Scandium-and-cerium-doped zirconium oxide ultrafine powder and preparation method thereof

An ultra-fine powder, zirconia technology, applied in zirconia and other directions, can solve the problems of zirconia powder particle size, specific surface area cannot be effectively controlled, sintering activity is not high, difficult to control and improve sample performance, etc. The effect of large-scale industrial production, simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

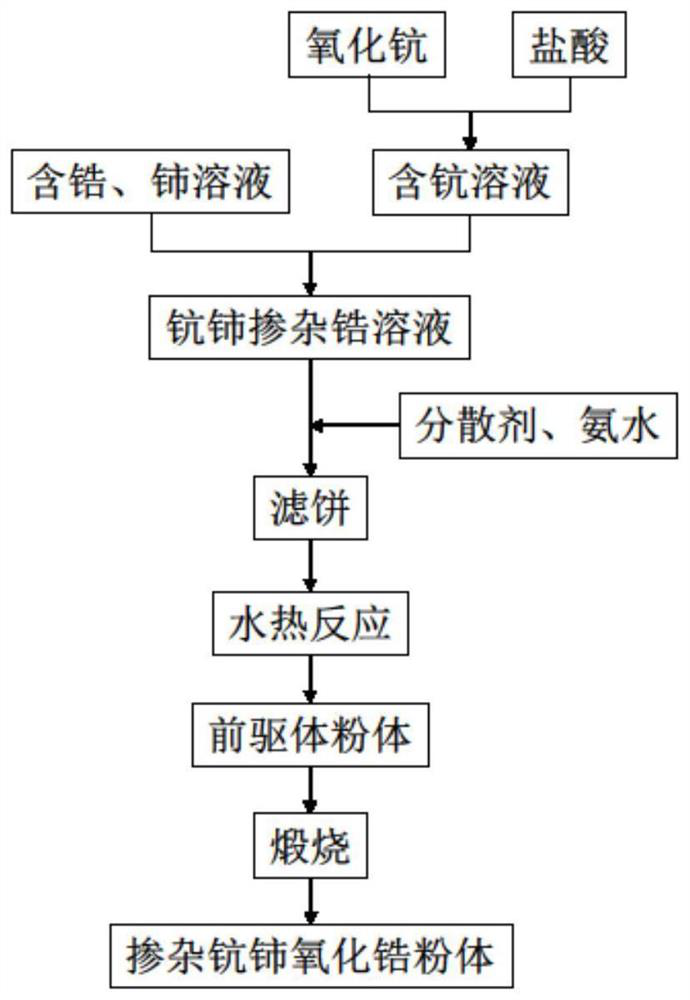

[0035] A kind of preparation method of doping scandium cerium zirconia ultrafine powder, such as figure 1 shown, including the following steps:

[0036]Step 1. Weigh 8.62g of scandium oxide in a beaker, add 6mol / L hydrochloric acid to boil and dissolve to prepare a scandium-containing solution, then weigh 385g of zirconium oxychloride octahydrate and 5.2g of cerium chloride heptahydrate and dissolve them in water, and mix with scandium-containing The solution was mixed evenly and prepared into 1L mixed salt solution;

[0037] Step 2: Add 4g of CTAB to the above mixed salt solution as a dispersant, heat and stir in a water bath until the CTAB is completely dissolved, then slowly add concentrated ammonia water dropwise to form a gel-like precipitate, keep heating and stirring in a water bath, and periodically pulverize the condensate Colloidal precipitation to avoid its complete coagulation, and the reaction ends when the pH of the solution is 9-10;

[0038] Step 3, the precip...

Embodiment 2

[0042] A kind of preparation method of doping scandium cerium zirconia ultrafine powder, such as figure 1 shown, including the following steps:

[0043] Step 1, configuration is the same as the mixed salt solution described in step 1 in Example 1;

[0044] Step 2: Add 20g of dispersant CTAB to the above mixed salt solution, heat in a water bath at 80°C and stir until CTAB is completely dissolved, then slowly add concentrated ammonia water dropwise to form a gel-like precipitate, keep the state of heating and stirring in the water bath, and periodically Crush the gel precipitate and dilute with water until the precipitate no longer coagulates, and the reaction ends when the pH of the solution is 9-10;

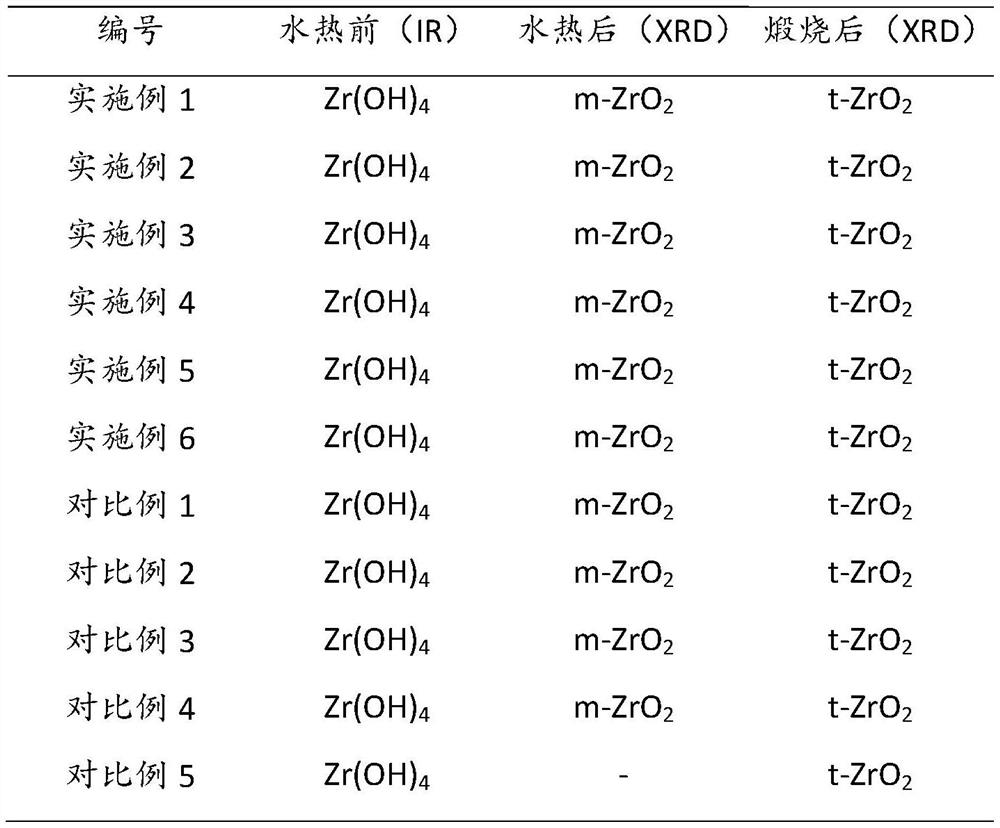

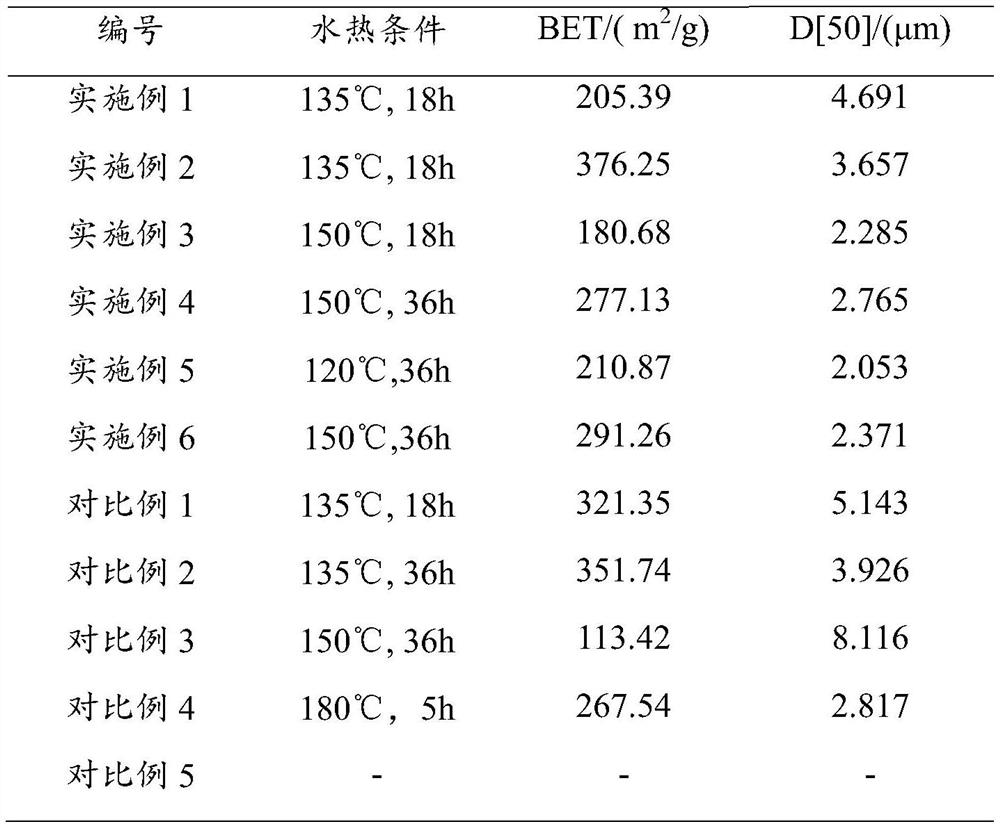

[0045] Step 3. Suction filter and wash the precipitate after the reaction to obtain a filter cake. First, take a small amount of filter cake to dry and conduct an infrared spectrum test to obtain the composition form of zirconium in it, as shown in Table 1; in addition, take an...

Embodiment 3

[0049] A kind of preparation method of doping scandium cerium zirconia ultrafine powder, such as figure 1 shown, including the following steps:

[0050] Step 1, configuration is the same as the mixed salt solution described in step 1 in Example 1;

[0051] Step 2. Add 25g of dispersant CTAB to the above mixed salt solution, heat and stir in a water bath until CTAB is completely dissolved, then slowly add concentrated ammonia water dropwise to form a gel-like precipitate, keep the state of heating and stirring in a water bath, and periodically pulverize the condensate The gel is precipitated and diluted with water until the precipitate no longer coagulates, and the reaction is completed when the pH of the solution is 9-10;

[0052] Step 3. Suction filter and wash the precipitate after the reaction to obtain a filter cake. First, take a small amount of filter cake to dry and conduct an infrared spectrum test to obtain the composition form of zirconium in it, as shown in Table 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com