A method for preparing magnesium silicate-based composite adsorption material by multiple co-precipitation method

A composite adsorption material and a technology of co-precipitation method are applied in the field of preparing magnesium silicate-based composite adsorption materials by multivariate co-precipitation method. Large-scale application, high adsorption capacity, and the effect of improving specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

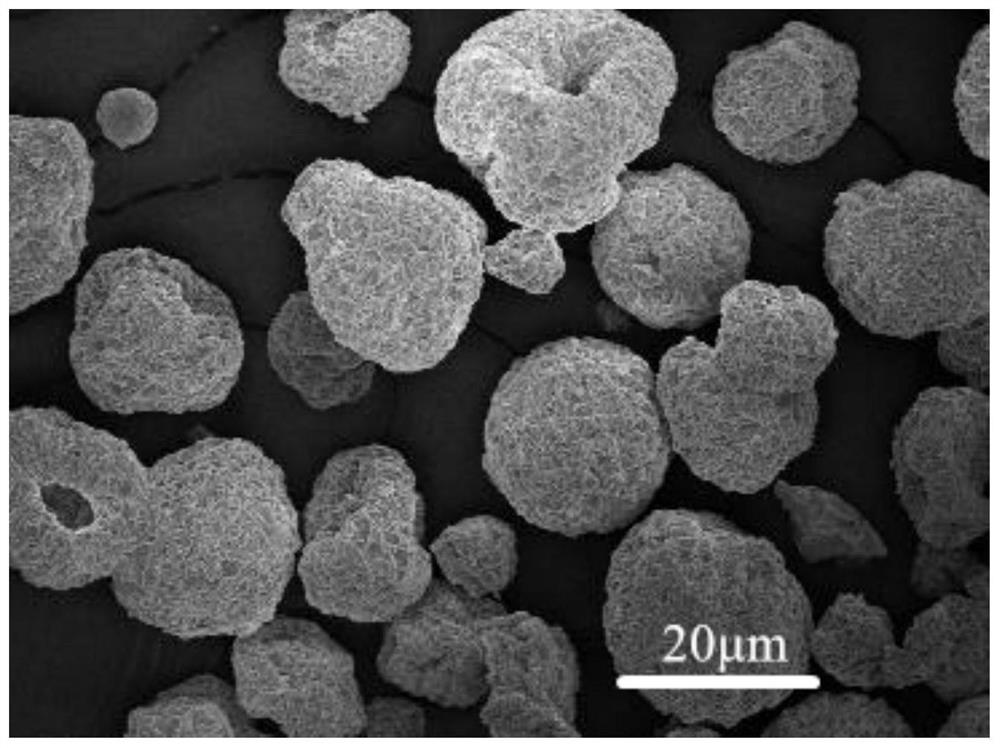

[0052] The preparation of hollow magnesium silicate-based composite adsorption material microspheres comprises the following steps:

[0053] (1) Add 300 mL of 0.8 mol / L sodium silicate solution into the reaction kettle, and adjust its pH to 11.26 with a sulfuric acid solution with a hydrogen ion concentration of 0.1 mol / L, slowly dissolve 150 mL of 0.8 mol / L magnesium sulfate solution Add it into the sodium silicate solution, control the reaction temperature to 55° C., react for 90 minutes, and stir at 100 rpm to obtain magnesium silicate slurry.

[0054] (2) Add 95 mL of 0.8 mol / L sodium carbonate solution to the magnesium silicate slurry described in step (1), to obtain magnesium silicate magnesium carbonate composite slurry.

[0055] (3) Aging the composite slurry of magnesium silicate and magnesium carbonate in step (2) for 12 hours, filtering and washing to obtain a composite filter material of magnesium silicate and magnesium carbonate.

[0056] (4) Magnesium silicate m...

Embodiment 2

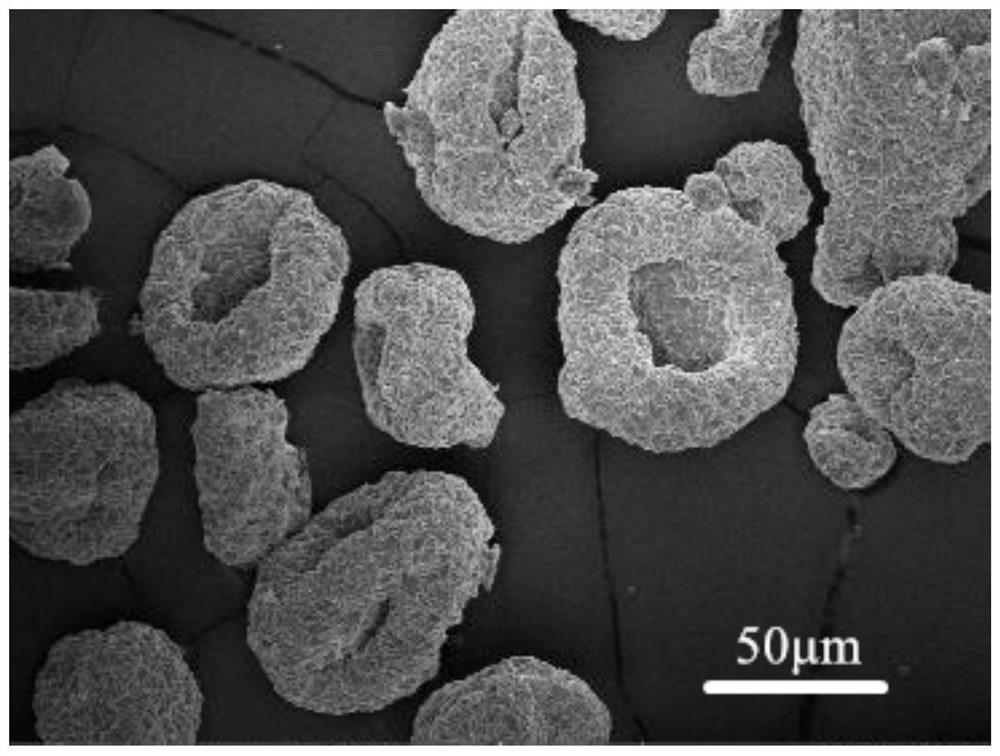

[0059] The preparation of hollow magnesium silicate-based composite adsorption material microspheres comprises the following steps:

[0060] (1) Add 3L of 0.1mol / L potassium silicate solution into the reaction kettle, adjust the pH to 11.39 with hydrochloric acid solution with a hydrogen ion concentration of 3mol / L, and slowly add 1.5L of 0.1mol / L magnesium chloride solution In the potassium silicate solution, the reaction temperature was controlled to be 10° C., the reaction time was 60 minutes, and the stirring rate was 60 rpm to obtain magnesium silicate slurry.

[0061] (2) Add 0.43L of potassium bicarbonate solution 0.43L of 0.1mol / L and 0.43L of potassium carbonate solution of 0.1mol / L in the magnesium silicate slurry described in step (1), obtain magnesium silicate magnesium carbonate composite slurry .

[0062] (3) Aging the composite slurry of magnesium silicate and magnesium carbonate in step (2) for 3 hours, filtering and washing to obtain a composite filter materi...

Embodiment 3

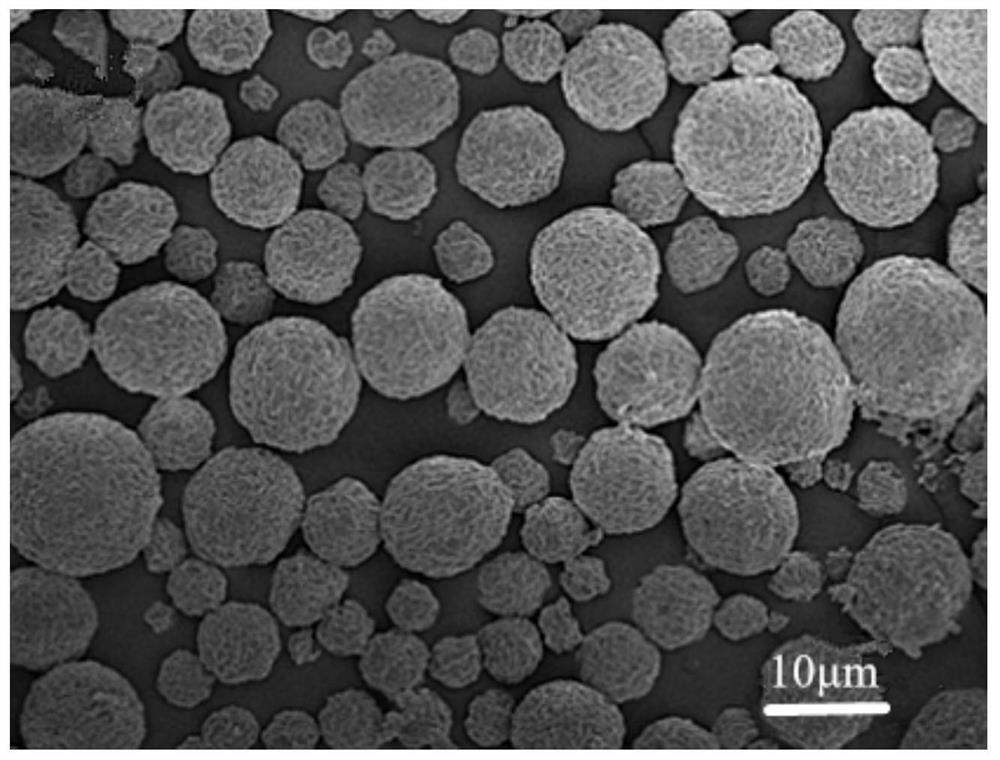

[0066] The preparation of magnesium silicate-based composite adsorption material microspheres comprises the following steps:

[0067] (1) Add 20L of 1.3mol / L sodium silicate solution in the reactor, and use a hydroxide ion concentration of 1.5mol / L sodium hydroxide solution to adjust its pH to 11.94, and 1.3mol / L magnesium sulfate 10 L of the solution was slowly added into the sodium silicate solution, the reaction temperature was controlled to be 80° C., the reaction time was 120 minutes, and the stirring rate was 130 rpm to obtain a magnesium silicate slurry.

[0068] (2) Add 4 L of 1.3 mol / L sodium bicarbonate solution to the magnesium silicate slurry described in step (1), to obtain magnesium silicate magnesium carbonate composite slurry.

[0069] (3) Aging the composite slurry of magnesium silicate and magnesium carbonate in step (2) for 18 hours, filtering and washing to obtain a composite filter material of magnesium silicate and magnesium carbonate.

[0070] (4) Magne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com