Graphene-coated lithium iron phosphate composite material and preparation method thereof

A technology of graphene-coated lithium iron phosphate and composite materials, which is applied in the field of graphene-coated lithium iron phosphate composite materials and its preparation, can solve the problems of shortened diffusion distance, high preparation cost, increased specific surface of nanoparticles, etc. Improve rate performance and its low temperature performance, excellent dispersion characteristics, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

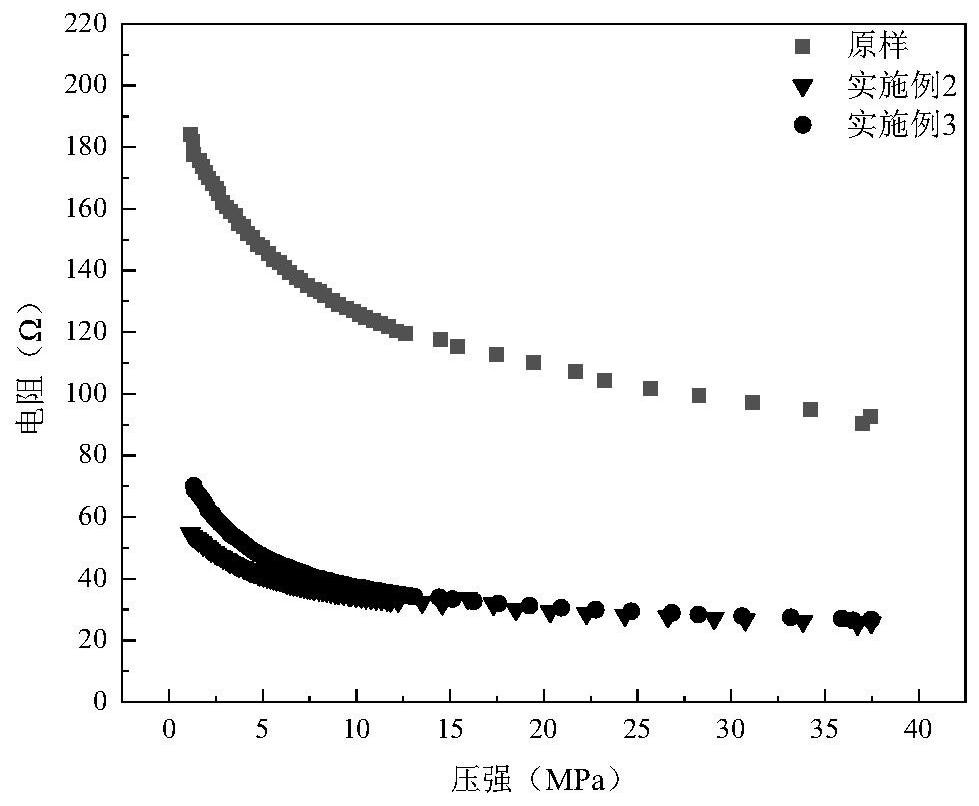

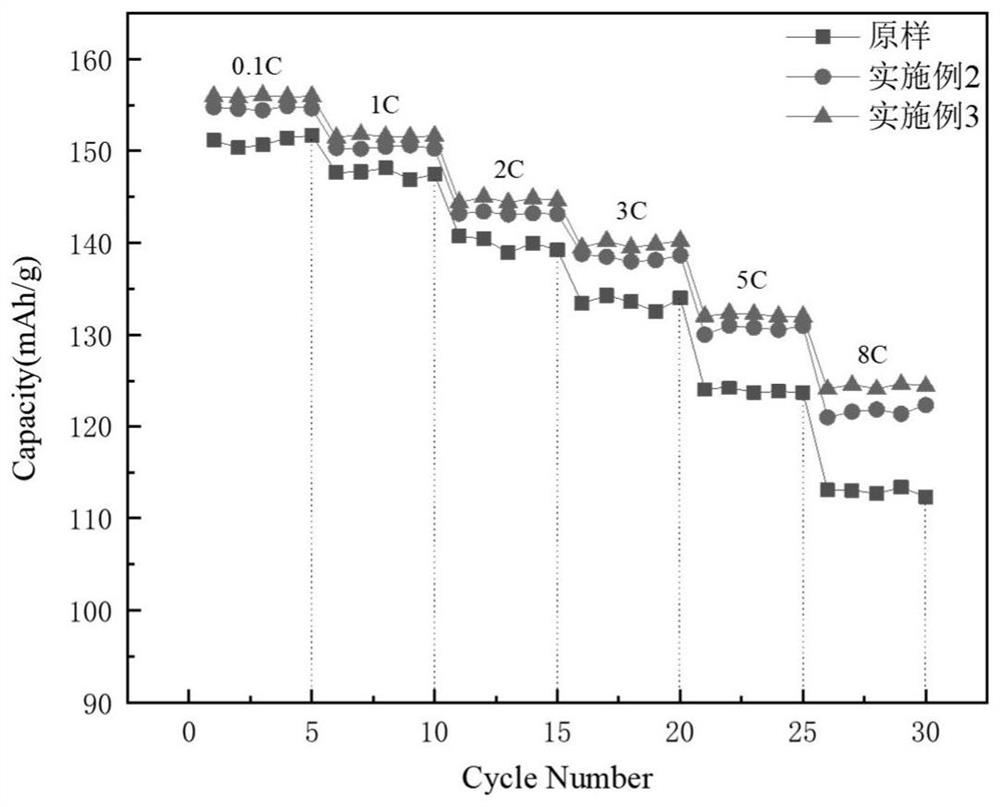

[0028] The invention discloses a preparation method of a highly conductive graphene-coated lithium iron phosphate composite material, comprising: ultrasonically dispersing graphene oxide in a solvent to obtain solution A, and ultrasonically dispersing lithium iron phosphate in the solvent to obtain solution B , the obtained solution A and solution B are mixed and uniformly dispersed by ultrasonic to obtain a mixed solution, and the obtained mixed solution is dried to obtain a graphene-coated lithium iron phosphate precursor, and the obtained graphene-coated lithium iron phosphate precursor is subjected to Heat treatment to prepare graphene-coated lithium iron phosphate composite material.

[0029] (1) The ratio of the diameter of the graphene oxide sheet of the raw material to the D50 of the raw material lithium iron phosphate is 0.05 to 40;

[0030] (2) in the obtained graphene-coated lithium iron phosphate solid according to the ratio control of (1), the coating amount of gr...

Embodiment 1

[0039] Graphene oxide is ultrasonically dispersed in water to obtain dispersion A, and lithium iron phosphate is ultrasonically dispersed in water to obtain dispersion B, and the obtained dispersion A and dispersion B are mixed and uniformly dispersed by ultrasonic to obtain a mixed dispersion. The obtained mixed dispersion liquid is dried to obtain a graphene-coated lithium iron phosphate precursor, and the obtained graphene-coated lithium iron phosphate precursor is subjected to heat treatment to obtain a graphene-coated lithium iron phosphate composite material.

[0040] Among them, the diameter of graphene oxide sheet is 1 μm, and the specific surface area is 70m 2 / g, lithium iron phosphate D50: 0.9μm, specific surface area: 18m 2 / g, the ratio of graphene oxide sheet diameter to lithium iron phosphate D50 is 0.55, the coating amount is controlled to 3.5%, coating is carried out by spray drying, the inlet temperature is 100°C, the outlet temperature is 80°C, the heat trea...

Embodiment 2

[0042] Adopt the preparation method process as described in embodiment 1, concrete parameter is as follows:

[0043] Choose graphene oxide sheet diameter 5μm, specific surface area: 30m2 / g, lithium iron phosphate D50: 0.9μm, specific surface area: 18m 2 / g, the ratio of graphene oxide sheet diameter to lithium iron phosphate D50 is 5.5, the coating amount is controlled at 1.5%, coating is carried out by spray drying, inlet temperature: 120°C, outlet temperature: 100°C, heat treatment temperature 400°C, The time is 5 hours. The particle size of the obtained graphene-coated lithium iron phosphate composite material after coating is about 3 μm, and the specific surface area: 12.5-13m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com