Preparation method of mesopore-controllable magnetic microsphere

A magnetic microsphere and mesoporous technology, applied in the direction of ferric oxide, iron oxide/iron hydroxide, etc., can solve the problems of low magnetic response, low crystallinity, small particle size, etc., and achieve high magnetic Responsiveness, good dispersion, and narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

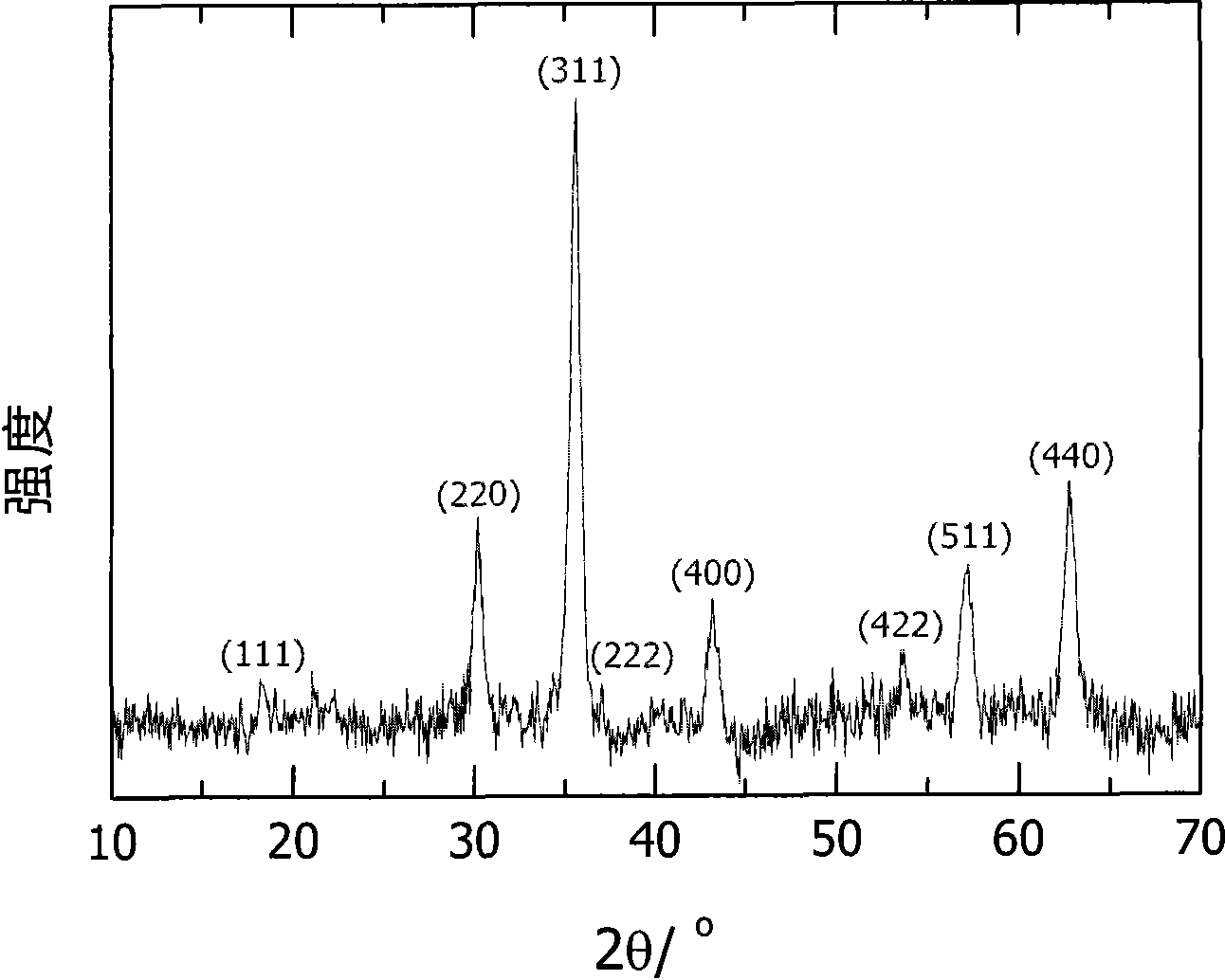

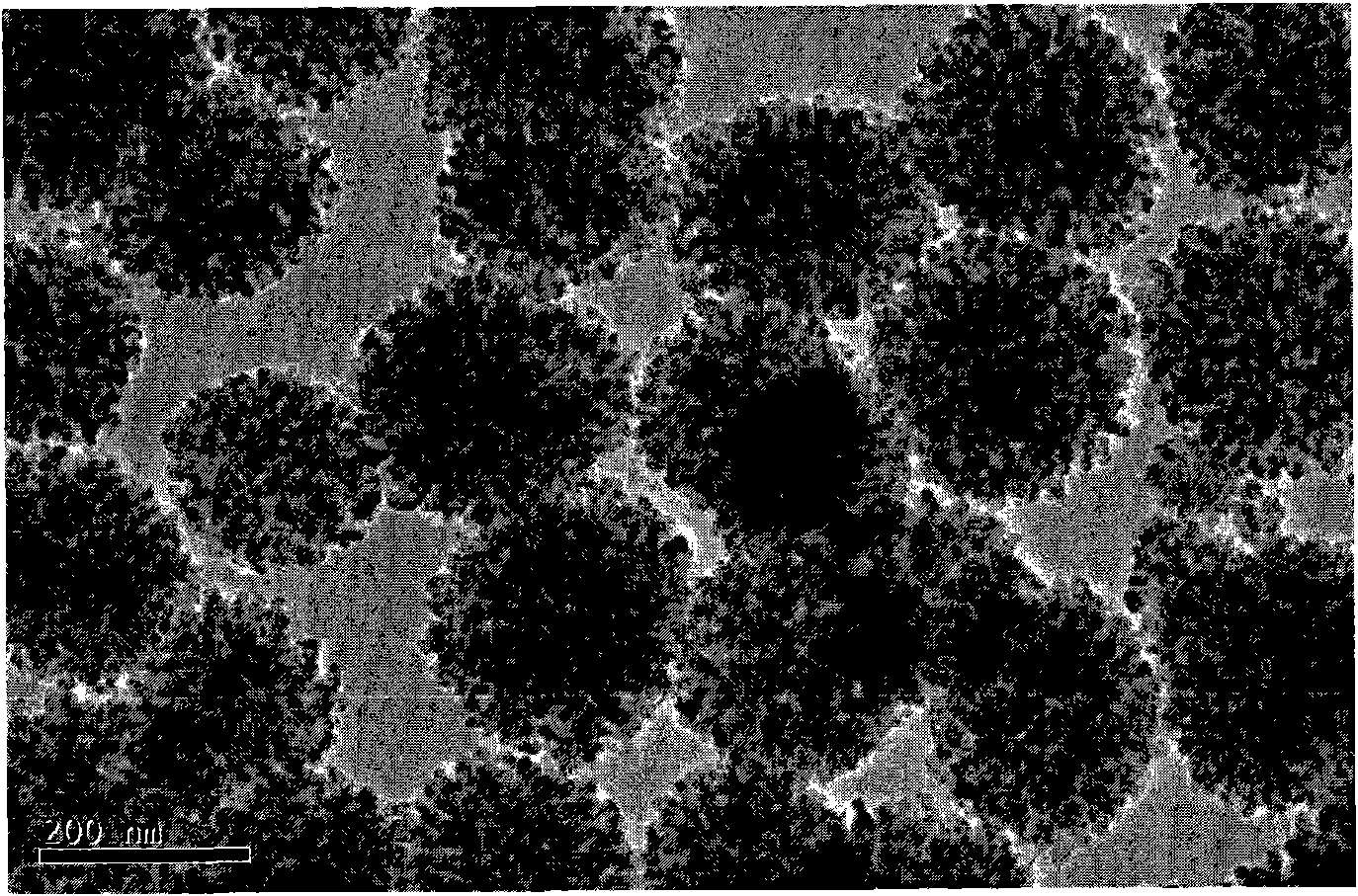

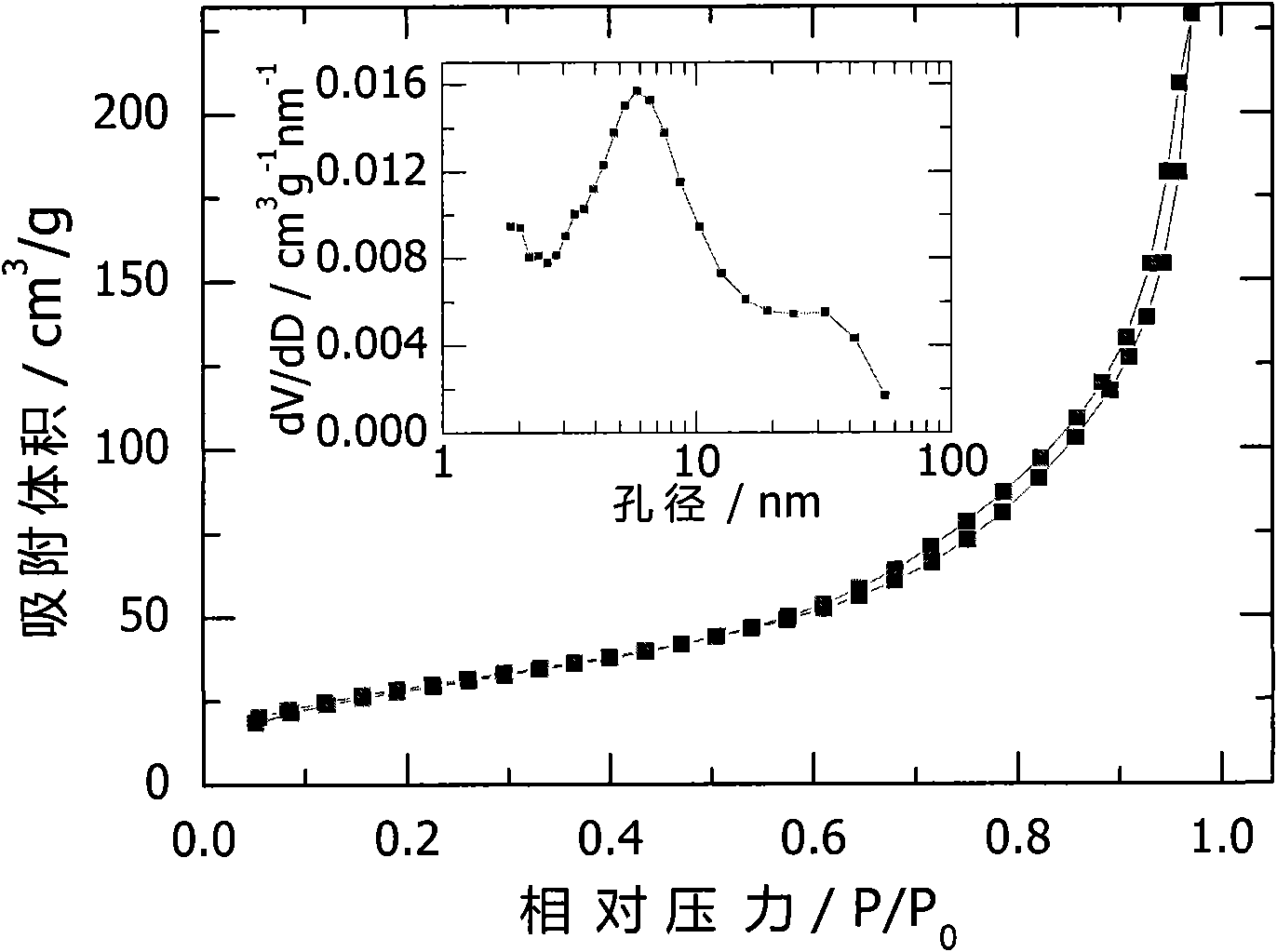

[0023] Take 16mmol of ferric chloride, 50mmol of ammonium acetate, and 0.5g of polyglutamic acid with a molecular weight of 1000kDa and add it to a 50ml hydrothermal kettle, add 40ml of ethylene glycol solution to the kettle, dissolve it, and heat it at 200°C After 8 hours, the obtained black precipitate was washed with deionized water and dried between 40°C and 80°C to obtain mesoporous ferroferric oxide magnetic microspheres. Figure 1-3 It is the result of characterizing by powder X-ray diffraction, transmission electron microscope and nitrogen adsorption-desorption isotherm curve. The particle size of the microsphere is 436nm, and the specific surface area is 182m 2 / g, the pore volume is 0.65cm 3 / g, the average pore size can be controlled at 5.8nm.

Embodiment 2

[0025] Take 2mmol of ferric chloride, 50mmol of ammonium acetate, and 0.5g of polyglutamic acid with a molecular weight of 1000kDa and add them to a 50ml hydrothermal kettle, add 40ml of ethylene glycol solution to the kettle, dissolve and heat at 250°C After 8 hours, the obtained black precipitate was washed with deionized water and dried between 40°C and 80°C to obtain mesoporous ferroferric oxide magnetic microspheres. The particle size of the microsphere is 49nm, and the specific surface area is 270m 2 / g, the pore volume is 1.35cm 3 / g, the average pore size can be controlled at 2.5nm.

Embodiment 3

[0027] Get 16mmol of ferric nitrate, 50mmol of ammonium acetate, 0.5g of polyglutamic acid with a molecular weight of 1000kDa and add them to a 50ml hydrothermal kettle, add 40ml of ethylene glycol solution to the kettle, after dissolving, heat at 300°C for 8 hours, the obtained black precipitate was washed with deionized water and dried at 40-80° C. to obtain mesoporous ferroferric oxide magnetic microspheres. The particle size of the microsphere is 407nm, and the specific surface area is 210m 2 / g, the pore volume is 0.75cm 3 / g, the average pore size can be controlled at 5.1nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com