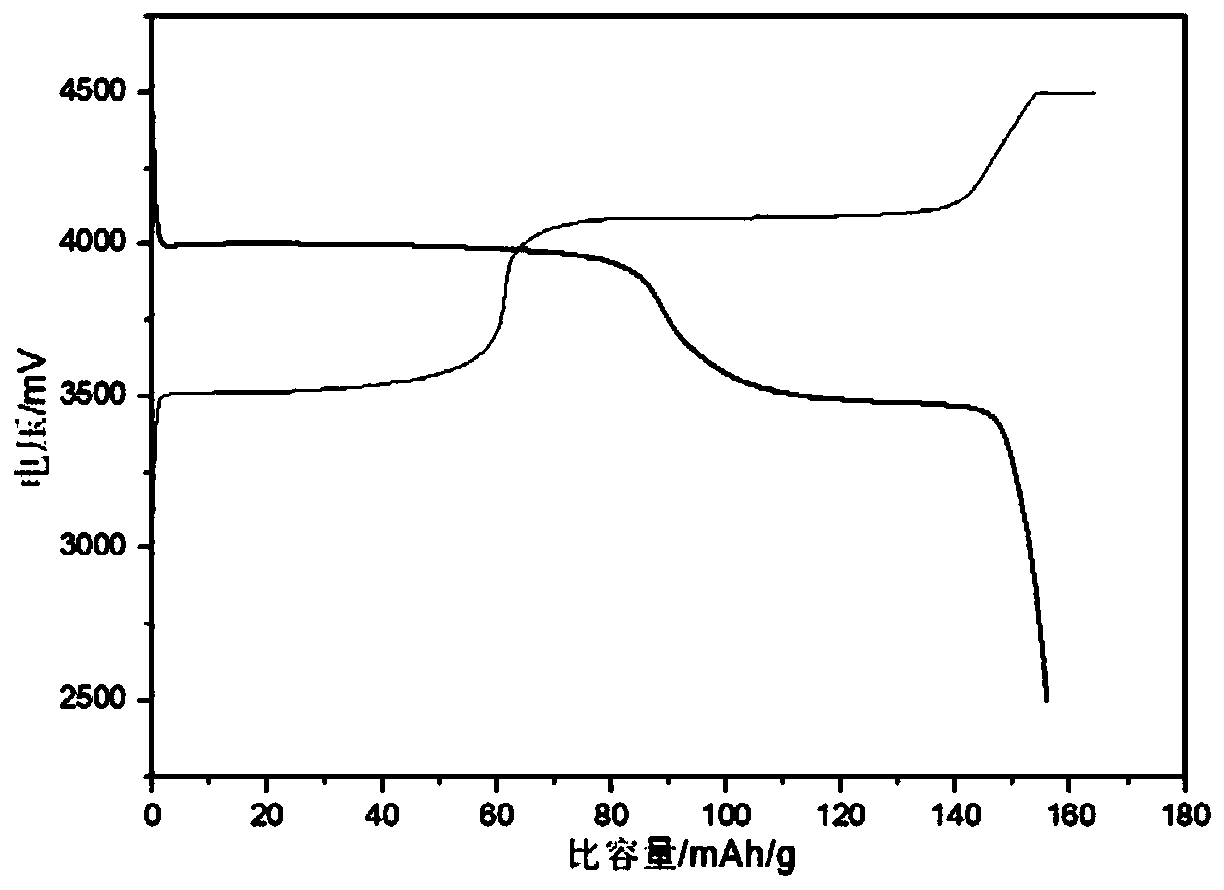

[0055] Preparation of LiMn by a two-step solid-phase method 0.6 Fe 0.4 PO 4 / C composite material, weigh 0.2molFe according to the stoichiometric ratio 2 o 3 , 0.2mol Mn 3 o 4 and 1mol LiH 2 PO 4 , and then weighed according to Fe 2 o 3 , Mn 3 o 4 , LiH 2 PO 4 The theoretical mass of 2wt% anhydrous glucose calculated by the number of moles, a certain amount of distilled water was added to the ball mill tank for wet ball milling for 2 hours, the slurry after ball milling was spray-dried to prepare precursor 1, and the precursor 1 was placed in Precursor 2 was obtained by oxidizing at 420°C for 4 hours in an air atmosphere, and then the precursor 2 was mixed with 9 wt% anhydrous glucose by weight of the precursor 2 for 2 hours by wet ball milling, and the precursor 3 was obtained after spray drying. Finally, under a nitrogen atmosphere, Calcined at 700°C for 4h, with a heating rate of 10°C / min, to obtain the final product LiMn 0.6 Fe 0.4 PO 4 / C Composite.

[00...

Embodiment 2

[0063] Preparation of LiMn by a two-step solid-phase method 0.6 Fe 0.4 PO 4 / C composite material, weigh 0.2molFe according to the stoichiometric ratio 2 o 3 , 0.2mol Mn 3 o4 and 1mol LiH 2 PO 4 , and then weighed according to Fe 2 o 3 , Mn 3 o 4 , LiH 2 PO 4 The theoretical mass of 2wt% anhydrous glucose calculated by the number of moles, a certain amount of distilled water was added to the ball mill tank for wet ball milling for 2 hours, the slurry after ball milling was spray-dried to prepare precursor 1, and the precursor 1 was placed in Precursor 2 was obtained by oxidation at 450°C for 4 hours in an air atmosphere, and then the precursor 2 and 10wt% anhydrous glucose by weight of the precursor 2 were mixed by wet ball milling for 2 hours, and the precursor 3 was obtained by spray drying. , calcined at 720°C for 4h, and the heating rate was 10°C / min to obtain the final product LiMn 0.6 Fe 0.4 PO 4 / C Composite. The performance of the composite material is ...

Embodiment 3

[0068] Preparation of LiMn by a two-step solid-phase method 0.7 Fe 0.3 PO 4 / C composite material, weigh 0.35molFe according to the stoichiometric ratio 2 o 3 , 0.1mol Mn 3 o 4 and 1mol LiH 2 PO 4 , and then weighed according to Fe 2 o 3 , Mn 3 o 4 , LiH 2 PO 4 Anhydrous glucose of 5wt% of the theoretical mass calculated by moles, a certain amount of distilled water was added to the ball mill tank for wet ball milling for 2 hours, and the slurry after ball milling was spray-dried to obtain precursor 1, and the precursor 1 was placed in Precursor 2 was obtained by oxidation at 500°C for 2 hours in an air atmosphere, and then the precursor 2 and 10wt% anhydrous glucose by weight of the precursor 2 were mixed by wet ball milling for 2 hours, and the precursor 3 was obtained by spray drying. Finally, under a nitrogen atmosphere, Calcined at 730°C for 4h, with a heating rate of 10°C / min, to obtain the final product LiMn 0.7 Fe 0.3 PO 4 / C Composite. The performance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com