Synthesizing nano crystal cobalt aluminium spinelle pigment by using solution combustion method

A technology of solution combustion and nanocrystals, applied in the direction of fibrous fillers, dyeing physical treatment, etc., can solve the problems of long time required for the synthesis process and complicated process, and achieve the effects of narrow particle size distribution, simple reaction process and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

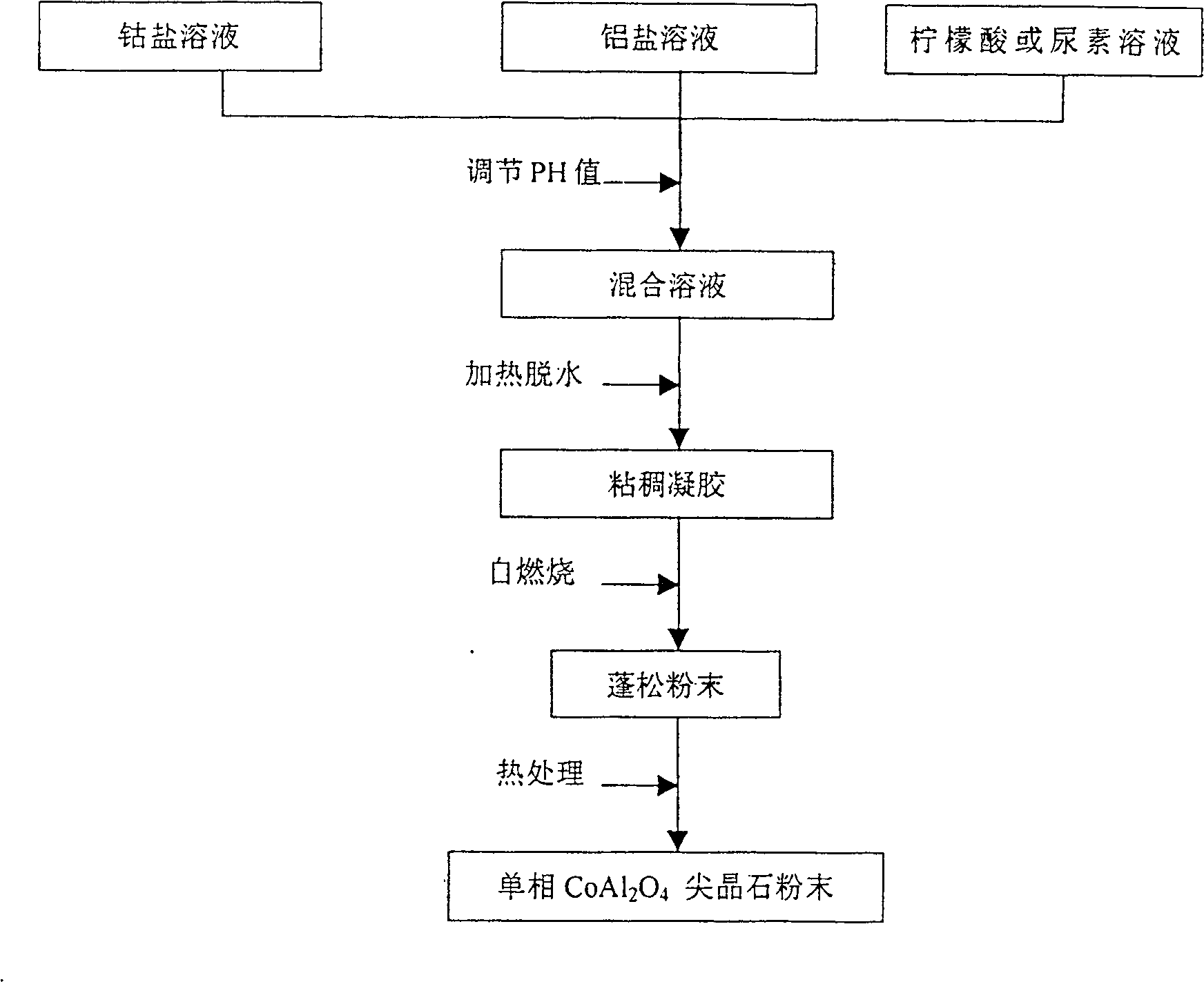

Method used

Image

Examples

Embodiment 1

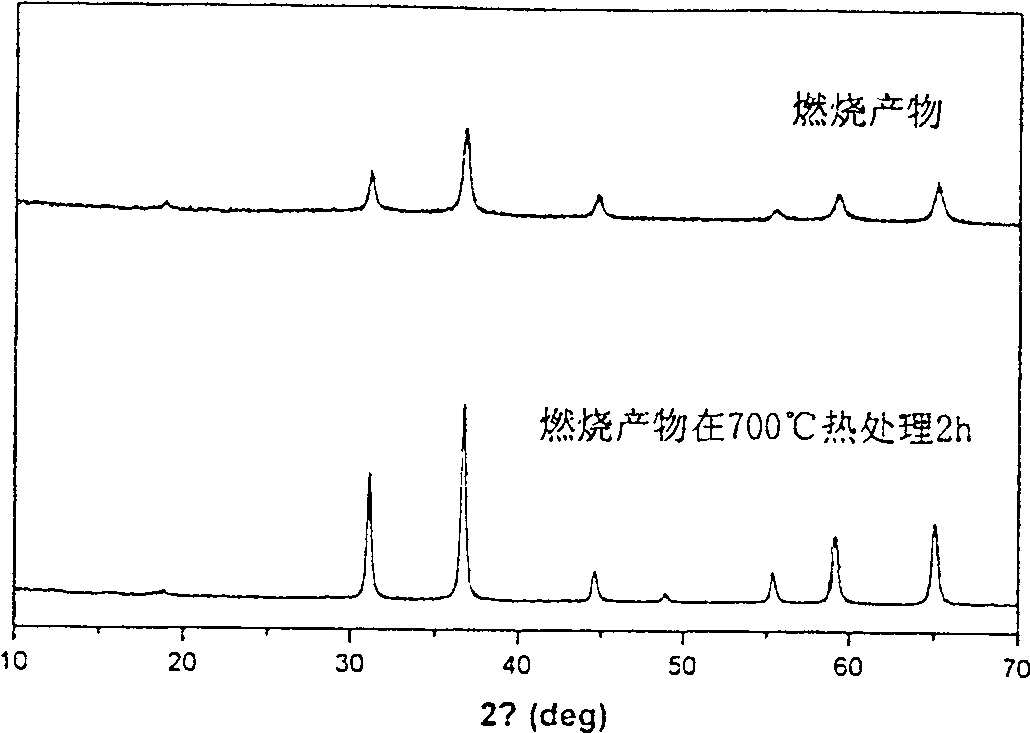

[0025] Use aluminum nitrate, cobalt acetate and citric acid as raw materials, according to Co 2+ :Al 3+ : citric acid molar ratio = 1:2:2 ingredients, the method is as follows: respectively dissolve aluminum nitrate, cobalt acetate and citric acid in deionized water to make a solution, stir continuously after mixing, adjust the pH to 7 with ammonia water, and stir fully Afterwards, heat in a microwave cavity. The microwave frequency is 2.45GHz, and the input power is 500W. As the water vapor evaporates, the solution concentrates, forming a gel. When reaching a certain temperature, the gel ignites and spontaneously burns for about 5 minutes, and a fluffy foamy powder is obtained. The above powder was heat-treated in air at 700°C for 2 hours to obtain the final product, whose XRD pattern is as follows: figure 2 , TEM photo as Figure 5 . CoAl 2 o 4 The average particle size of the powder (calculated by the Scherrer equation) is 19nm, and the specific surface area is 59m...

Embodiment 2

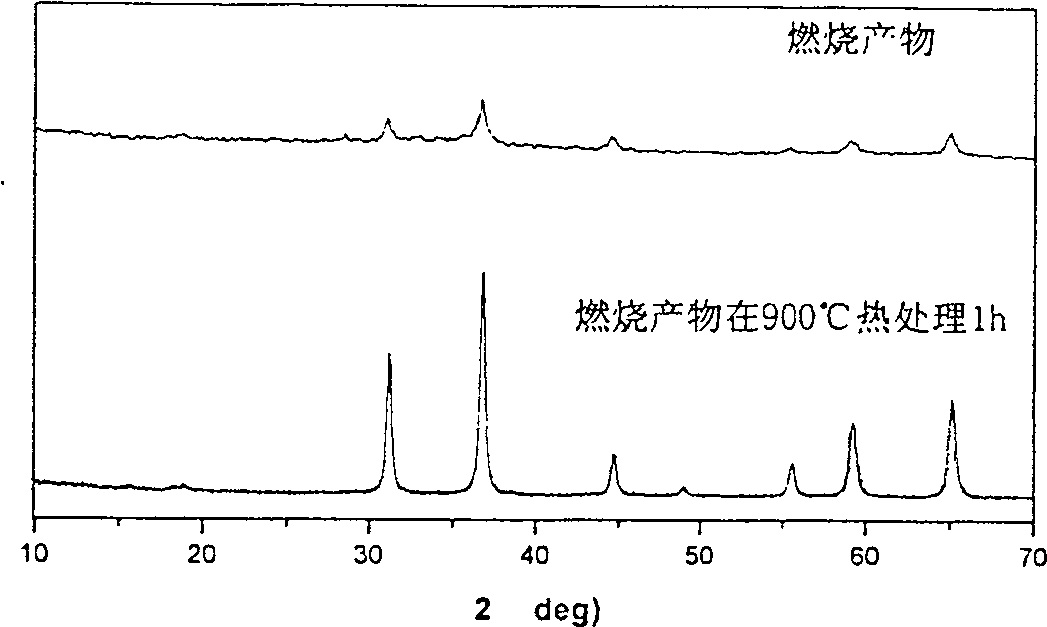

[0027] Use aluminum sulfate, cobalt nitrate and citric acid as raw materials, according to Co 2+ :Al 3+: citric acid molar ratio = 1:2:3 ingredients, the method is as follows: respectively dissolve aluminum sulfate, cobalt nitrate and citric acid in deionized water to make a solution, stir continuously after mixing, adjust the pH to 7 with ammonia water, and stir thoroughly Afterwards, heat on an electric stove. As the water evaporates, a gel is formed. Then put the gel in a muffle furnace. When the temperature reaches 300°C, the gel will ignite and spontaneously burn for about 15 minutes, and a fluffy foamy powder will be obtained. The above powder was heat-treated in air at 900°C for 1 hour to obtain the final product, whose XRD pattern is as follows: image 3 , TEM photo as Image 6 . Obtained CoAl 2 o 4 The average particle size of the powder (calculated by the Scherrer equation) is 31nm and the specific surface area is 43m 2 / g.

Embodiment 3

[0029] Use aluminum nitrate, cobalt nitrate, and urea as raw materials, according to Co 2+ :Al 3+ : urea molar ratio=1:2:10 ingredients, the method is as follows: respectively dissolve aluminum nitrate, cobalt nitrate, and urea in deionized water to make a solution, stir continuously after mixing, and heat in a microwave cavity. The microwave frequency is 2.45GHz, and the input power is 500W. As the water vapor evaporates, the solution concentrates, forming a gel. When reaching a certain temperature, the gel ignites and burns spontaneously for about 2 minutes, and a fluffy foamy powder is obtained. The above powder was heat treated in air at 500°C for 3 hours to obtain the final product, whose XRD pattern is as follows: Figure 4 , TEM photo as Figure 7 . Obtained CoAl 2 o 4 The average particle size of the powder (calculated by the Scherrer equation) is 42nm and the specific surface area is 37m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com