Cotton carbon cloth/nitrogen-doped nanocarbon/carbon nanotube flexible integrated electrode and preparation method and application thereof

A nitrogen-doped nanocarbon and carbon nanotube technology, applied in the field of electrocatalytic materials, can solve the problems of limited application of flexible zinc-air battery development, inapplicability, etc., and achieve excellent zinc-air battery performance, firm load structure, good The effect of interface conducting interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

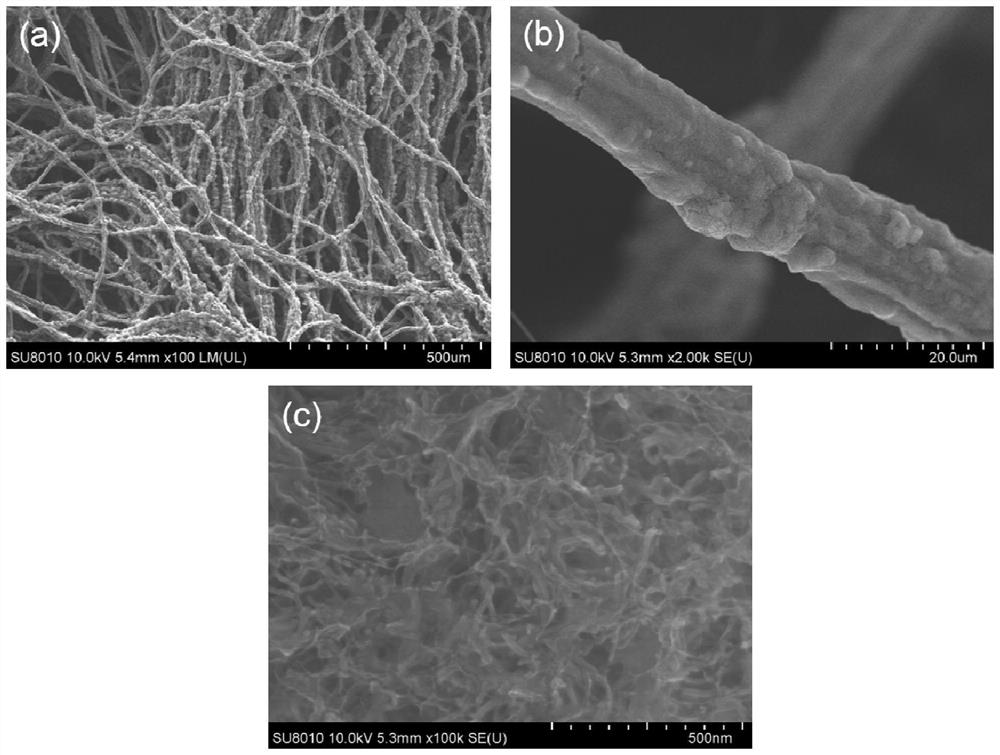

[0038] The preparation method of CCC-NC-CNT-1.5 integrated electrode includes the following steps:

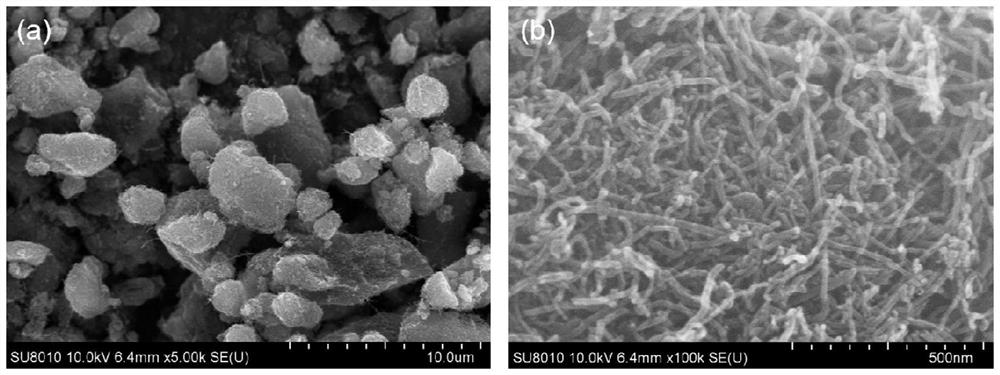

[0039] (1) Solution self-assembly process of powdered carbon nanotubes on a cotton flexible substrate: Add 0.01 g of carbon nanotube (CNT) powder and 5 mL of water into a beaker, and ultrasonically disperse it at room temperature for 5 min to make the carbon nanotube powder in Disperse evenly in the aqueous solution; then, add 1.5g of urea to the solution, and stir at room temperature until the urea (Urea) is completely dissolved to form a uniform mixed solution; finally, a piece of about 2.5*5cm in size 2 The cotton cloth was soaked in the mixed solution for 1 h to fully absorb the solution slurry, and the effective self-assembly and combination of powder carbon nanotubes on the cotton cloth was realized, and the uncarbonized cotton cloth+urea+carbon nanotube precursor sheet was obtained, Labeled as CC+Urea+CNT.

[0040] (2) Calcination and carbonization to obtain a solidly l...

Embodiment 2

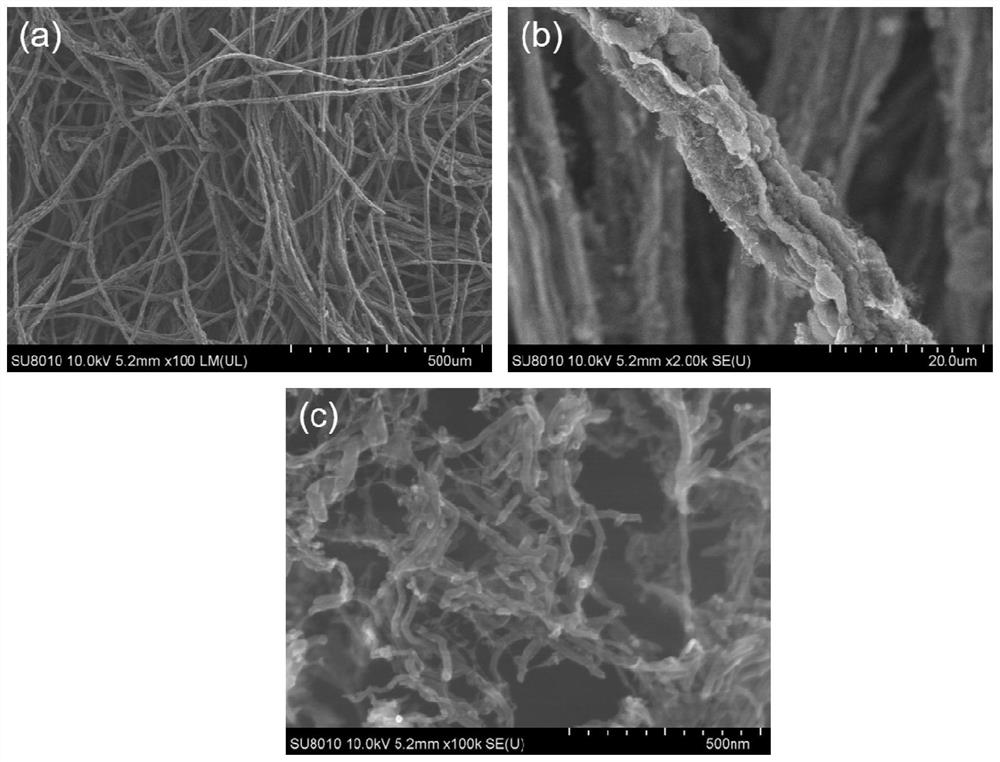

[0045] Preparation method of CCC-NC-CNT-0.75 integrated electrode:

[0046] The difference with Example 1 is that in step (1), then, add urea to the solution, fully stir 10min at room temperature, until the urea is completely dissolved to form a homogeneous mixed solution; the amount of the added urea is changed to 0.75 g, the last obtained sample was labeled CCC-NC-CNT-0.75.

Embodiment 3

[0048] Preparation method of CCC-NC-CNT-3 integrated electrode:

[0049] The difference with Example 1 is that in step (1), then, add urea to the solution, fully stir 10min at room temperature, until the urea is completely dissolved to form a homogeneous mixed solution; the amount of the added urea is changed to 3 g, and the finally obtained sample was labeled as CCC-NC-CNT-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com