Preparation method of immobilized catalytic particle metal felt for producing biodiesel

A technology of biodiesel and metal felt, applied in chemical instruments and methods, physical/chemical process catalysts, biofuels, etc., can solve the problems of reduced service life, achieve long service life, solve the effects of low operating temperature and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

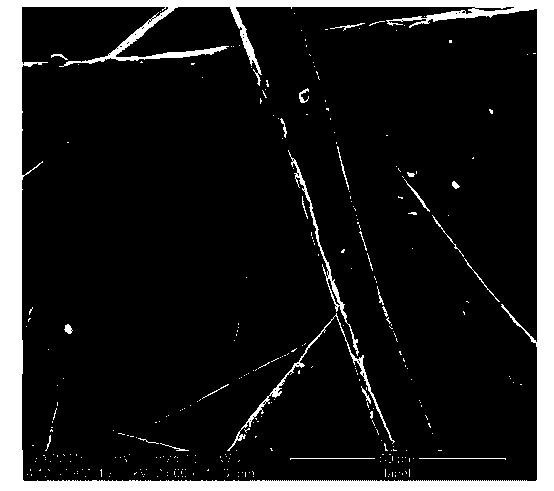

[0036] Embodiment 1: The preparation method of the solid-supported catalytic particle metal felt for producing biodiesel

[0037] 1) Set the porosity to 60% and the specific surface area to 1000m 2 / g of stainless steel metal felt was soaked in absolute ethanol, ultrasonically cleaned for 15 min, then ultrasonically cleaned with deionized water for 15 min, and dried for later use.

[0038] 2) ZrOCl 2 ·8H 2 O and Zn(NO 3 ) 2 ·6H 2 O was formulated into an aqueous solution according to a molar ratio of 1:1, and the pH of the aqueous solution was adjusted to 9-10 with concentrated ammonia water under magnetic stirring to obtain a mixture with flocculent precipitates, and the mixture was aged at room temperature for 24 hours. Suction filtration, washing to no Cl - , and finally carry out suction filtration to obtain a filter cake, put the filter cake in a drying oven and dry at 110 °C for 12 hours to obtain a powder, take it out and cool it to room temperature, grind the po...

Embodiment 2

[0040] Embodiment 2: The preparation method of the solid-supported catalytic particle metal felt for producing biodiesel

[0041] The difference of Example 1 is: the ZrOCl 2 ·8H 2 O and Zn(NO 3 ) 2 ·6H 2 The molar ratio of O is: 2:1, and finally the solid-loaded SO is obtained 4 2- / ZrO 2 -The metallic felt of ZnO catalytic particle; All the other are identical with embodiment 1.

Embodiment 3

[0042] Embodiment 3: The preparation method of the solid-supported catalytic particle metal felt for producing biodiesel

[0043] Different from Example 1: with Fe (NO 3 ) 3 9H 2 O replaces the Zn in the embodiment 1 (NO 3 ) 2 ·6H 2 O, and finally get the immobilized SO 4 2- / ZrO 2 -Fe 2 o 3 The metallic felt of catalytic particle; All the other are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com