A kind of preparation method of porous silicon/carbon composite material

A technology of carbon composite materials and porous silicon, applied in nanotechnology, electrical components, electrochemical generators, etc. for materials and surface science, can solve problems such as complex synthesis process, complex process, and unsuitability for large-scale production , to achieve high Coulombic efficiency and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Mix magnesium silicide and polyvinyl alcohol in a ratio of 1:0.5, put them in a ball mill tank, and carry out ball milling at a speed of 500 rpm and a ball milling time of 4 hours;

[0038] (2) The product after the reaction in (1) is placed in a high-temperature treatment furnace for two-step heat treatment. The reaction temperature is 300 degrees Celsius for 4 hours, then the temperature is raised to 600 degrees Celsius and the reaction is continued for 20 hours. During the whole heat treatment process, a mixture of nitrogen and air is introduced at a ratio of 10:1;

[0039] (3) Treat the product obtained in step (2) in a mixed acid of hydrochloric acid / hydrofluoric acid for 4 hours, the concentration of hydrochloric acid is 1 mol / liter, and the volume content of hydrofluoric acid is 5%; the reaction product is centrifuged, then dried, A porous silicon / carbon composite material is obtained.

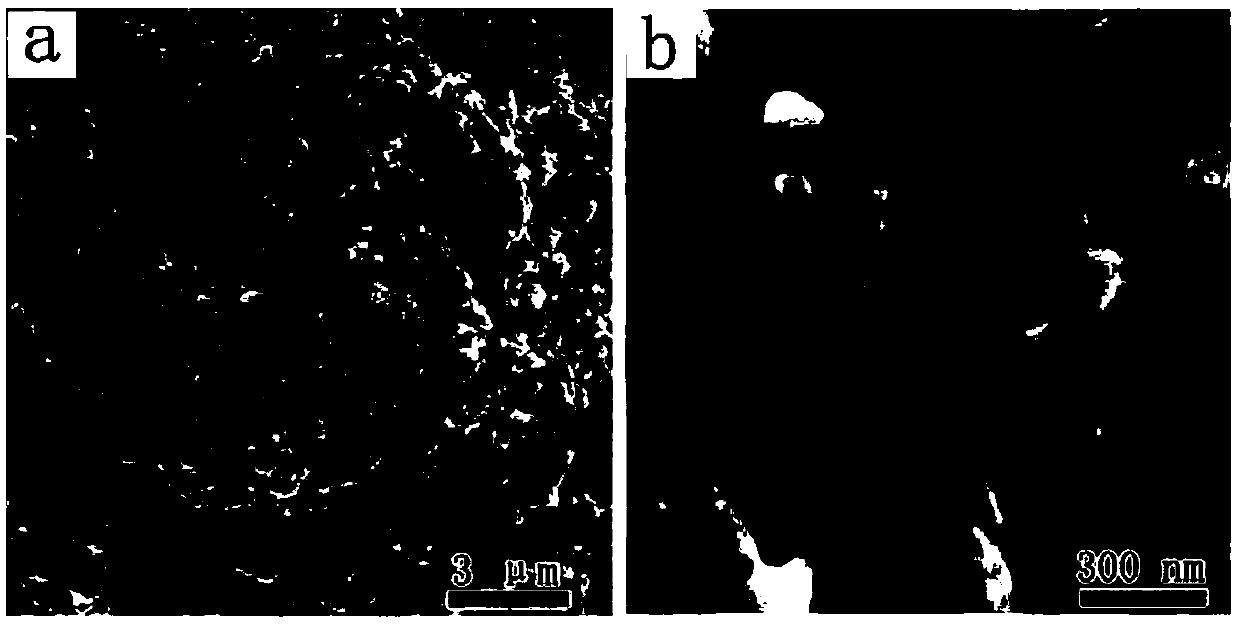

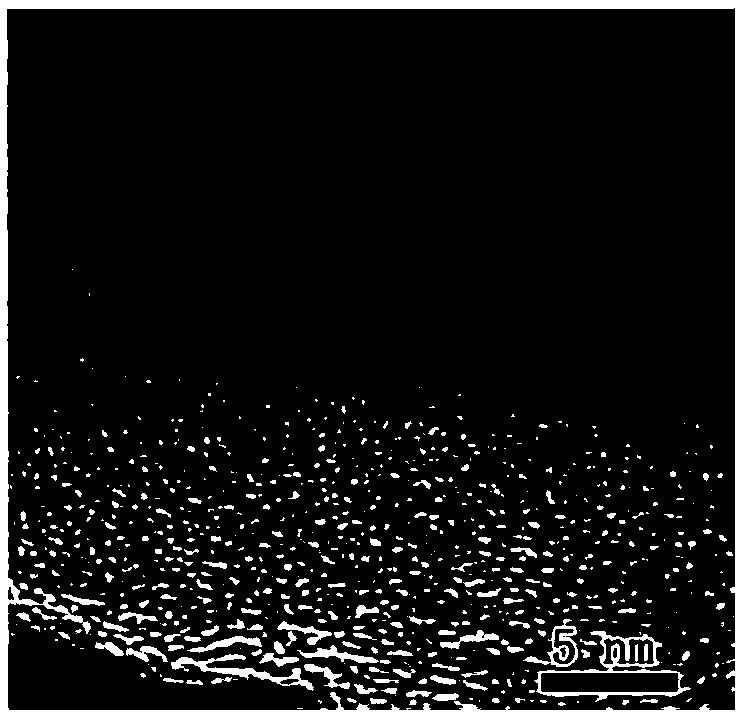

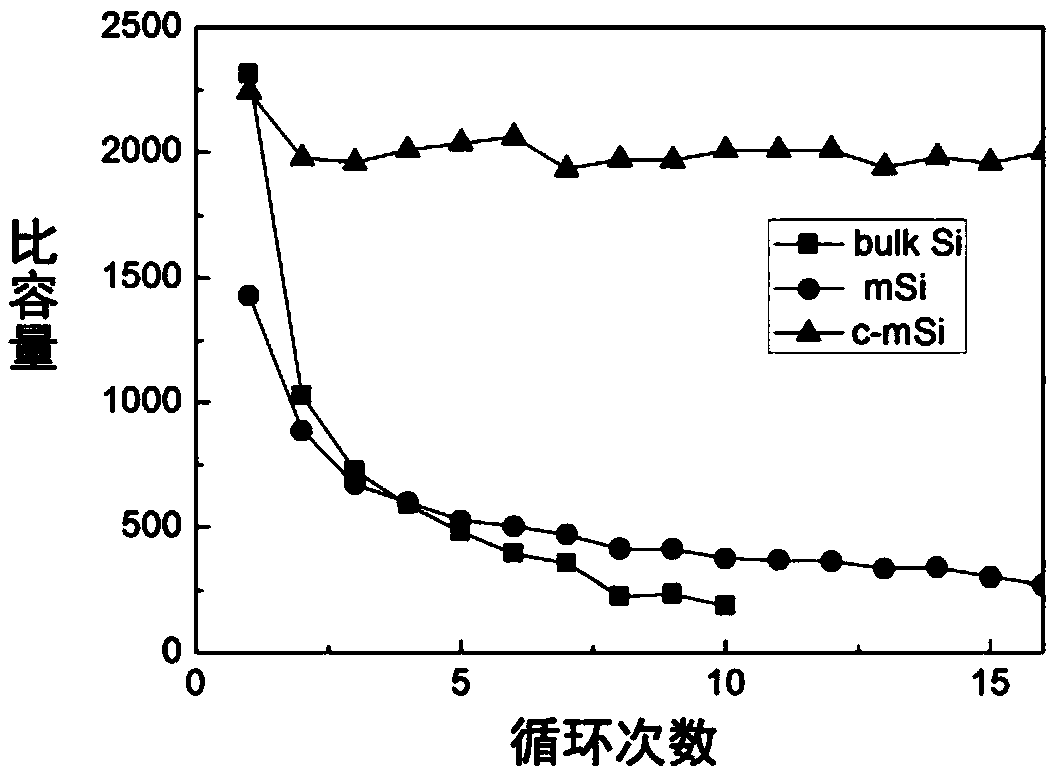

[0040] figure 1 The SEM images of the porous silicon / carbon composite ma...

Embodiment 2

[0043] (1) Mix magnesium silicide and polyvinyl alcohol in a ratio of 1:1, put them in a ball mill tank, and carry out ball milling at a speed of 500 rpm and a ball milling time of 4 hours;

[0044] (2) The product after the reaction in (1) is placed in a high-temperature treatment furnace for two-step heat treatment. The reaction temperature is 300 degrees Celsius for 4 hours, then the temperature is raised to 600 degrees Celsius and the reaction is continued for 20 hours. During the whole heat treatment process, a mixture of protective nitrogen and air is introduced, the ratio is 20:1;

[0045] (3) Treat the product obtained in step (2) in a mixed acid of hydrochloric acid / hydrofluoric acid for 4 hours, the concentration of hydrochloric acid is 0.5 mol / liter, and the volume content of hydrofluoric acid is 10%; the reaction product is centrifuged, then dried, A porous silicon / carbon composite material is obtained. The characterization of the composite was similar to Example ...

Embodiment 3

[0047] (1) Mix magnesium silicide and polyvinyl alcohol in a ratio of 1:0.5, put them in a ball mill tank, and carry out ball milling at a speed of 500 rpm and a ball milling time of 4 hours;

[0048] (2) The product after the reaction in (1) is placed in a high-temperature treatment furnace for two-step heat treatment. The reaction parameter is 350 degrees Celsius for 6 hours, then the temperature is raised to 600 degrees Celsius and the reaction is continued for 12 hours. During the whole heat treatment process, a mixture of protective gas and air is introduced, the ratio is 50:1;

[0049] (3) Treat the product obtained in step (2) in a mixed acid of hydrochloric acid / hydrofluoric acid for 4 hours, the concentration of hydrochloric acid is 2 mol / liter, and the volume content of hydrofluoric acid is 5%; the reaction product is centrifuged, then dried, A porous silicon / carbon composite material is obtained. The characterization of the composite was similar to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com