Three-dimensional warm-keeping knitted fabric and preparation method thereof

A knitted fabric, three-dimensional technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of insufficient thickness, inability to take into account warmth and wearing comfort, and heavy fabric weight, etc., to achieve strong heat resistance and excellent warmth retention effect, good anti-pilling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1) Selection of raw materials: 14.5tex pure cotton combed yarn is selected for the outer layer of the fabric; nylon filament is selected for the inner layer, and its single fineness is 50D.

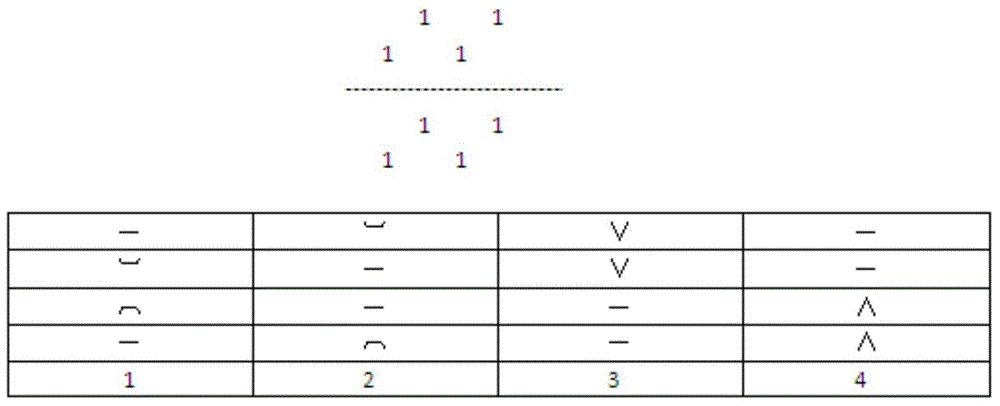

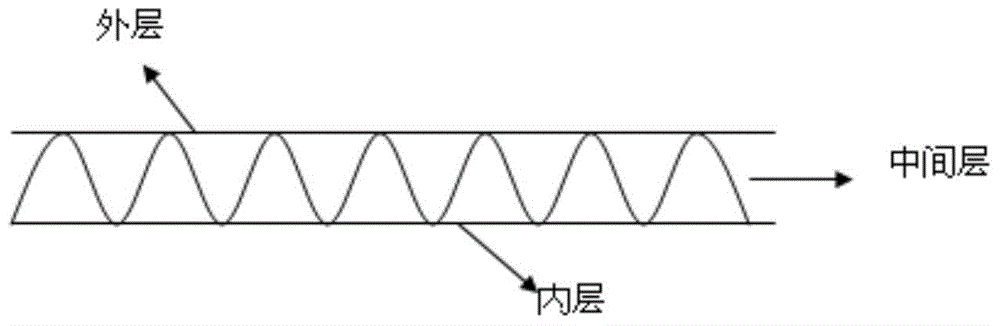

[0022] 2) Machine knitting: the fabric is processed by a double-sided circular knitting machine, and the middle layer of the fabric is passed through the intersecting tuck of the dial and the needle cylinder to connect the structure of the inner and outer layers of the fabric; the outer layer of the fabric is fully looped through the needle cylinder It is processed, and the inner layer is processed by the needle disc full circle process.

[0023] 3) Shaping: temperature 150°C, overfeed 25%, vehicle speed 25m / min.

[0024] 4) Pre-treat the fabric after the previous step with a bath ratio of 1:10, the additives are: defoamer 0.06-1.5g / L, dispersant 1-4g / L, penetrant 1-4g / L, hydrogen peroxide stabilizer 0.3~3g / L.

[0025] 5) Dyeing: Two-bath method is used for dyeing in THEN air-flo...

Embodiment 2

[0029] 1) Selection of raw materials: 18tex pure cotton combed yarn is selected for the outer layer of the fabric; polyester fiber filament is selected for the inner layer, and its single fineness is 70D.

[0030] 2) Machine knitting: the fabric is processed by a double-sided circular knitting machine, and the middle layer of the fabric is processed through the complete loop of the dial and the needle cylinder to connect the inner and outer layer structures of the fabric; the outer layer of the fabric is fully looped through the needle cylinder. It is processed, and the inner layer is processed by the needle disc full circle process.

[0031] 3) Shaping: temperature 150°C, overfeed 25%, vehicle speed 25m / min.

[0032] 4) Pre-treat the fabric after the previous step with a bath ratio of 1:10, the additives are: defoamer 0.06-1.5g / L, dispersant 1-4g / L, penetrant 1-4g / L, hydrogen peroxide stabilizer 0.3~3g / L.

[0033] 5) Dyeing: Two-bath method is used for dyeing in THEN air-fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com