Eutectic high-entropy oxide powder material and preparation method thereof

A technology of oxide powder and bulk material is applied in the field of dual-phase Mnx1-xO high-entropy oxide material and its preparation, and eutectic high-entropy oxide powder material, which can solve the problem of not finding eutectic high-entropy oxide and so on. , to achieve uniform product composition and microstructure, controllable grain size, and controllable specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

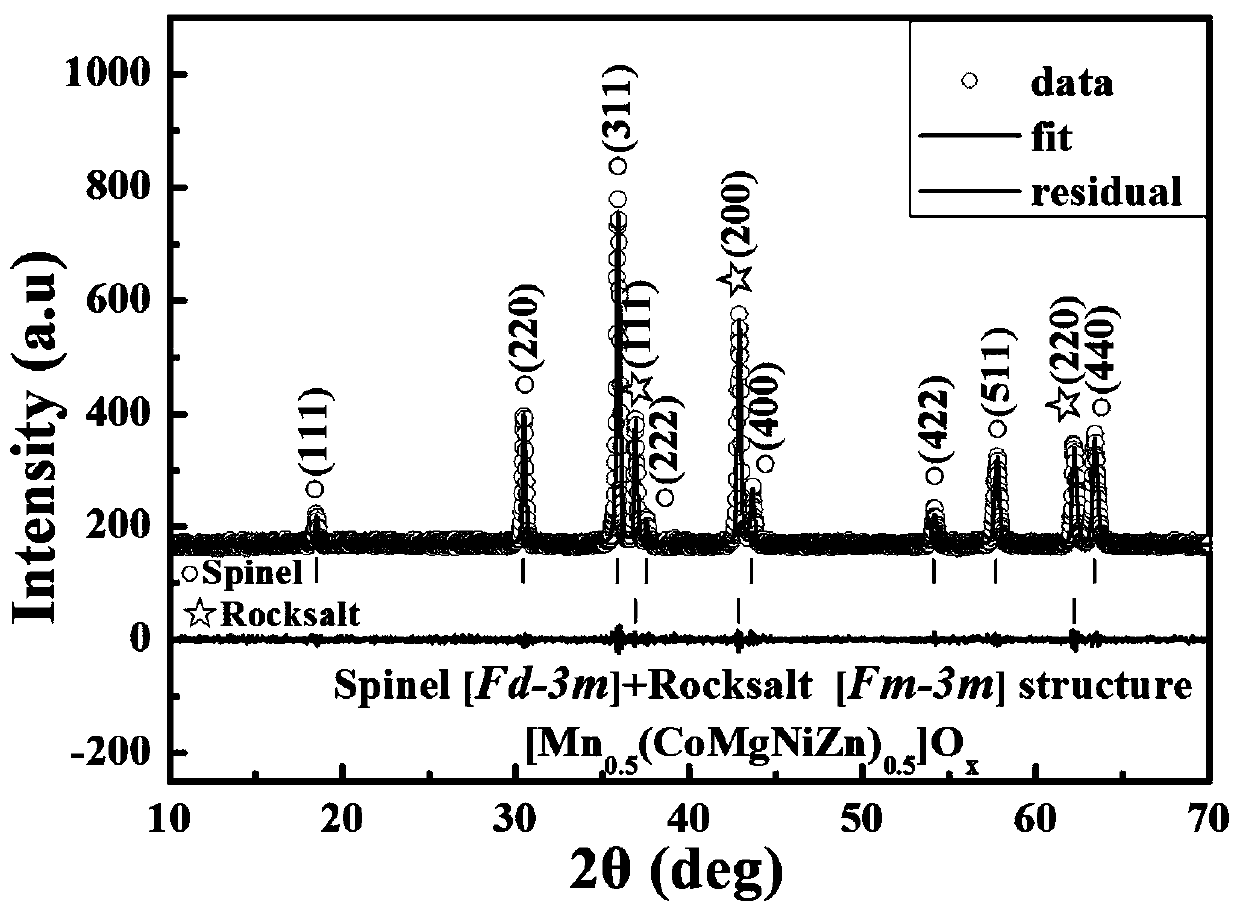

[0025] A kind of eutectic high-entropy oxide powder of the present invention is prepared by solution combustion method, and its chemical composition is [Mn 0.5 (CoMgNiZn) 0.5 ] O: take by weighing the corresponding metal nitrate according to the stoichiometric ratio of the molecular formula, specifically: 2.870g of Mn(NO 3 ) 2 ·6H 2 O, 2.910g of Co(NO 3 ) 2 ·6H 2 O, 2.564g of Mg(NO 3 ) 2 ·6H 2 O, 2.908g of Ni(NO 3 ) 2 ·6H 2 O and 2.975g of Zn(NO 3 ) 2 ·6H 2 O, dissolved in 10mL distilled water, stirred evenly at room temperature to obtain a mixed solution containing five metal cations; then weighed 7.507g glycine and added to the mixed solution, stirred evenly to obtain a transparent sol; then put the above transparent sol Dry in an oven at 850°C to obtain a viscous gel after evaporating water; finally put the above gel in a muffle furnace and keep it at 900°C for 1 hour to obtain a crystal structure of 37.1% rock-salt phase and spinel Eutectic oxide [Mn 0.5 (C...

Embodiment 2

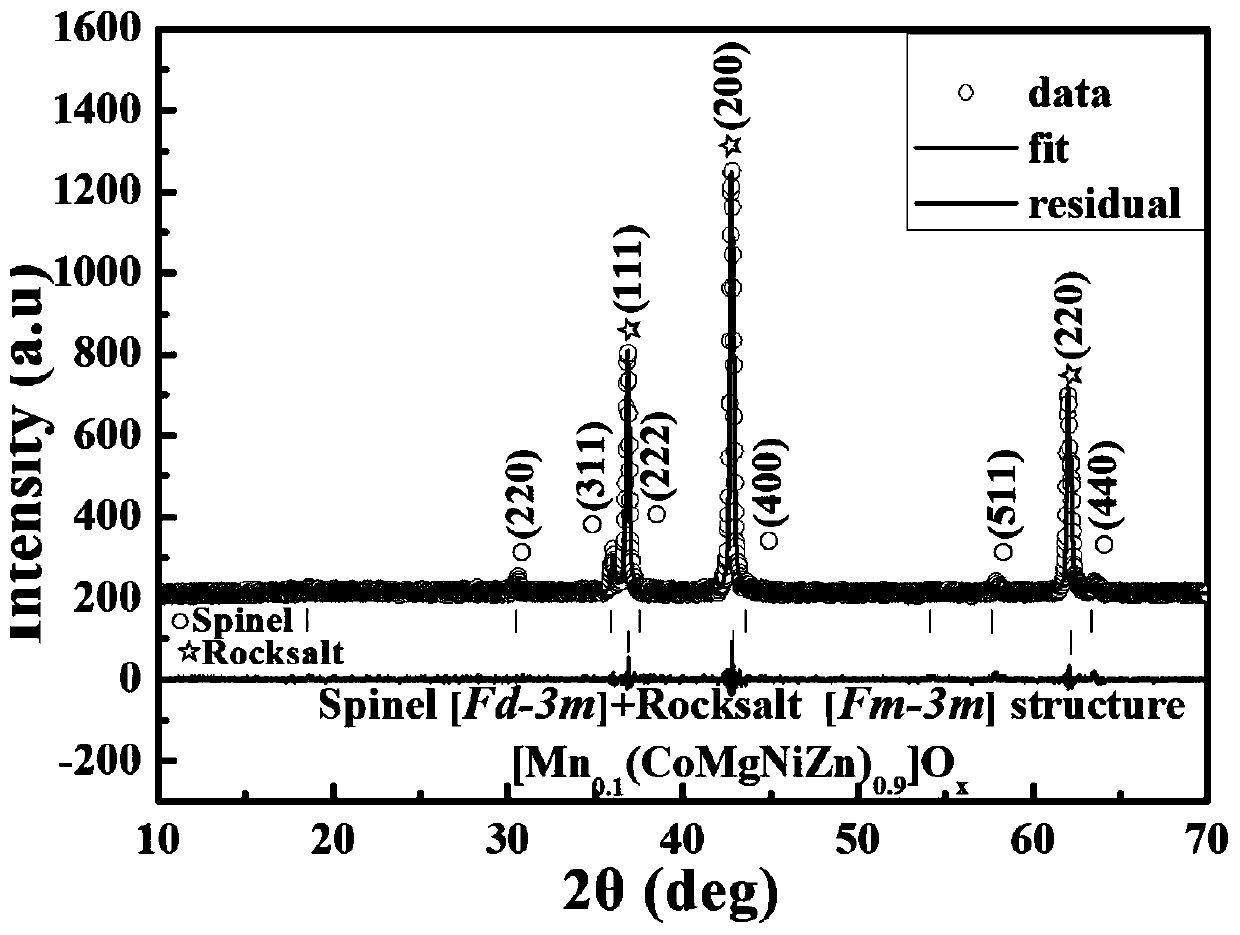

[0027] A kind of eutectic high-entropy oxide powder of the present invention is prepared by solution combustion method, and its chemical composition is [Mn 0.1 (CoMgNiZn) 0.9 ] O: take by weighing the corresponding metal nitrate according to the stoichiometric ratio of the molecular formula, specifically: 0.287g of Mn(NO 3 ) 2 ·6H 2 O, 2.619g of Co(NO 3 ) 2 ·6H 2 O, 2.308g of Mg(NO 3 ) 2 ·6H 2 O, 2.617g of Ni(NO 3 ) 2 ·6H 2 O and 2.678g of Zn(NO 3 ) 2 ·6H 2 O, dissolved in 4.5mL distilled water, stirred evenly at room temperature to obtain a mixed solution containing five metal cations; then weighed 6.666g of glucose and added to the mixed solution, stirred evenly to obtain a transparent sol; then the above transparent sol Put it in an oven at 100°C to dry, and get a viscous gel after evaporating water; finally, put the above gel in a muffle furnace and keep it at 550°C for 1 hour to obtain a crystal structure of 91.4% rock-salt phase, spinel Eutectic oxide with...

Embodiment 3

[0029] A kind of eutectic high-entropy oxide powder of the present invention is prepared by solution combustion method, and its chemical composition is [Mn 0.7 (CoMgNiZn) 0.3 ]O: Take by weighing the corresponding metal nitrate according to the stoichiometric ratio of the molecular formula, specifically 2.009g of Mn(NO 3 ) 2 ·6H 2 O, 0.873g of Co(NO 3 ) 2 ·6H 2 O, 0.769g of Mg(NO 3 ) 2 ·6H 2 O, 0.872g of Ni(NO 3 ) 2 ·6H 2 O and 0.893g of Zn(NO 3 ) 2 ·6H 2O, dissolved in 2mL distilled water, stirred evenly at room temperature to obtain a mixed solution containing five metal cations; then weighed 1.825g of citric acid and added to the mixed solution, stirred evenly to obtain a transparent sol; then the above transparent sol Put it in an oven at 100°C to dry, and get a viscous gel after evaporating water; finally, put the above gel in a muffle furnace and keep it at 950°C for 1 hour to obtain a crystal structure of 5.9% rock salt phase, spinel Eutectic oxide with 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com