Process for treating porous carbon supports for noble metal catalysts

A technology of precious metal catalysts and treatment methods, applied in the direction of catalyst carriers, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of less treatment, achieve simple methods, high yields, and improve surface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Carbon nanotube processing method

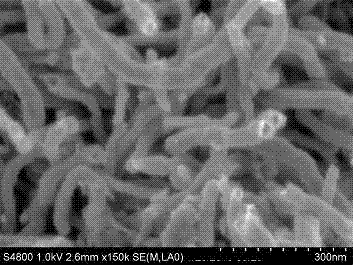

[0026] Add 100 grams of carbon nanotubes to the three-necked flask, control the temperature to 20 degrees, slowly add 200 ml of concentrated nitric acid (also an oxidant) under stirring, control the temperature to 120 degrees, and reflux the concentrated nitric acid for 12 hours to obtain the product. The product was washed with deionized water, dried at 100 degrees, and calcined in a hydrogen-argon mixture (5% hydrogen) at 500 degrees for 3 hours to obtain the treated product. figure 1 SEM picture of the product.

Embodiment 2

[0028] Porous carbon treatment method

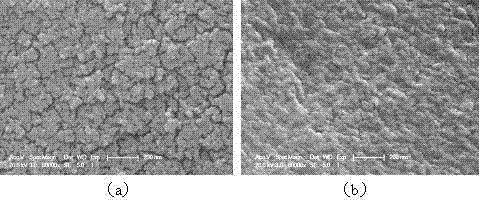

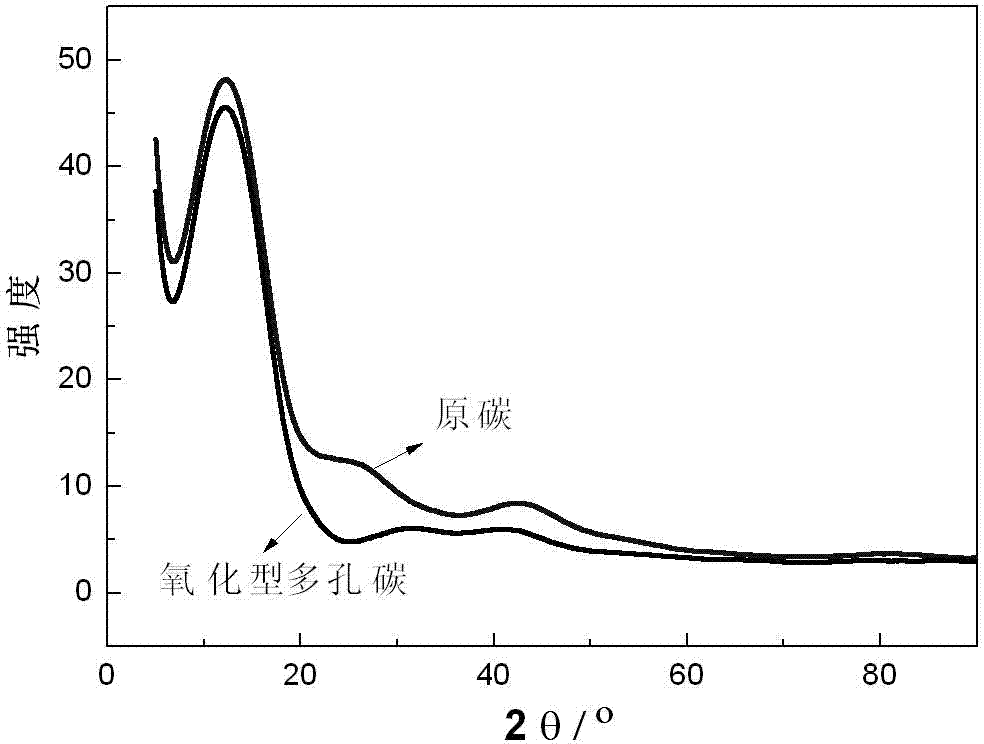

[0029] (1) Preparation method of oxidized porous carbon

[0030] Add 120g NaNO to the three-necked bottle 3 , slowly add 1000 ml of concentrated H with stirring 2 SO 4 , heat up to 40 degrees and stir until dissolved; cool the acid solution with an ice-water bath, then add 240 grams of porous carbon to the acid solution, and stir for 0.5 hours; then slowly add KMnO in an ice-water bath 4 , after the addition, react for 5-10 minutes until the exotherm stops, remove the ice-water bath, use an oil bath to heat the reaction solution to about 40 degrees, and react under stirring for 2-4 hours. After the reaction was completed, it was replaced with a condensing device, the circulating water was turned on, 2000 ml of deionized water was slowly added, and the temperature was maintained at about 98-100° C. while adding deionized water, and the reaction was performed for 4 hours. After the reaction, the oil bath was removed, deionized water wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com