High-purity trimanganese tetroxide and preparation method thereof

A technology of trimanganese tetraoxide and manganese hydroxide, which is applied in the direction of manganese oxide/manganese hydroxide, etc., can solve the problems of lack of impurity removal means, high energy consumption of the process, and non-compliance, so as to improve the quality and scope of application, and the process is simple , the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

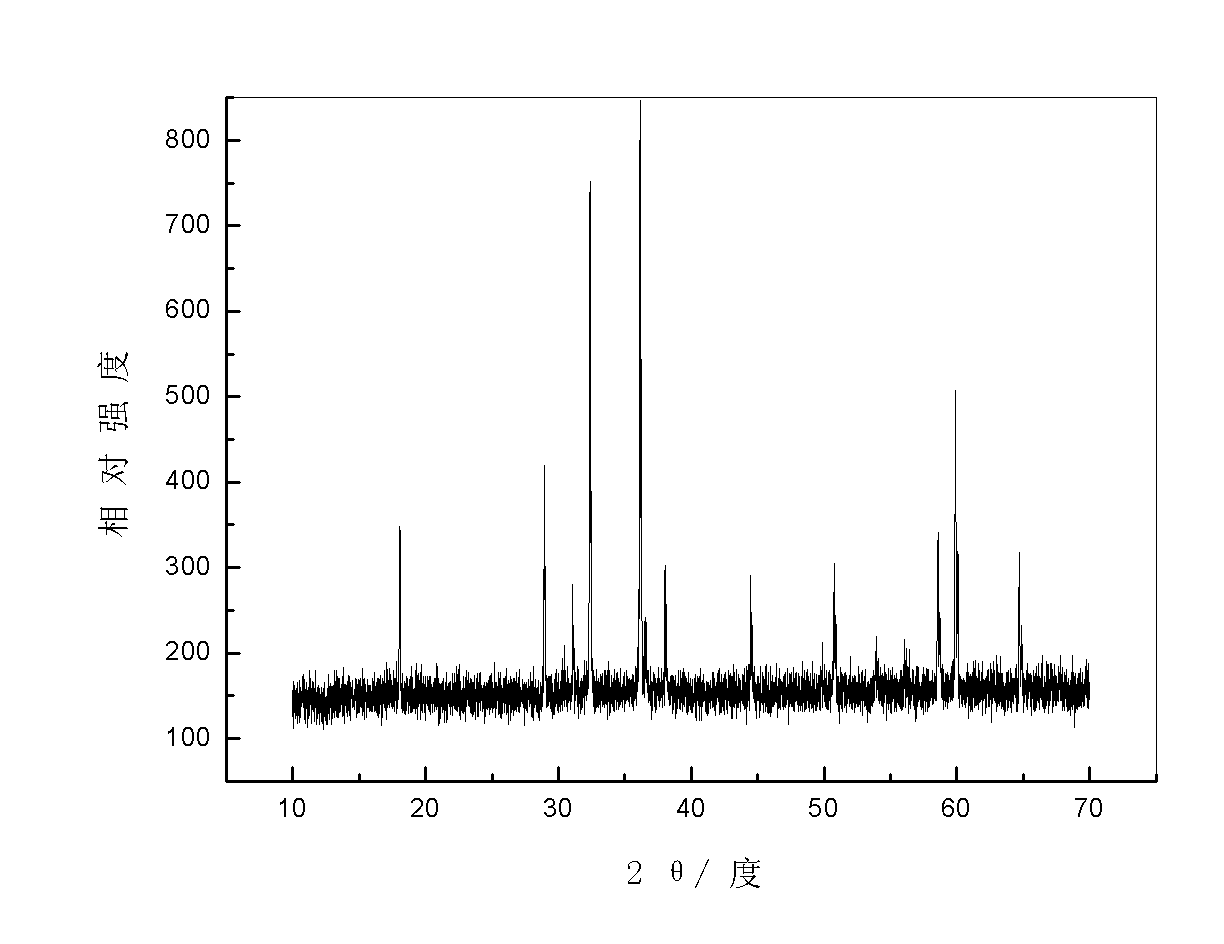

[0032] a kind of like figure 1 The high-purity trimanganese tetraoxide of the present invention shown is prepared by adopting the following method:

[0033] (1) Preparation of high-purity manganese sulfate: take ordinary manganese sulfate as raw material, obtain high-purity manganese sulfate through impurity removal, concentrated crystallization;

[0034](2) Neutralization reaction: the above-mentioned high-purity manganese sulfate is dissolved in water to obtain a manganese sulfate solution, and the Mn in the manganese sulfate solution is controlled 2+ The initial concentration is 60g / L, and then ammonia water is added dropwise to neutralize the manganese sulfate solution. The reaction temperature during neutralization is controlled at 45°C, the stirring intensity during neutralization is 150r / min, and the pH value of the neutralization system reaches 9.5~ 10.0 is used as the end point of the neutralization reaction. After the ammonia water is added dropwise, continue the he...

Embodiment 2

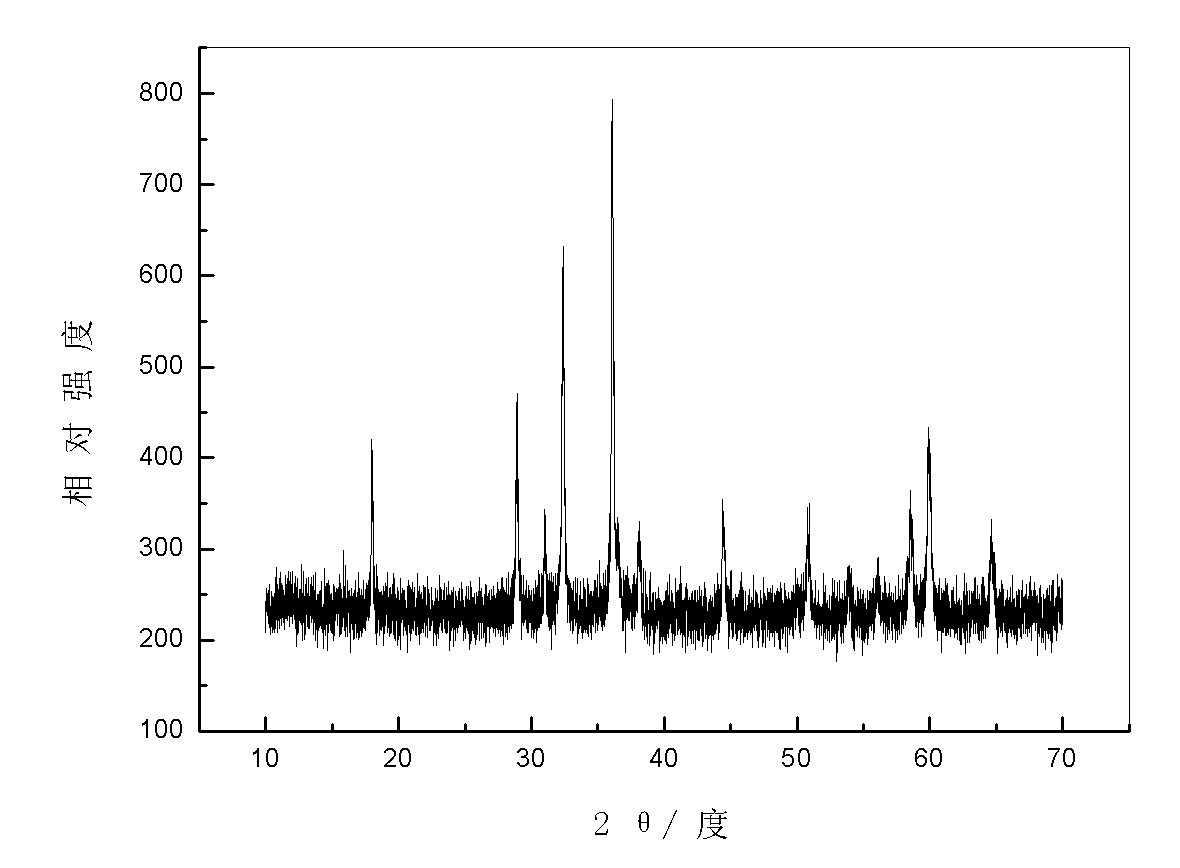

[0038] a kind of like figure 2 The high-purity trimanganese tetraoxide of the present invention shown is prepared by adopting the following method:

[0039] (1) Preparation of high-purity manganese sulfate: take ordinary manganese sulfate as raw material, obtain high-purity manganese sulfate through impurity removal, concentrated crystallization;

[0040] (2) Neutralization reaction: the above-mentioned high-purity manganese sulfate is dissolved in water to obtain a manganese sulfate solution, and the Mn in the manganese sulfate solution is controlled 2+ The initial concentration is 80g / L, and then ammonia water is added dropwise to neutralize the manganese sulfate solution. The reaction temperature during neutralization is controlled at 45°C, the stirring intensity during neutralization is 150r / min, and the pH value of the neutralization system reaches 9.5~ 10.0 is used as the end point of the neutralization reaction. After the ammonia water is added dropwise, continue the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com