Method for loading nanoscale zero-valent iron on surface of quartz sand

A nano-zero-valent iron, surface-loaded technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc., can solve problems such as unfavorable electrolyte adsorption, low charge density, weak free radicals, etc., and achieve low cost. , strong permeability, the effect of improving the charge density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Preparation of zero valent iron

[0036] 1) Prepare pH 2, 20g / L Na in advance 2 S 2 o 8 solution and pH 12, 20g / L Na 2 S 2 o 8 solution.

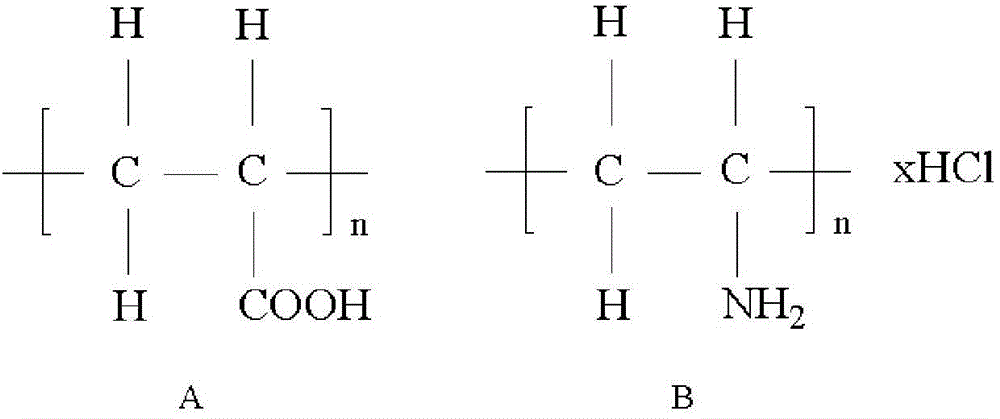

[0037] 2) Prepare PAA and PAH solutions with a concentration of 1g / L and 0.1mol / L FeSO 4 solution, and adjust the pH to 3.0 with 0.1 mol / L HCl and NaOH solution.

[0038]3) Preheat the ultrasonic machine to 70°C, weigh 200-mesh quartz sand and immerse it in pH 2, 20g / L Na 2 S 2 o 8 Solution, ultrasonic at 70°C for 10 minutes, pour out the waste liquid after taking it out, wash with water 3 times, 2 minutes each time.

[0039] 4) Immerse in pH12, 20g / L Na 2 S 2 o 8 Solution, ultrasonic at 70°C for 10 minutes, pour out the waste liquid after taking it out, wash with water 3 times, 2 minutes each time.

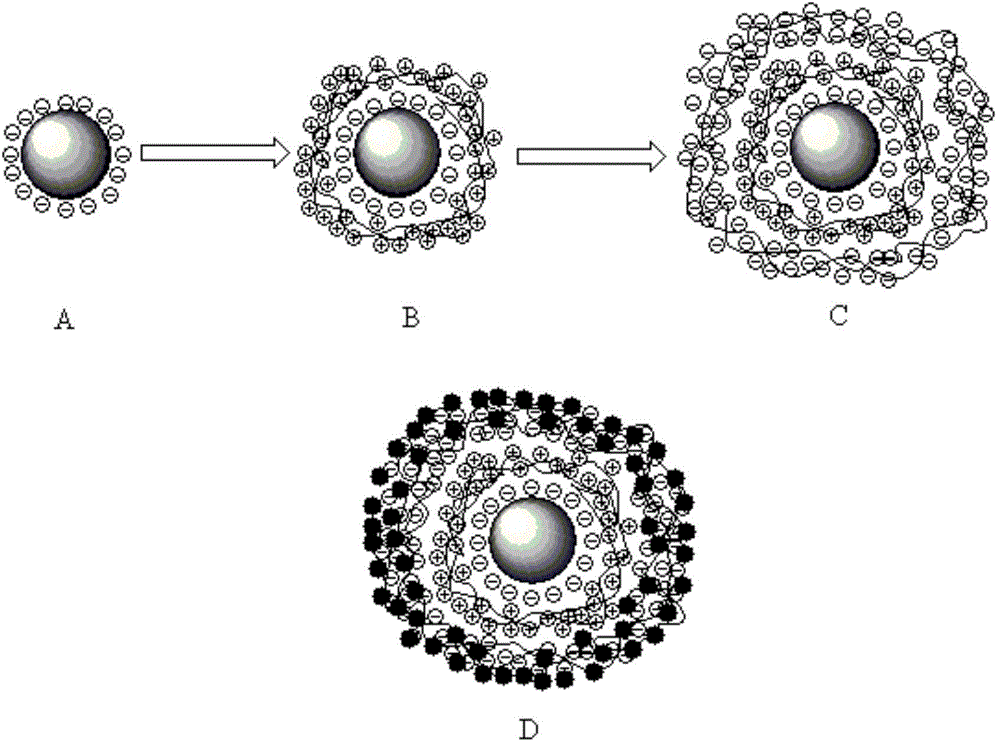

[0040] 5) Soak in 1g / LPAH for 5min, wash with water 3 times, 2min each time.

[0041] 6) Soak in 1g / LPAA for 5min, wash with water 3 times, 2min each time.

[0042] 7) Repeat steps 4 and 5 above for m times (m=3, 6, 9, 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com