Gas sensor and temperature compensation method based on Pt reaction electrode

A gas sensor and reaction electrode technology, applied to thermometers, thermometers, instruments, etc. that use electric/magnetic elements that are directly sensitive to heat, can solve problems such as temperature influence, achieve increased reaction interface, easy mass production, and temperature measurement range wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

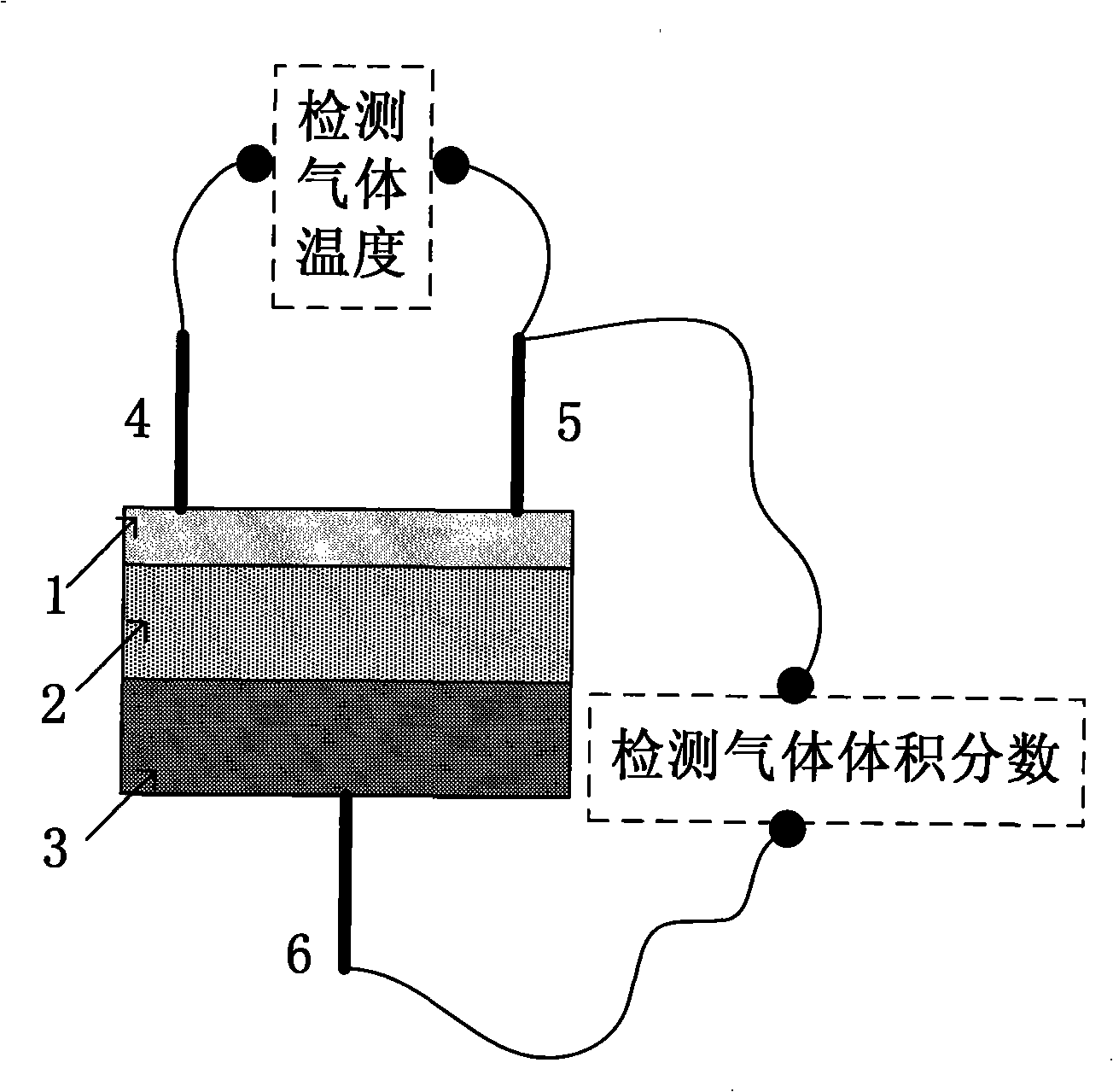

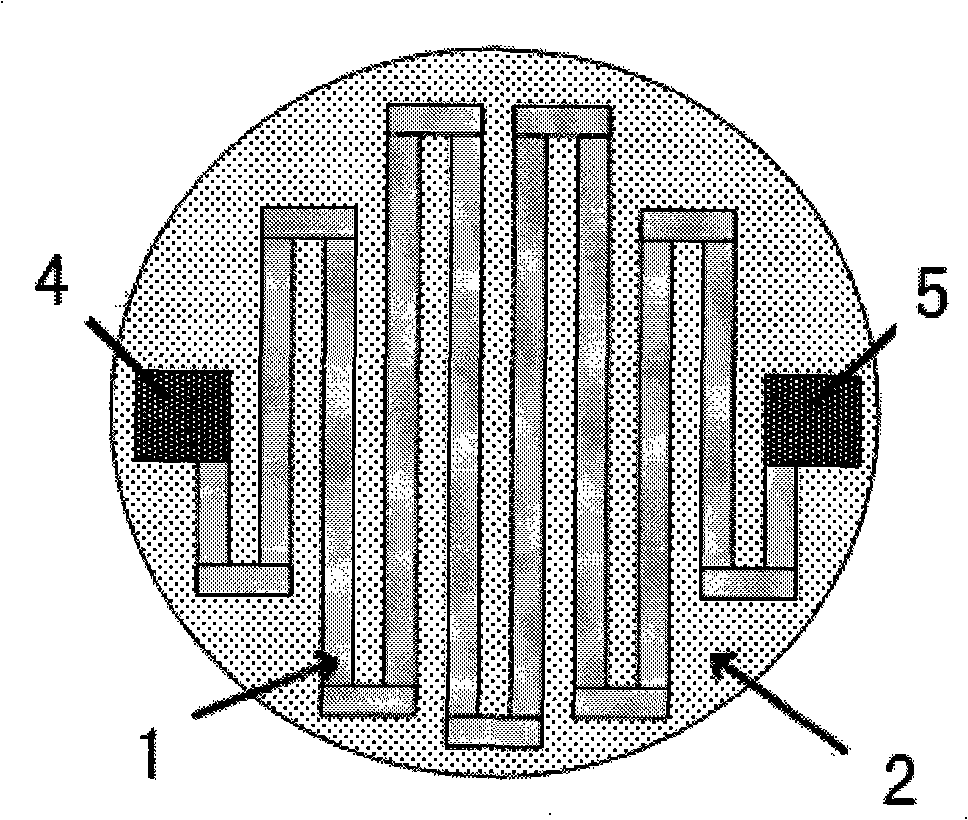

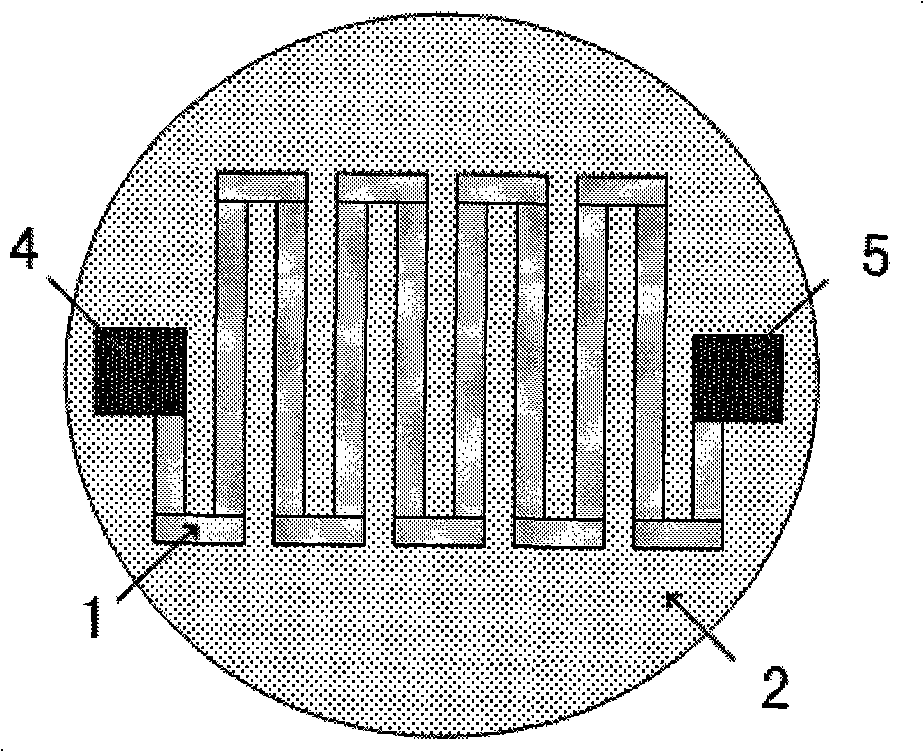

[0021] Such as figure 1 As shown, the present invention includes a LaF 3 Solid electrolyte wafer 2, Sn and SnF 2 Reference electrode 3. Using MEMS process in LaF 3 The Pt reaction electrode 1 prepared on the upper end surface of the solid electrolyte wafer 2 and two leads 5 and 6 connected to the Pt reaction electrode 1 and one lead 4 connected to the reference electrode 3 constitute a gas sensor and a temperature measurement system.

[0022] The solid electrolyte wafer 2 and the reference electrode 3 are connected by conductive adhesive. The electrochemical activity of Pt reaction electrode 1 can be used as the reaction electrode of solid electrolyte gas sensor, SO 2 , CO, CO 2 , F 2 Waiting for gas in Pt / LaF 3 A series of physical and chemical reactions occur at the interface, and the formation can be in LaF 3 Conductive O in solid electrolyte wafer 2 - , F - Ions, the conduction of these ions in the solid electrolyte wafer 2 makes the Pt reactive electrode 1 interact with Sn a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com